Lubricating grease containing modified silica component and preparation method of lubricating grease

A technology of lubricating grease and lithium-based grease, applied in lubricating composition, dyeing organosilicon compound treatment, petroleum industry, etc. Inconvenience, reducing the service life of grease, etc., to achieve good colloidal stability, small water loss, and small quality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] SiO 2 Surface modification and its containing modified SiO 2 The preparation method of lubricating grease, its preparation method step is as follows:

[0048] 1), SiO2 2 When treating the particle surface with a silane modifier, the SiO 2 Uniformly dispersed in synthetic oil PAO, temperature controlled at 130°C to 160°C, silane modifier and SiO 2 The weight ratio of the particles is 1:20-1:10 (in Example 5, in order to verify the effect of the silane modifier, a blank comparison test was specially done); add the hydrolyzed silane modifier, and react 5-8 Hour.

[0049] 2) SiO 2 After the particles are surface treated, the temperature drops below 100°C, add 12-hydroxystearic acid, stearic acid and base oil to dissolve the 12-hydroxystearic acid, stearic acid, and keep the temperature at 85°C-95°C, Add lithium hydroxide solution to start saponification, and the saponification time is controlled at 2-4 hours.

[0050] 3) After the saponification is completed, stir an...

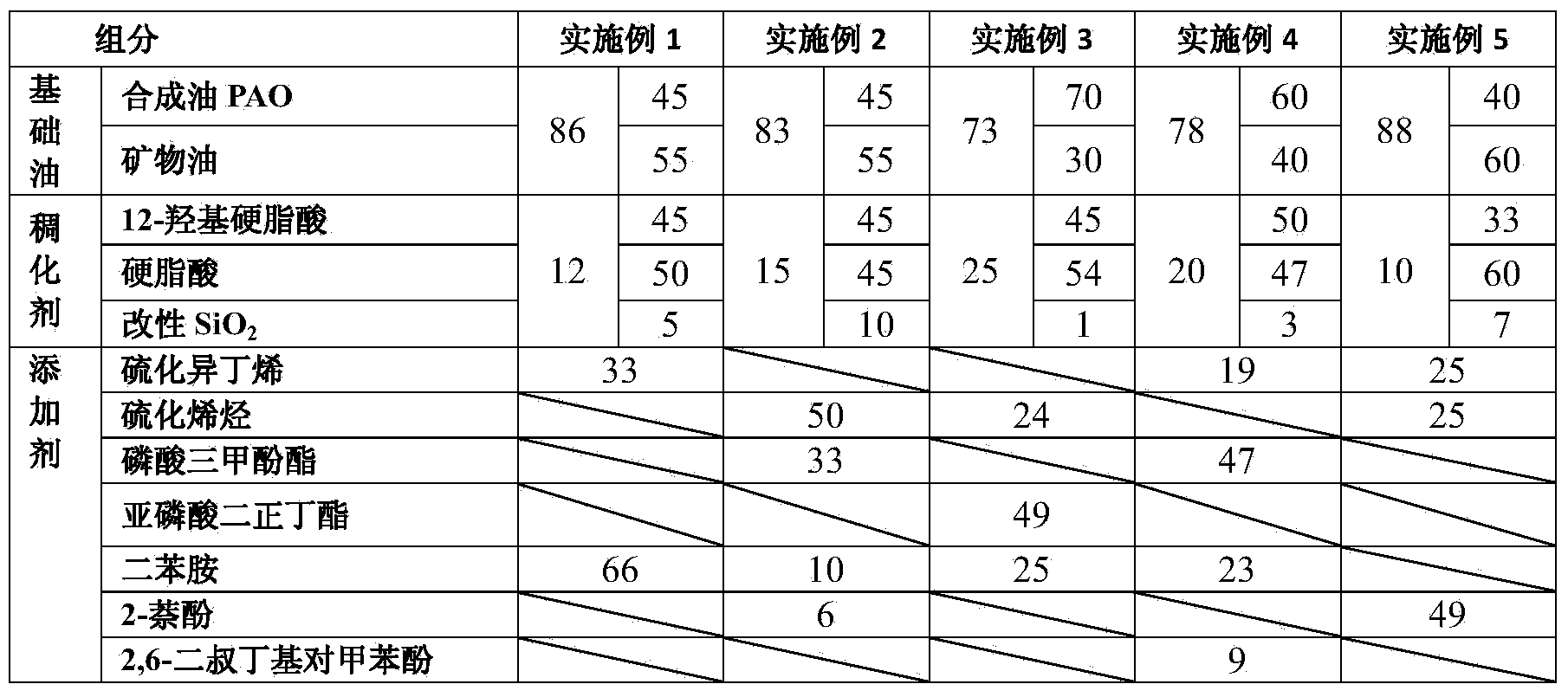

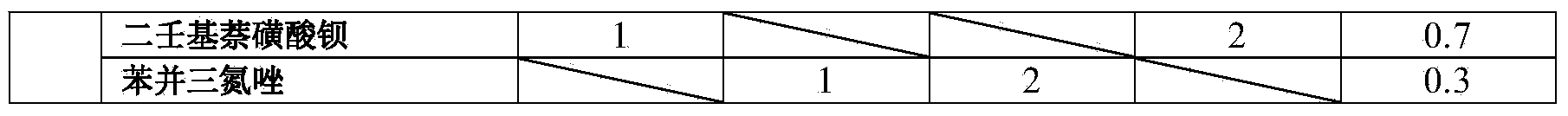

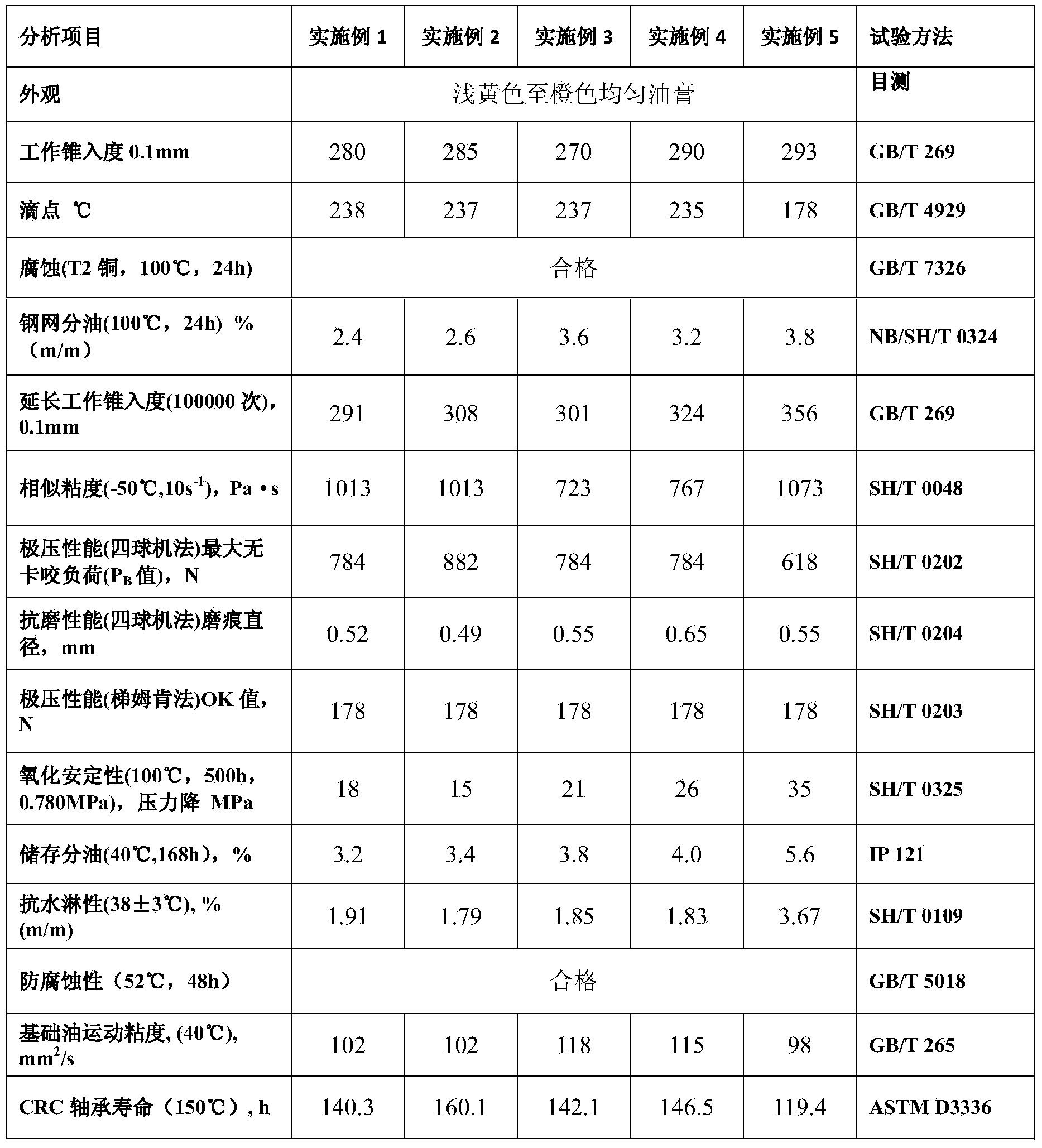

Embodiment 1

