Stannic oxide membrane electrode material for dye-sensitized solar cell and preparing method thereof

A thin-film electrode and tin oxide technology, applied in photosensitive equipment, electrolytic capacitors, circuits, etc., can solve the problems of limited photoelectric conversion efficiency, insufficient sunlight utilization rate, and low dye adsorption, achieve high light scattering ability, and improve photoelectric conversion Efficiency, the effect of increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

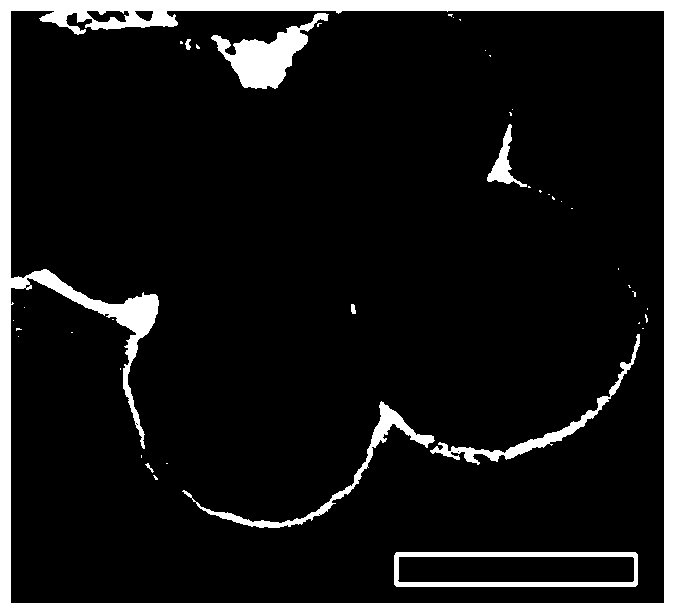

[0026] The sucrose aqueous solution with a concentration of 1.5M was hydrothermally treated in an autoclave at 200°C for 135min; after natural cooling, the filtered carbon spheres were washed with water and ethanol several times, and dried in an oven at 80°C for 12h. The particle size of carbon spheres is 3 μm. Disperse 0.6 g of carbon spheres into a 0.05 M NaOH solution and stir for 1 h, then wash with distilled water and dry.

[0027]The carbon spheres treated with alkaline solution were evenly dispersed in 30mL of SnCl with a concentration of 2M 4 In the aqueous solution, stir for 4 hours, filter with suction, wash with deionized water 3 times, put it in an oven at 80°C for 12 hours, put the obtained solid powder in a muffle furnace, and raise the temperature to 500°C at a rate of 1°C / min. Calcined at constant temperature for 1h. After natural cooling, SnO with the outermost two shells adjacent 2 Five-shell hollow sphere;

