Thermoacoustic driven stirling engine

A Stirling engine and thermoacoustic technology, applied in the field of engines and Stirling engines, can solve problems such as reducing engine reliability and shortening engine service life, and achieve the effects of reducing failure sources, high conversion efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

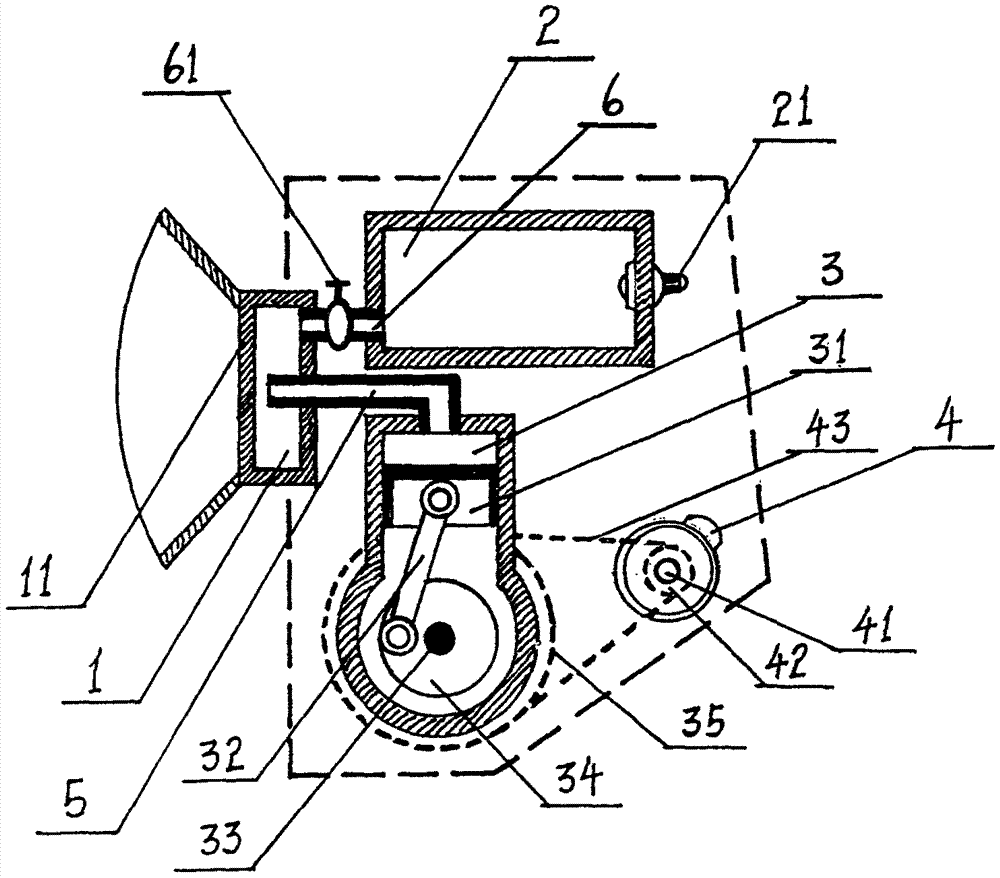

[0015] figure 1 The shown "a thermoacoustic-driven Stirling engine" is composed of four core components: a heat chamber 1, a high-pressure gas storage cylinder 2, a power cylinder 3, and a motor 4 (a motor integrating electric and power generation functions). , the power cylinder 3 is communicated with the heat chamber 1 by setting the air passage 5, and the heat chamber 1 is communicated with the high-pressure gas cylinder 2 by setting an upper air passage 6, and the middle part of the upper air passage 6 is provided with an air valve 61. Except for the motor 4, the whole structure of the above components is fully enclosed and isolated from the outside world, and its interior is filled with high-pressure working gas, which is helium.

[0016] Described power cylinder 3 is made up of its internal power piston 31, connecting rod 32, flywheel 34 and the engine shaft 33 supporting take-off wheel 34, and the other end of engine shaft 33 is also provided with large belt pulley 35. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com