[0053] 11.4g of SiO 2 Evenly dispersed in 300g of synthetic oil PAO, the temperature was controlled at 135°C, 0.6g of hydrolyzed silane modifier was added, and reacted for 5 hours. Lower the temperature to 90°C, add 108g of 12-hydroxystearic acid, 120g of stearic acid, and 846g of mineral oil to fully dissolve the 12-hydroxystearic acid and stearic acid, keep the temperature at 85°C, and add lithium hydroxide containing 36g of aqueous solution begins to saponify, and the saponification time is controlled within 3 hours. After the saponification is completed, stir and heat to 190°C, add 574g of synthetic oil for rapid cooling, continue stirring, and add additives such as 13.2g of sulfurized isobutylene, 26.4g of diphenylamine, dinonyl 0.4 g of barium naphthalene sulfonate, after being evenly stirred, after being homogenized three times by a three-roll machine, the finished product is filled.

[0054] Contains modified SiO 2 The weight percent of each component of the lubricat...

Embodiment 2

[0063] 27g of SiO 2 Disperse in 400g of synthetic oil PAO, control the temperature at 160°C, add 3g of hydrolyzed silane modifier, react for 8 hours and lower the temperature to 90°C, add 135g of 12-hydroxystearic acid, 135g of stearic acid , mineral oil 660g, fully dissolve 12-hydroxystearic acid and stearic acid, keep the temperature at 95°C, add an aqueous solution containing 42g of lithium hydroxide to start saponification, saponification time is controlled at 4 hours, after saponification is completed, stir and heat to 210°C, add 347g synthetic oil and 253g mineral oil for rapid cooling, keep stirring, add additives below 90°C 20g sulfurized olefin, 13.2g tricresyl phosphate, 4g diphenylamine, 2.4g 2-naphthol, 0.4 benzotriazole g. After stirring evenly, after three times of homogenization treatment by a three-roller machine, the finished product is filled.

[0064] Contains modified SiO 2 The weight percent of each component of the lubricating grease of component is:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com