Water-circulating floor-cleaning vehicle

A technology for washing a floor car and water circulation, applied in the field of cleaning equipment, can solve the problems of increasing the consumption of battery power, low level of sewage pollution, and increasing the volume of the floor washing car, so as to reduce the volume and weight, facilitate operators, The effect of low water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

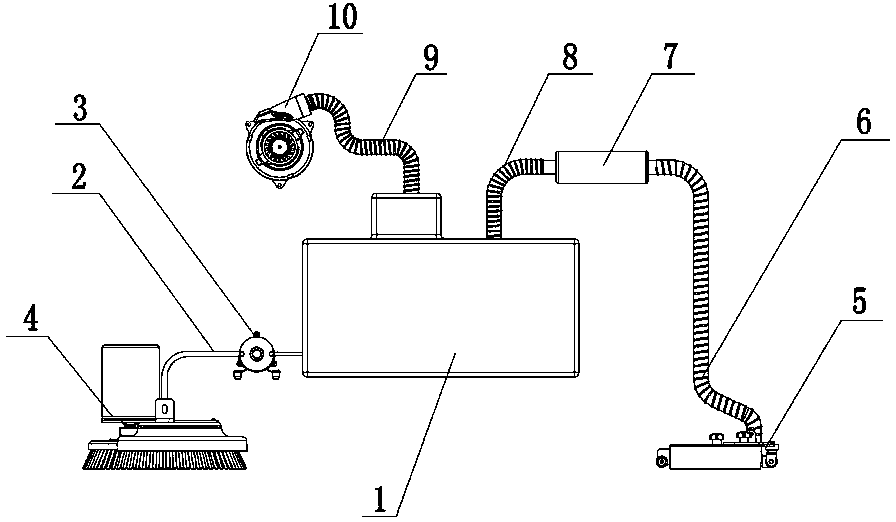

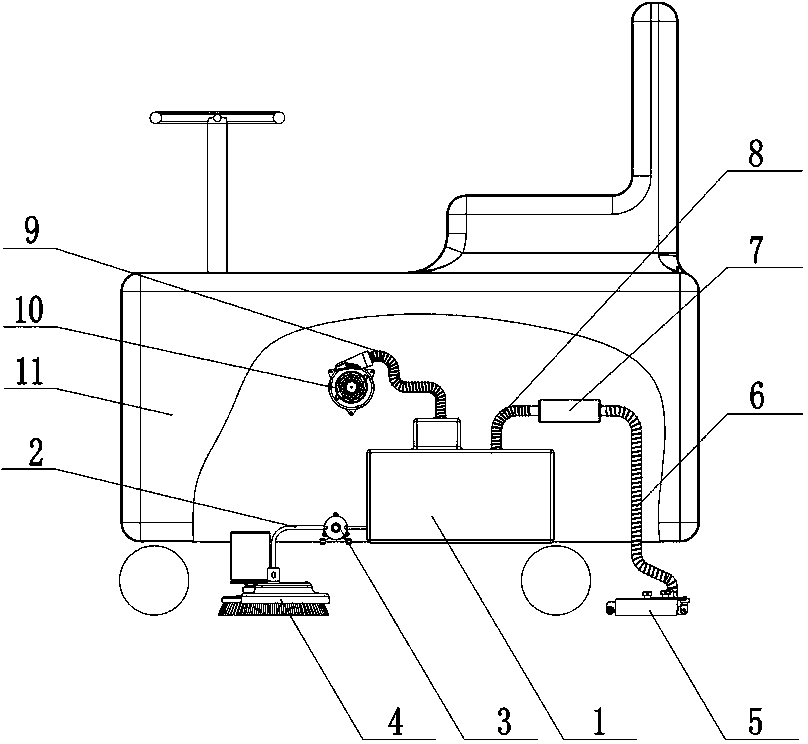

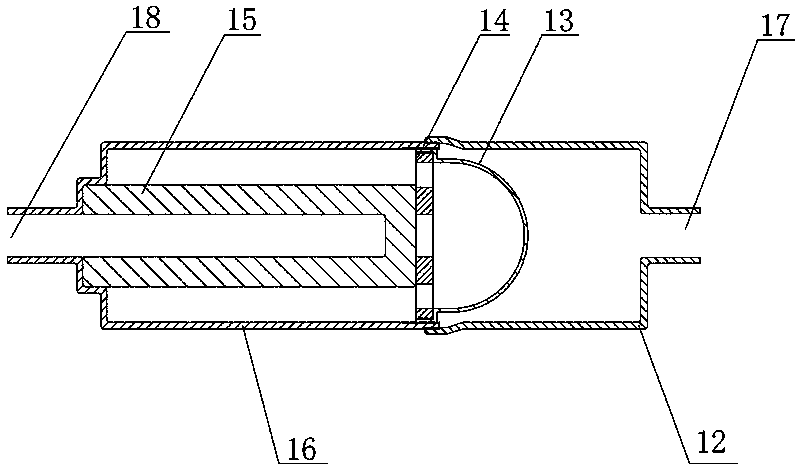

[0026] combine as figure 1 As shown, the water tank 1, the vacuum pump 10, the water pump 3 and the filter 7 are installed in the vehicle frame 11, and the electric brush plate 4 is installed under the front section of the vehicle frame in the forward direction, so that the surface of the brush plate can fully contact with the ground, and the same wiper 5 is installed under the rear section of the vehicle frame in the forward direction, so that the bottom of the wiper 5 can fully contact the ground, the electric brush plate 4 and the wiper 5 are aligned in the forward direction of the water circulation scrubber, and the air inlet of the vacuum pump 10 is aligned with the ground. The exhaust port of the water tank 1 is connected through the exhaust pipe 9; the water inlet of the water pump 3 is connected with the water supply port of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com