Calcination cleaning method of spinneret plate

A cleaning method and spinneret technology, applied to spinneret assemblies, textiles, and papermaking, can solve problems that affect the production process, reduce corrosion, and dimensional deformation, and achieve the effect of inhibiting metal corrosion and ensuring structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

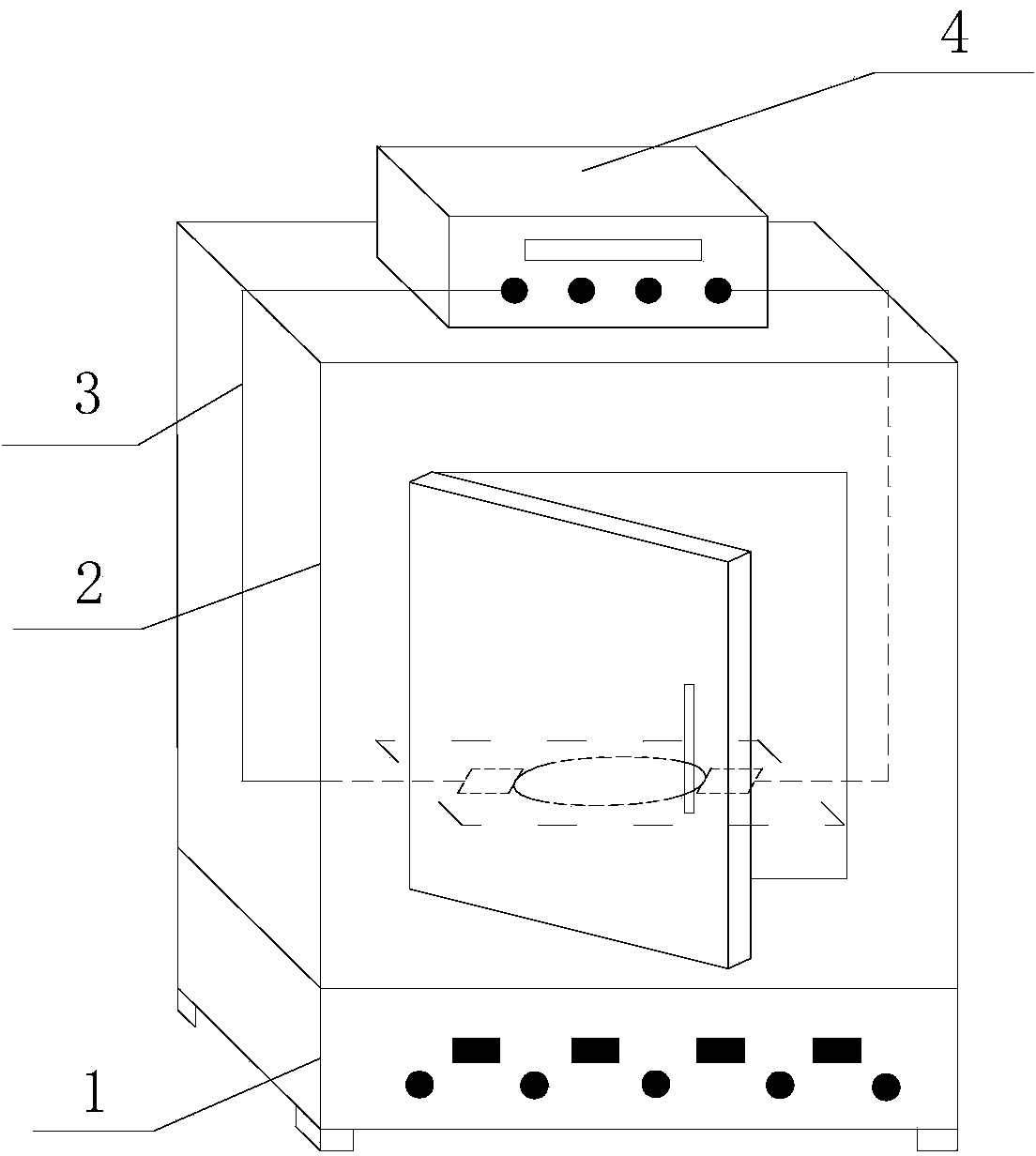

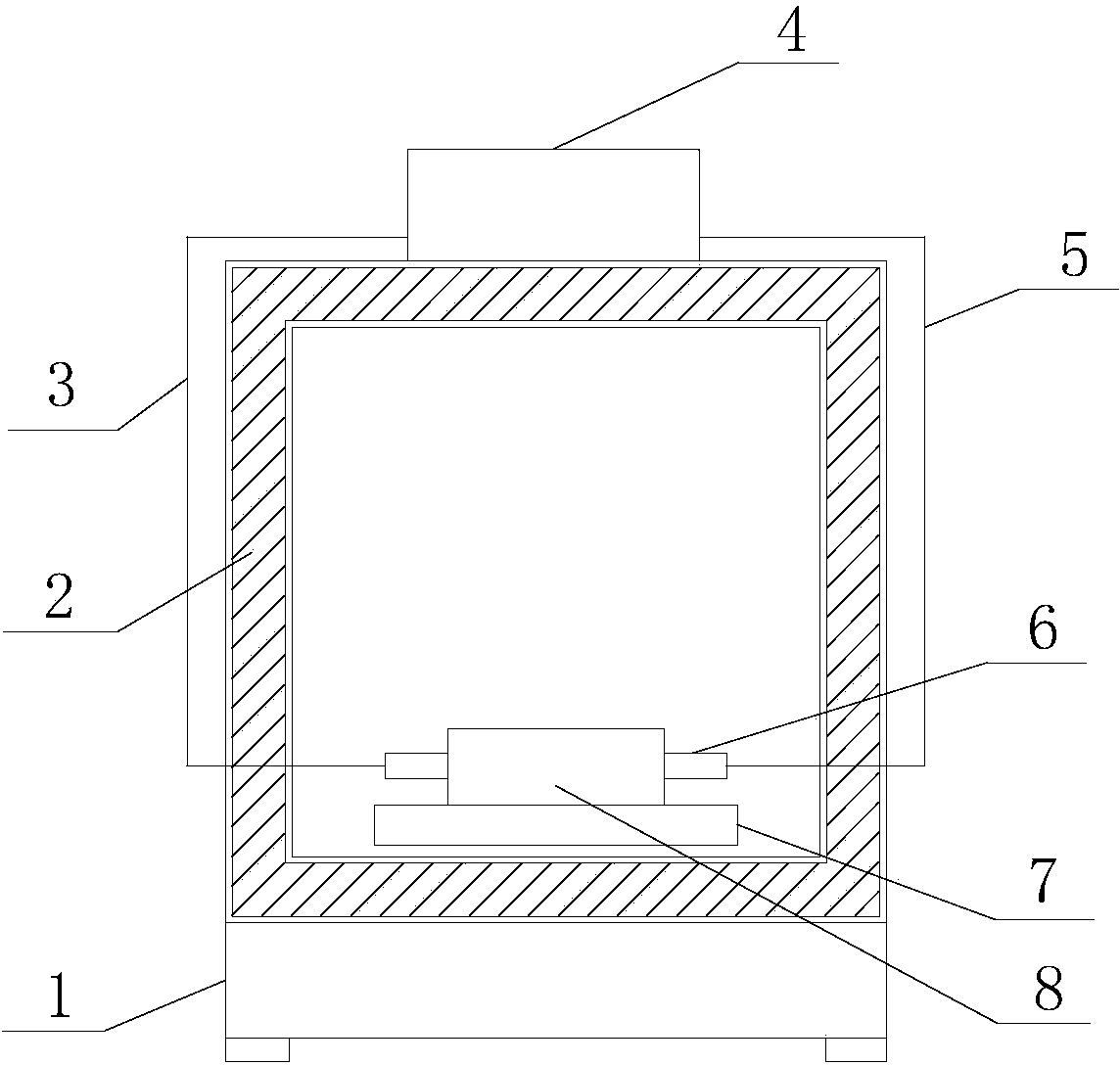

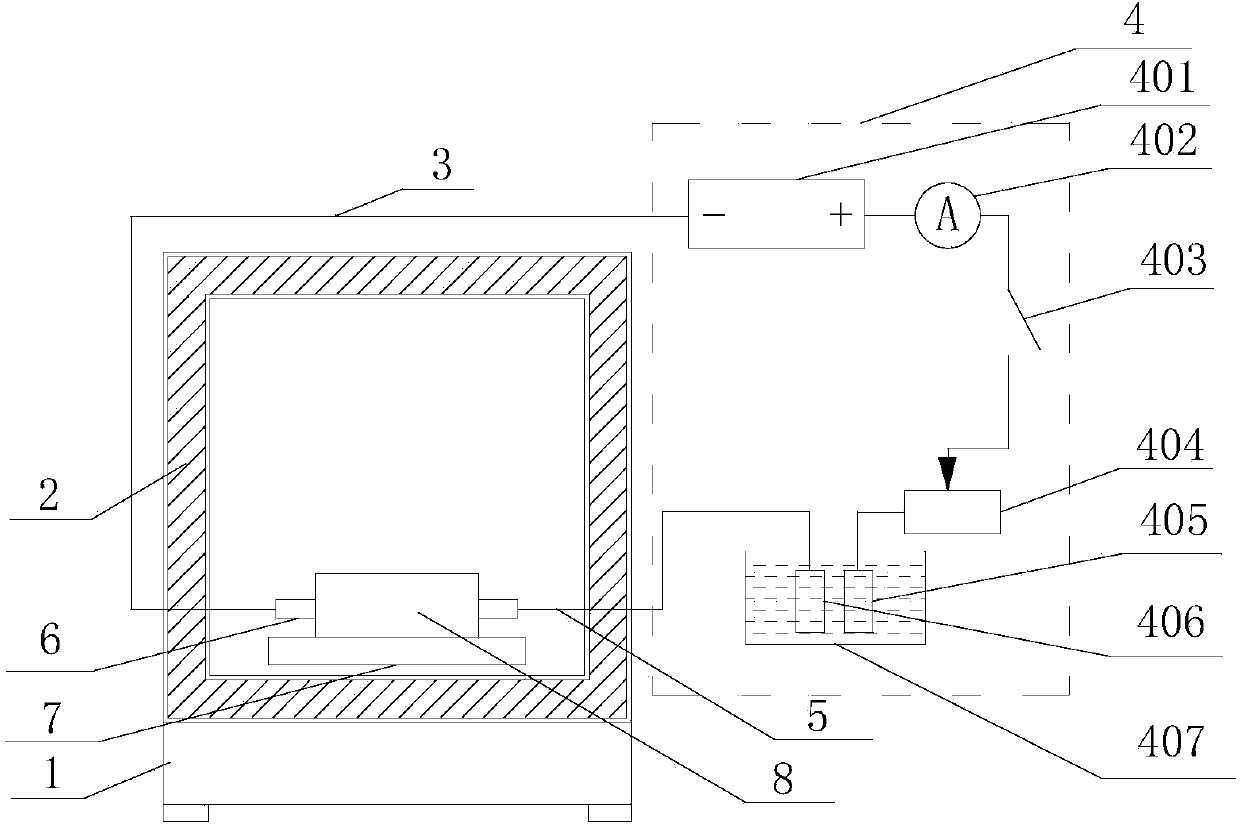

[0041] Clean out two clean areas of the spinneret to be cleaned, then place it on the stage in the hearth of the muffle furnace, connect it to the cathode wire and anode in the muffle furnace through copper metal clips Connect, the pinch point of the metal clip is in two clean areas, choose two dry batteries, the power supply voltage is 3V, close the switch, after the power circuit is connected, adjust the sliding rheostat to make the current display number 30mA; then, as figure 1 As shown, set the temperature