Functional isotactic polypropylene and preparation method thereof

An isotactic polypropylene and functional technology, applied in the field of polypropylene, can solve problems such as low melting temperature and irregular molecular chain structure, and achieve the effects of good tolerance, good copolymerization ability and high regioselectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method for the functional isotactic polypropylene, comprising:

[0041] Under the action of a catalyst and a cocatalyst, propylene and a halogenated olefin having a structure of formula (III) are polymerized in an inert solvent to obtain functional isotactic polypropylene; the catalyst is a dimethylformaldehyde having a structure of formula (IV) Basepyridylamine hafnium complex, the cocatalyst is triphenylcarbon tetrakis (pentafluorophenyl) borate;

[0042]

[0043] Wherein, x is a halogen;

[0044] y is 1-16.

[0045] R 1 , R 2 with R 3 each independently selected from hydrogen or different alkyl groups of C1-C10.

[0046] In the process of preparing functional isotactic polypropylene, the catalyst is a hafnium lutidine amine complex and the co-catalyst is triphenylcarbon tetrakis (pentafluorophenyl) borate catalyst system to catalyze the reaction of propylene with the formula ( Ⅲ) Structure olefins, that is, t...

Embodiment 1

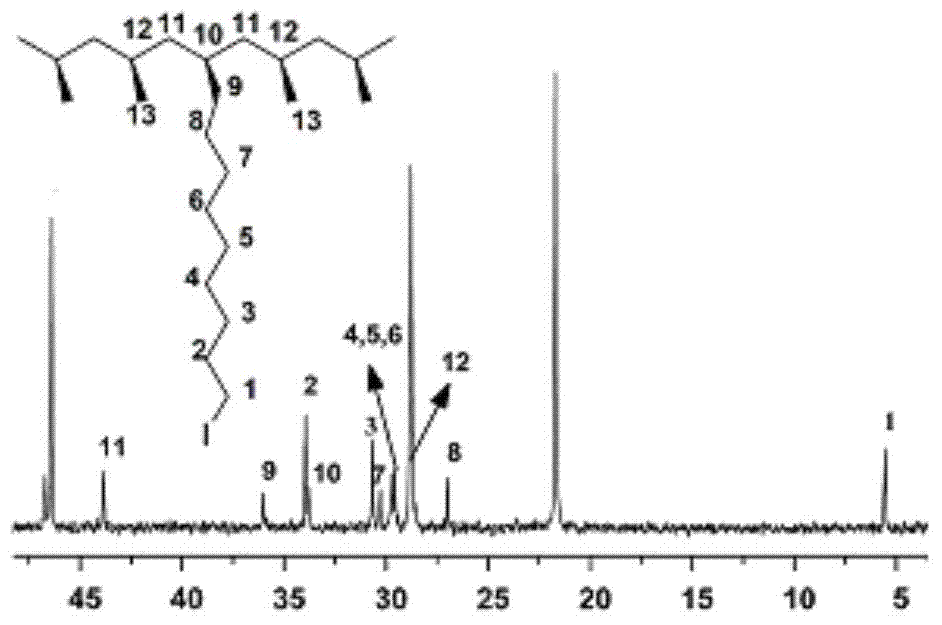

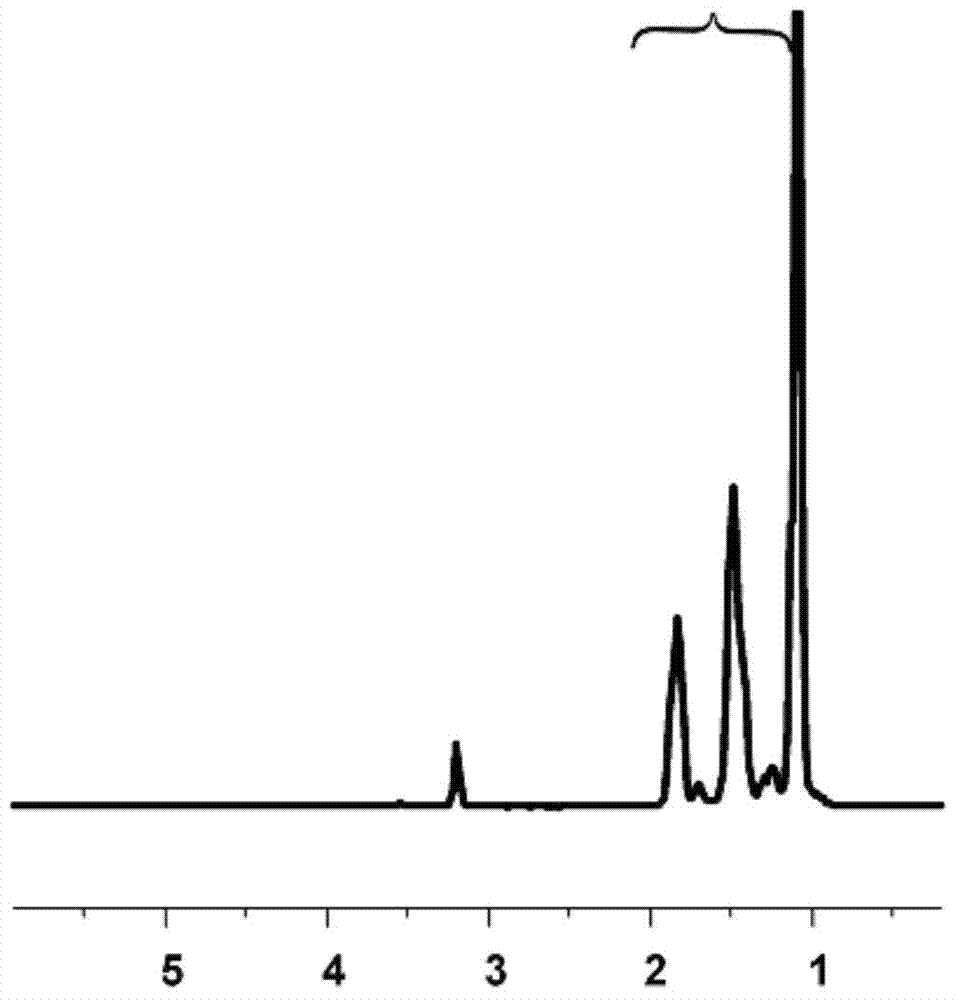

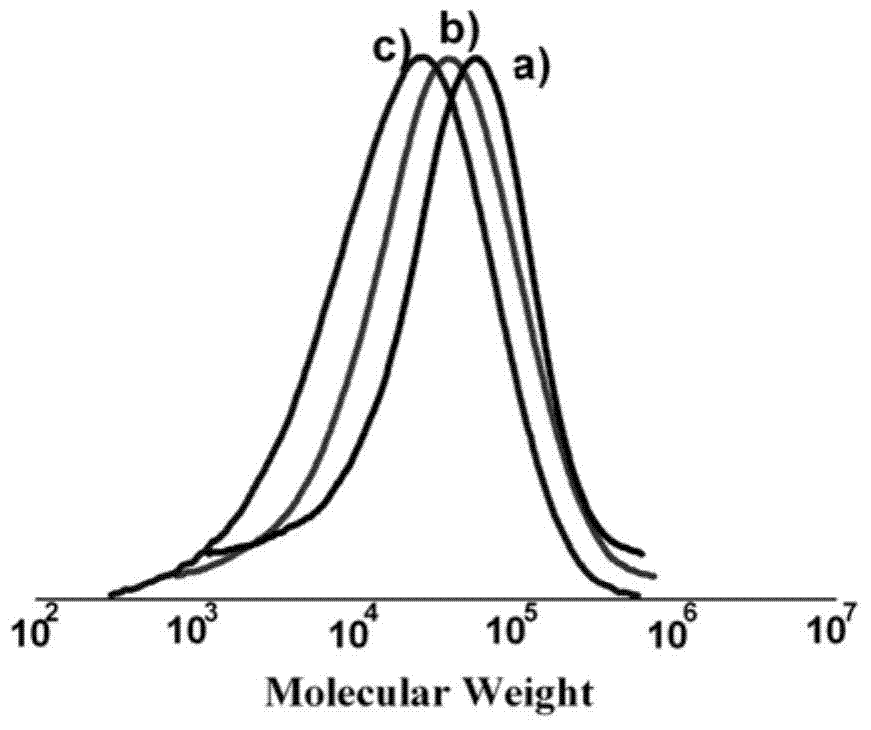

[0060] Under propylene atmosphere, 30mL anhydrous toluene, 7.4mmol11-iodo-1-undecene and 1.0mL cleaning agent triisobutylaluminum (Al( i Bu) 3 ) in toluene solution (0.5M), stirred at 25°C for 10min, then added 5μmol of catalyst dimethylpyridinium hafnium complex (R 1 , R 2 with R 3 Both are