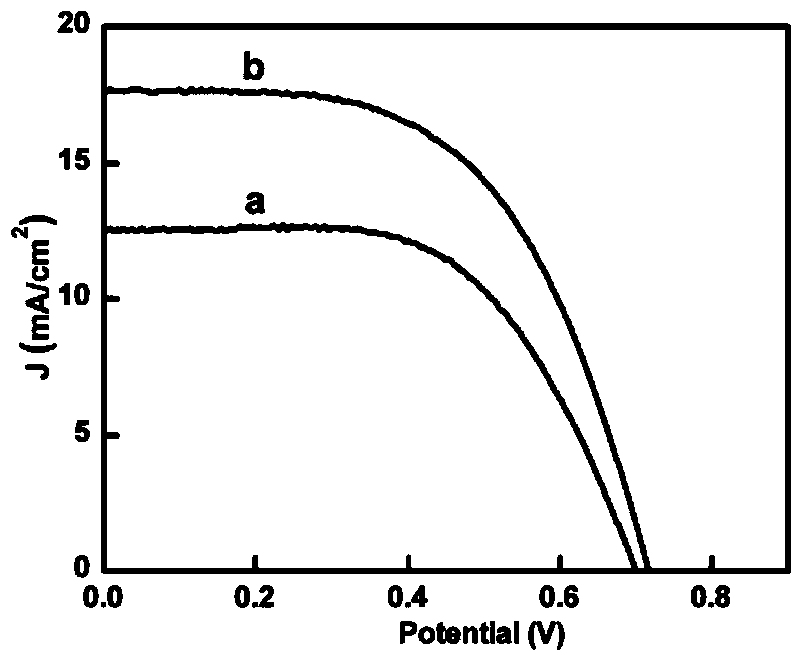

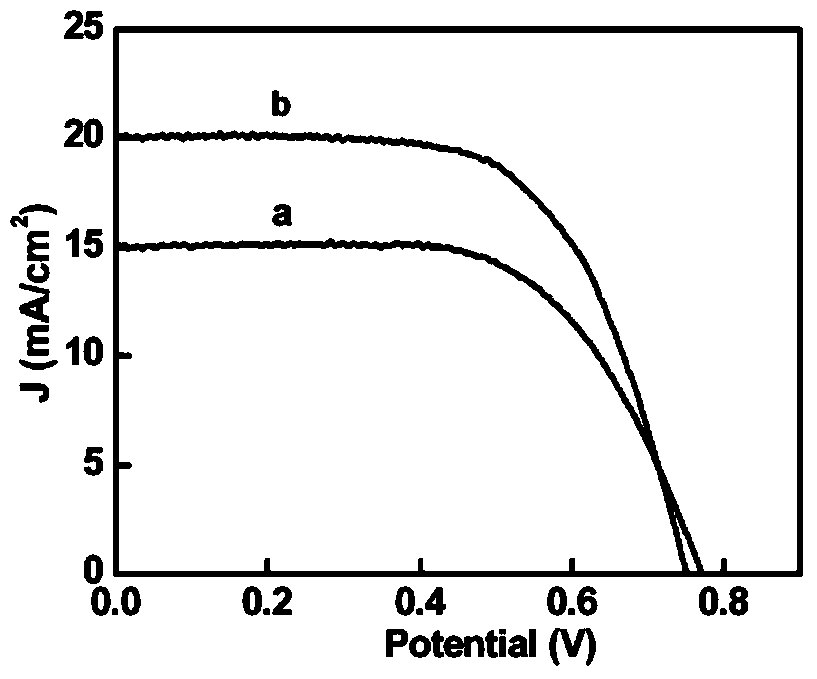

[0028] The prepared SnO adjacent to the outerm...

Embodiment 2

[0031] The sucrose aqueous solution with a concentration of 1.5M was hydrothermally treated in an autoclave at 200°C for 135min; after natural cooling, the filtered carbon spheres were washed with water and ethanol several times, and dried in an oven at 80°C for 12h. The particle size of carbon spheres is 3 μm. Disperse 0.6 g of carbon spheres into a 0.05 M NaOH solution and stir for 1 h, then wash with distilled water and dry.

[0032] The carbon spheres treated with alkaline solution were evenly dispersed in 30mL of SnCl with a concentration of 1.5M 4 In the aqueous solution, stir for 4 hours, filter with suction, wash with deionized water 3 times, put it in an oven at 80°C for 12 hours, put the obtained solid powder in a muffle furnace, and raise the temperature to 500°C at a rate of 1°C / min. Calcined at constant temperature for 1h. After natural cooling, SnO with the outermost two shells adjacent 2 four-shell hollow sphere;

[0033] The prepared SnO adjacent to the out...

Embodiment 3

[0035] The sucrose aqueous solution with a concentration of 1.5M was hydrothermally treated in an autoclave at 200°C for 135min; after natural cooling, the filtered carbon spheres were washed with water and ethanol several times, and dried in an oven at 80°C for 12h. The particle size of carbon spheres is 3 μm. Disperse 0.6 g of carbon spheres into a 0.06 M NaOH solution and stir for 2 h, then wash with distilled water and dry.

[0036] The carbon spheres treated with alkaline solution were evenly dispersed in 30mL of SnCl with a concentration of 1.0M 4 In the aqueous solution, stir for 4 hours, filter with suction, wash with deionized water 3 times, put it in an oven at 80°C for 12 hours, put the obtained solid powder in a muffle furnace, and raise the temperature to 500°C at a rate of 1°C / min. Calcined at constant temperature for 1h. After natural cooling, SnO with the outermost two shells adjacent 2 Three-shell hollow sphere;

[0037] The prepared SnO adjacent to the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com