control part (1) of the muffle furnace, set the calcination temperature of the muffle furnace to 550°C, and the calcination time to 20h, and perform calcination cleaning.

[0042] The corrosion of the spinneret after being calcined and cleaned by this method is greatly reduced, which does not affect the reuse.

Embodiment 2

[0044] Clean out two clean areas of the spinneret to be cleaned, then place it on the stage in the hearth of the muffle furnace, connect it to the cathode wire and anode in the muffle furnace through copper metal clips Connect, the pinch point of the metal clip is in two clean areas, choose a dry battery, then the power supply voltage is 1.5V, close the switch, after the power circuit is connected, adjust the sliding rheostat to make the current display 10mA; then, as figure 1 As shown, set the temperature control part (1) of the muffle furnace, set the calcination temperature of the muffle furnace to 450°C, and the calcination time to 10h, and perform calcination cleaning.

[0045] The corrosion of the spinneret after being calcined and cleaned by this method is greatly reduced, which does not affect the reuse.

Embodiment 3

[0047] Clean out two clean areas of the spinneret to be cleaned, then place it on the stage in the hearth of the muffle furnace, connect it to the cathode wire and anode in the muffle furnace through copper metal clips Connect, the pinch point of the metal clip is in two clean areas, choose a battery, the power supply voltage is 2V, close the switch, after the power circuit is connected, adjust the sliding rheostat to make the current display 20mA; then, as figure 1 As shown, set the temperature control part (1) of the muffle furnace, set the calcination temperature of the muffle furnace to 550°C, and set the calcination time to 15h to perform calcination cleaning.

[0048] The corrosion of the spinneret after being calcined and cleaned by this method is greatly reduced, which does not affect the reuse.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com