isopropyl) and 10 μmol cocatalyst triphenylcarbon tetrakis (pentafluorophenyl) borate ([Ph 3 C][B(C 6 f 5 ) 4 ])) mixture to initiate the reaction, the total solution volume is 40mL, continue to pass through propylene and keep the pressure of propylene at 1 atmosphere, after 10 minutes of reaction, pour the reaction solution into the ethanol solution containing 10% (V / V) hydrochloric acid, and a large amount of White polymer; the product obtained by filtration was washed 3 times with acetone and then dried in a vacuum oven at 60°C for 24 hours, and weighed to obtain 0.32g of polymer. The catalytic activity of the polymer was 3.80×10 5 g / mol Hf h, the relative weight average molecul...

Embodiment 2

[0062] Under a propylene atmosphere, 30 mL of anhydrous toluene, 3.7 mmol of 11-iodo-1-undecene and 1.0 mL of Al( i Bu) 3 Toluene solution (0.5M), after stirring at 25°C for 10min, add 5μmol of catalyst dimethylpyridinium hafnium complex (R 1 , R 2 with R 3 Both are isopropyl) and 10 μmol cocatalyst triphenylcarbon tetrakis (pentafluorophenyl) borate ([Ph 3 C][B(C 6 f 5 ) 4 ])) mixture to initiate the reaction, the total solution volume is 40mL, continue to pass through propylene and keep the pressure of propylene at 1 atmosphere, after 10 minutes of reaction, pour the reaction solution into the ethanol solution containing 10% (V / V) hydrochloric acid, and a large amount of White polymer; the product obtained by filtration was washed 3 times with acetone and then dried in a vacuum oven at 60°C for 24 hours, and weighed to obtain 0.5g of polymer. The catalytic activity of the polymer was 6.00×10 5 g / mol Hf h, the relative weight average molecular weight is 130kg / mol, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com