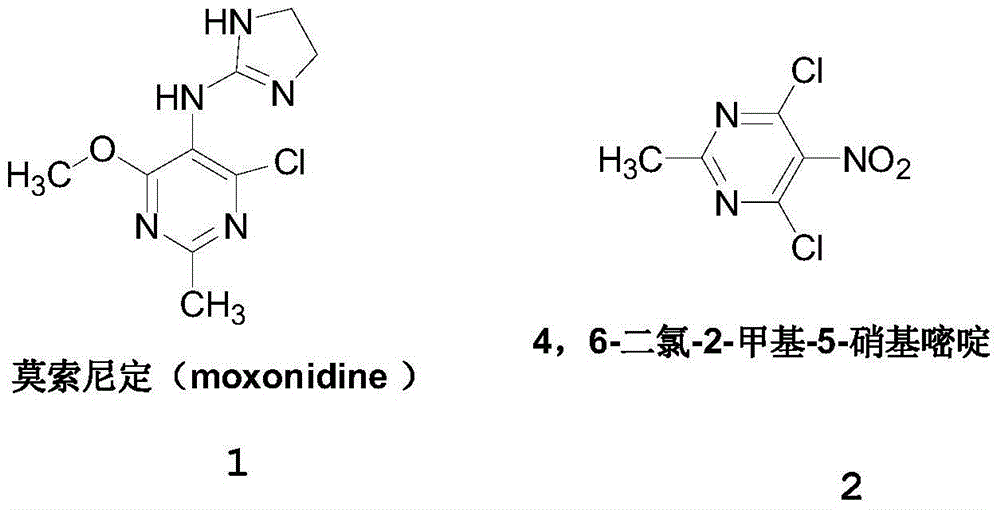

A kind of preparation method of 4,6-dichloro-2-methyl-5-nitropyrimidine

A technology of nitropyrimidine and methylpyrimidine, which is applied in the field of pharmaceutical chemistry, can solve the problems of ecological environment pollution and the production of highly toxic substances, and achieve the effect of strong operability and short technical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

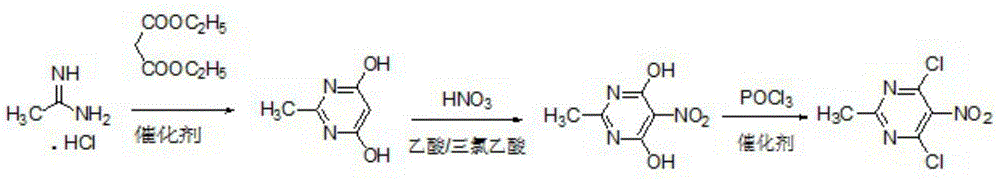

Method used

Image

Examples

example 1

[0025] Preparation of 4,6-Dihydroxy-2-methylpyrimidine

[0026] Add acetamidine hydrochloride (47.3 g, 0.50 mol), diethyl malonate (76.5 g, 0.52 mol) and methanol (200 ml) into a 1.0L reaction flask, and add 30% (mass fraction of solute) while stirring at room temperature Sodium methoxide-methanol solution (275.5 g, 1.53 mol), stirred and heated to reflux for 3 hours, followed by TLC. After the reaction is complete, cool, filter, wash with water and methanol, and then dissolve the filter cake in 350 ml of water. Adjust pH=2 with hydrochloric acid, white precipitate precipitates out, stand still, filter, wash with water, and dry to obtain 4,6-dihydroxy-2-methylpyrimidine (57.5g) as an off-white solid, with a yield of 91.2% (based on acetamidine hydrochloride meter),

[0027] M.p.338-345℃, 1 H NMR: (400Hz, DMSO-d 6 ), δ (ppm): 11.75 (s, 2H, -OH), 4.95 (s, 1H, CH-), 2.21 (s, 3H, CH 3 -).;

[0028] (1) Preparation of 4,6-dihydroxy-2-methyl-5-nitropyrimidine

[0029] Add the prepared 4,6...

example 2

[0035] Preparation of 4,6-Dihydroxy-2-methylpyrimidine

[0036] Add acetamidine hydrochloride (47.3 g, 0.50 mol), diethyl malonate (76.5 g, 0.52 mol) and ethanol (150 ml) into a 1.0L reaction flask, and add 20% (mass fraction of solute) while stirring at room temperature Sodium ethoxide-ethanol solution (476.0 g, 1.42 mol), stirred and heated under reflux for 4 hours, followed by TLC. After the reaction is complete, cool, filter, wash with water and methanol, then dissolve the filter cake in 450 ml of water, sulfuric acid Adjust pH=1, white precipitate precipitates out, stand still, filter, wash with water, and dry to obtain off-white solid 4,6-dihydroxy-2-methylpyrimidine (56.6g), the yield is 89.8% (calculated as acetamidine hydrochloride) ).

[0037] (1) Preparation of 4,6-dihydroxy-2-methyl-5-nitropyrimidine

[0038] Add the prepared 4,6-dihydroxy-2-methylpyrimidine (12.6g, 0.10mol), trichloroacetic acid (12.3g, 0.075mol), and acetic acid (102ml, 1.80mol) prepared above into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com