Sweet buckwheat noodle formula and preparation method

A technology for sweet buckwheat and noodles, which is applied to food preparation, bacteria used in food preparation, food processing and other directions, can solve the problems of low nutritional value, poor processing performance, poor taste of buckwheat flour, etc., and achieves simple production process and production cost. The effect of low and easy production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

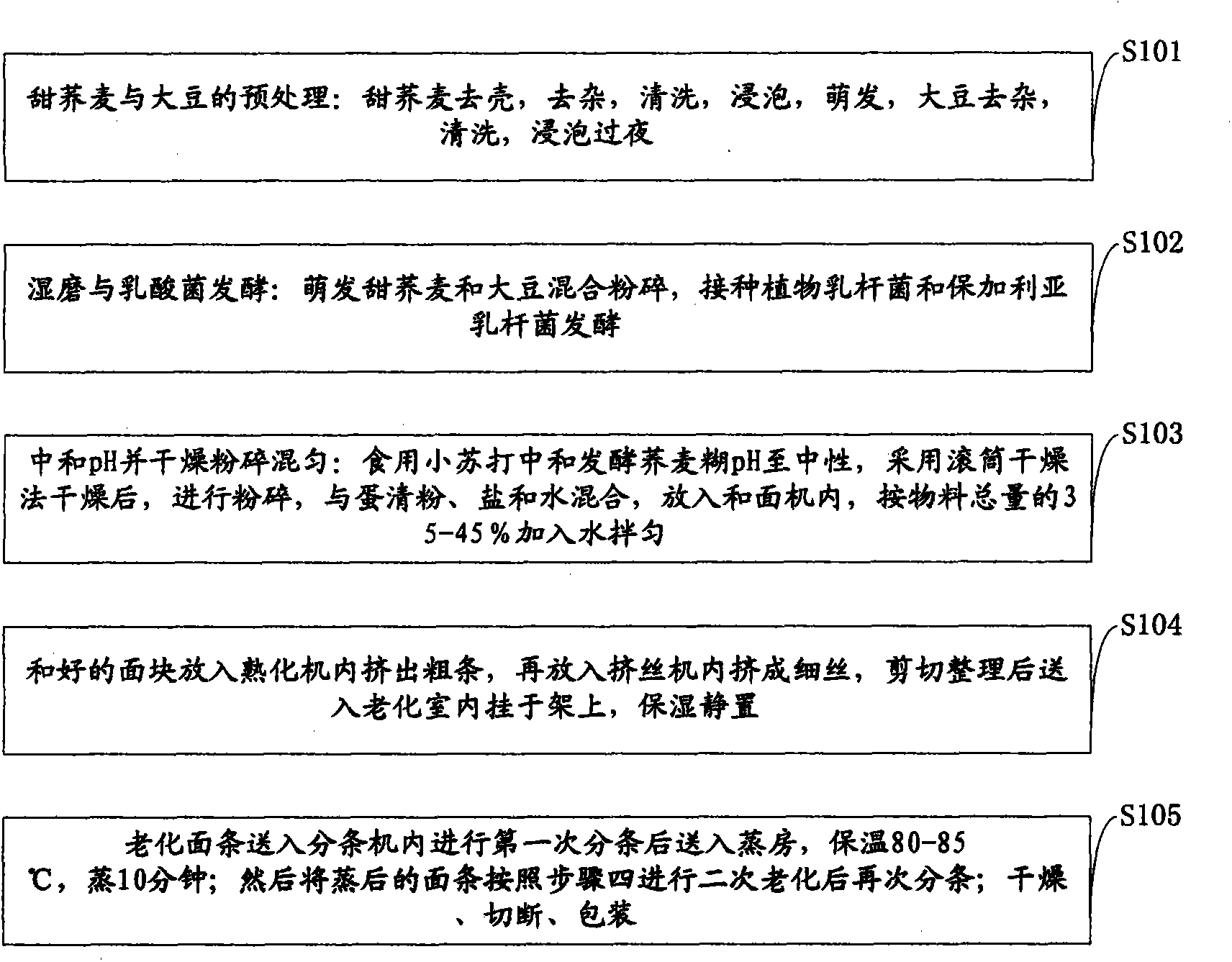

[0026] like figure 1 As shown, another object of the embodiments of the present invention is to provide a method for preparing sweet buckwheat noodles, which comprises the following steps:

[0027] Step 1. Pretreatment of sweet buckwheat and soybeans: shelling of sweet buckwheat, removing impurities, washing, soaking, germination, removing impurities of soybeans, washing, soaking overnight;

[0028] Step 2, wet milling and lactic acid bacteria fermentation: germinated sweet buckwheat and soybeans are mixed and ground, inoculated with Lactobacillus plantarum and Lactobacillus bulgaricus for fermentation;

[0029] Step 3. Neutralize the pH, dry and pulverize and mix well: use baking soda to neutralize the pH of the fermented buckwheat paste to neutral, use the drum drying method to dry, then pulverize, mix with egg white powder, salt and water, and put it into the dough mixer , add water according to 35-45% of the total amount of materials and mix well;

[0030] Step 4. Put th...

Embodiment 1

[0037] Example 1: Sweet Buckwheat Fresh Noodles

[0038] 1. Activate and subculture Lactobacillus plantarum and Lactobacillus bulgaricus to obtain a mother starter, and mix the two at a ratio of 2:1 to prepare a working starter;

[0039] 2. Remove impurities from soybeans, wash them, and soak them overnight;

[0040] 3. Peel the sweet buckwheat, remove impurities, soak and germinate, the temperature is 30°C, the humidity is 70%, the time is 45h, and the soybeans are mixed according to the weight of 0.1-0.5% of the germinated sweet buckwheat;

[0041] 4. Refining the mixture obtained in step 3, inoculating the starter prepared in step 1 for fermentation, adding an appropriate amount of edible baking soda to neutralize the pH to neutral, drying and pulverizing;

[0042] 5. Add 1-3% egg white powder, 0.3-0.8% gluten powder, and 1% salt, mix well, knead the dough, shred it, cut it, and pack it.

Embodiment 2

[0043] Embodiment 2, sweet buckwheat vermicelli

[0044] 1. Lactobacillus plantarum and Lactobacillus bulgaricus are activated, added to make mother starter, and mixed 1:1 to make working starter;

[0045] 2. Remove impurities from soybeans, wash them, and soak them overnight;

[0046] 3. Peel the sweet buckwheat, remove impurities, soak and germinate, the temperature is 30°C, the humidity is 70%, the time is 50h, and the germinated sweet buckwheat and soybean are mixed according to the weight ratio of 90:1;

[0047] 6. Refining the mixture obtained in step 3, inoculating the starter prepared in step 1 for fermentation, adding edible baking soda to neutralize the pH to neutral, drying and pulverizing;

[0048] 4. Add 1-3% egg white powder, 0.2-0.6% compound phosphate, and 1% salt, mix well, knead the noodles and shred, cut and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com