Flexible LED (light-emitting diode) light source filament

A LED light source, flexible technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of limited irradiation angle, large impact on life, accelerated light decay, etc., achieve less heat generation, improve light, and reduce heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

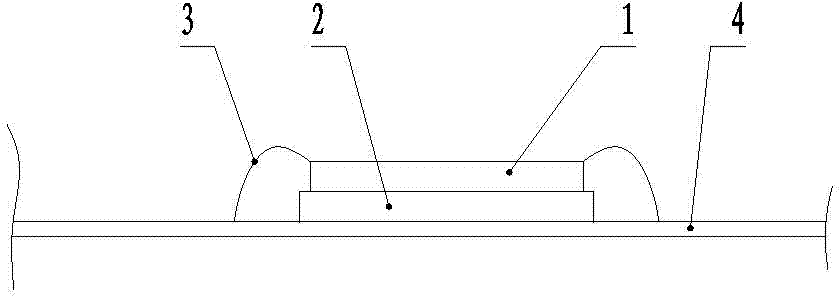

Embodiment 1

[0020] Example 1, such as figure 2 As shown, a flexible LED light source filament is improved on the basis of the existing LED light source. Through holes are made on the substrate for fixing the LED chip, and the LED chip is put into the hole to realize light emission from both sides. Specifically: P-N junction 1 and sapphire 2 are packaged together to form a single LED chip, the single LED chip is fixed on the substrate 4 by a mixture of phosphor powder and epoxy resin, and the two ends of the P-N junction are connected to the substrate 4 through gold wire 3 For electrical connection, the distance between the two ends of the P-N junction and the substrate 4 is also smaller than the existing distance, which can save the amount of gold wire 3, and the substrate 4 is designed with a fixing hole for fixing a single LED chip that can hold the LED chip , the fixing hole is a two-stage hole with a large upper part and a smaller one at the lower part. The large hole 43 is a counter...

Embodiment 2

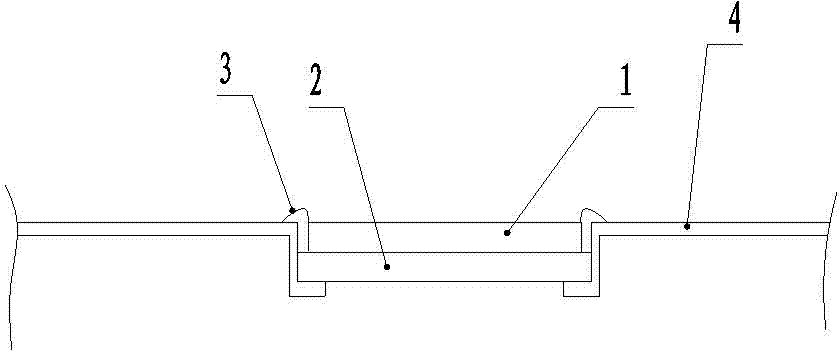

[0021] Example 2, such as image 3 , 4 As shown, it is improved on the basis of implementation 1. The substrate 4 is a copper plate with a thickness of 0.01-1mm and a width of 0.08-5mm. The surface is plated with silver, and the surface is etched with a conductive groove 41. It coincides with the center line of the fixing hole of the LED chip, and a plurality of fixing holes are evenly arranged, and each fixing hole is equipped with an LED chip, which can be cut according to the required brightness during use, and different numbers of LED chips can be selected. The inner diameter of the small hole 42 is smaller than the outer diameter of the P-N junction 1 in the LED chip. The P-N junction 1 of a single LED chip is downward, and the sapphire 2 is fixed in the fixing hole upward. The positive and negative poles of the P-N junction 1 are connected to the conductive groove 41. The conductive groove 41 is electrically connected.

Embodiment 3

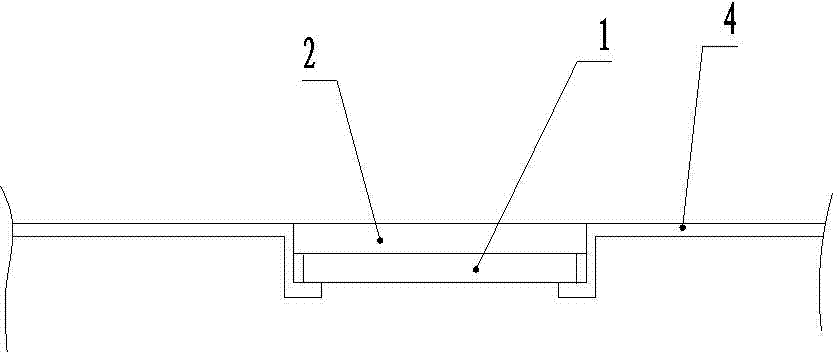

[0022] Embodiment 3, on the basis of implementation 2, a transparent plate with a thickness of 0.01-1mm is selected as the substrate 4, the surface is shaped on a long groove, and a conductive sheet is fixed in the groove to form a conductive groove 41, so that the substrate does not block the light emission of the LED chip. , can maximize the light efficiency. All the other unmentioned parts are the same as the above example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com