HCl recovery technique

A process and gas technology, which is applied in the field of recycling process in industrial production, can solve the problems of high energy consumption and large investment in equipment, and achieve the effects of wide application, reduced energy consumption, and saving equipment investment and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

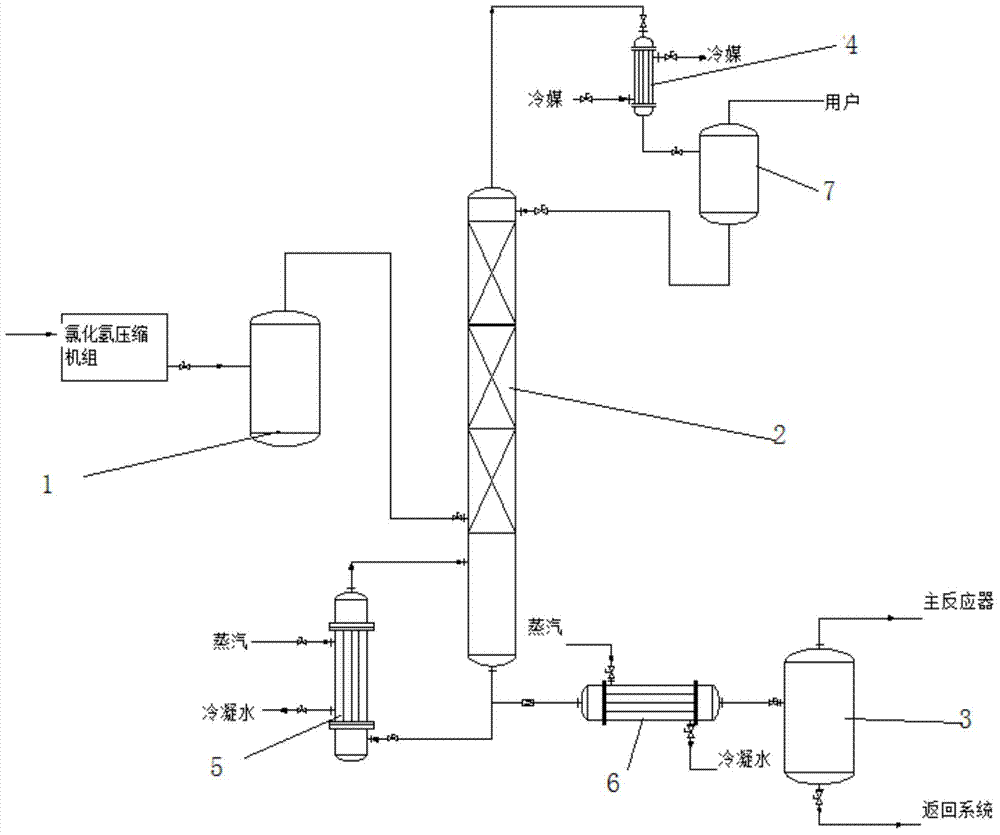

Image

Examples

Embodiment 1

[0017] HCl mixed gas enters the compressor, and after three-stage compression, the pressure reaches 1.6MPa, and then it is sent to the HCL rectification tower after passing through the buffer tank, the feed rate is 3000Kg / h, and the temperature is 40°C. The reboiler at the bottom of the tower is heated to about 60°C with steam, and the output at the bottom of the tower is 490kg / h. The HCl gas is produced at the top of the tower, and the HCl gas produced at the top of the tower is condensed through the top condenser 4, the condensation temperature is -17°C, the output is 2510kg / h, and the cooling capacity consumption of the HCl pressurized rectification production process is 0.09MKal / h, heat consumption is 0.1MKal / h.

[0018] When using the original process for recovery, the cooling energy consumption of the HCl absorption and desorption process is 1.0MKal / h, and the heat consumption is 1.7MKal / h.

[0019] Compared with the recovery of the original process, the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com