Roughing roll made of graphitizable steel material and manufacturing method thereof

A manufacturing method and technology of graphite steel, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of roll thermal cracks, poor thermal crack resistance, online wear, etc., and achieve small hardness drop, improved crack resistance, and durability Good grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

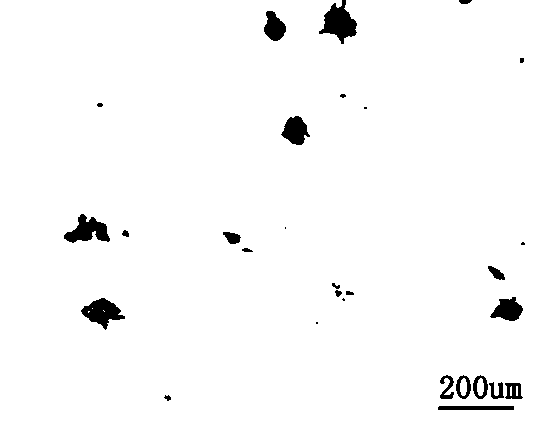

Embodiment 1

[0026] In this embodiment, the design targets for the alloy composition and weight percentage of the rough roll made of wear-resistant graphite steel are C: 1.20-1.60%, Si: 1.00-1.30%, Mn: 0.50-0.70%, P≤0 .02%; S≤0.02%, Cr: 0.40~1.10%, Ni: 0.20~0.90%, Mo: 0.20~0.40%, and the rest are Fe and unavoidable impurities.

[0027] The manufacture method of the rough roll of this wear-resistant type graphite steel material is:

[0028] A. Make a mold with the aid of a molding machine.

[0029] B. Select the raw materials according to the content ratio of each alloy element in the design target and put them into the electric arc furnace for melting by oxidation method. The melting temperature is 1500℃~1600℃ and the heating rate is 50℃ / h. During the melting process, prevent P and C increase during the reduction period. During the reduction period, use white slag to deoxidize, and use carbon powder and ferrosilicon powder to increase carbon before tapping to ensure that the chemical comp...

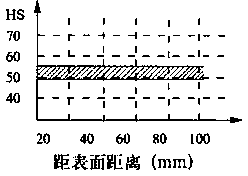

Embodiment 2

[0038] This embodiment adopts the same manufacturing method as Embodiment 1, and its difference is:

[0039] The design targets of the alloy composition and weight percentage of the wear-resistant graphite steel rough roll are C: 1.60-2.00%, Si: 1.30-1.90%, Mn: 0.70-1.00%, P≤0.02% ; S≤0.02%, Cr: 1.10-2.50%, Ni: 0.90-1.30%, Mo: 0.40-0.80%, and the rest are Fe and unavoidable impurities.

[0040] In this embodiment, the chemical composition of the blank is analyzed, and the chemical composition and weight percentage are C: 1.60%, Si: 1.50%, Mn: 0.80%, P≤0.01%; S≤0.01%, Cr : 1.40%, Ni: 1.00%, Mo: 0.60%, the rest is Fe and unavoidable impurities.

[0041] In this embodiment, the inspection of qualified products shows that the hardness of the working layer of the rough roll is 51-53HSD, and the hardness uniformity is ≤3HSD. The tensile strength of the roll neck of the rough roll was 565 MPa.

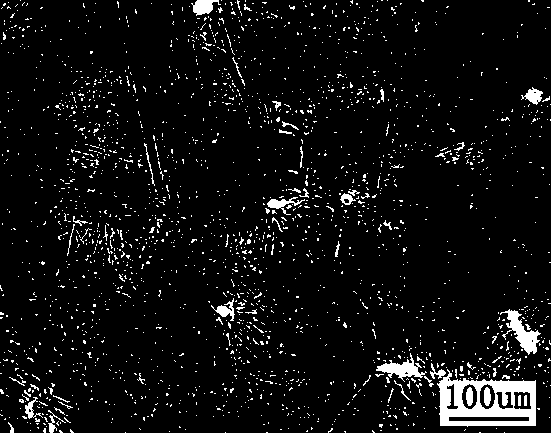

Embodiment 3

[0043] This embodiment adopts the same manufacturing method as Embodiment 1, and its difference is:

[0044] The design targets of the alloy composition and weight percentage of the rough roll made of wear-resistant graphite steel are C: 2.00-2.30%, Si: 1.90-2.20%, Mn: 1.00-1.20%, P≤0.03% ; S≤0.03%, Cr: 2.50-3.50%, Ni: 1.30-2.00%, Mo: 0.80-1.00%, and the rest are Fe and unavoidable impurities.

[0045] In this embodiment, the chemical composition of the blank is analyzed, and the chemical composition and weight percentage are C: 2.10%, Si: 2.00%, Mn: 1.10%, P≤0.02%; S≤0.03%, Cr : 2.80%, Ni: 1.70%, Mo: 0.90%, the rest is Fe and unavoidable impurities.

[0046] In this embodiment, the inspection of qualified products shows that the hardness of the working layer of the rough roll is 48-50HSD, and the hardness uniformity is ≤4HSD. The tensile strength of the roll neck of the rough roll was 510 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com