Method for continuously producing feed-grade dibasic calcium phosphate

A calcium hydrogen phosphate, feed-grade technology, applied in the field of phosphorus chemical industry, can solve problems such as low economic added value, increased investment, unstable product quality, etc., and achieve compact production process connection, improved production efficiency, and good appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

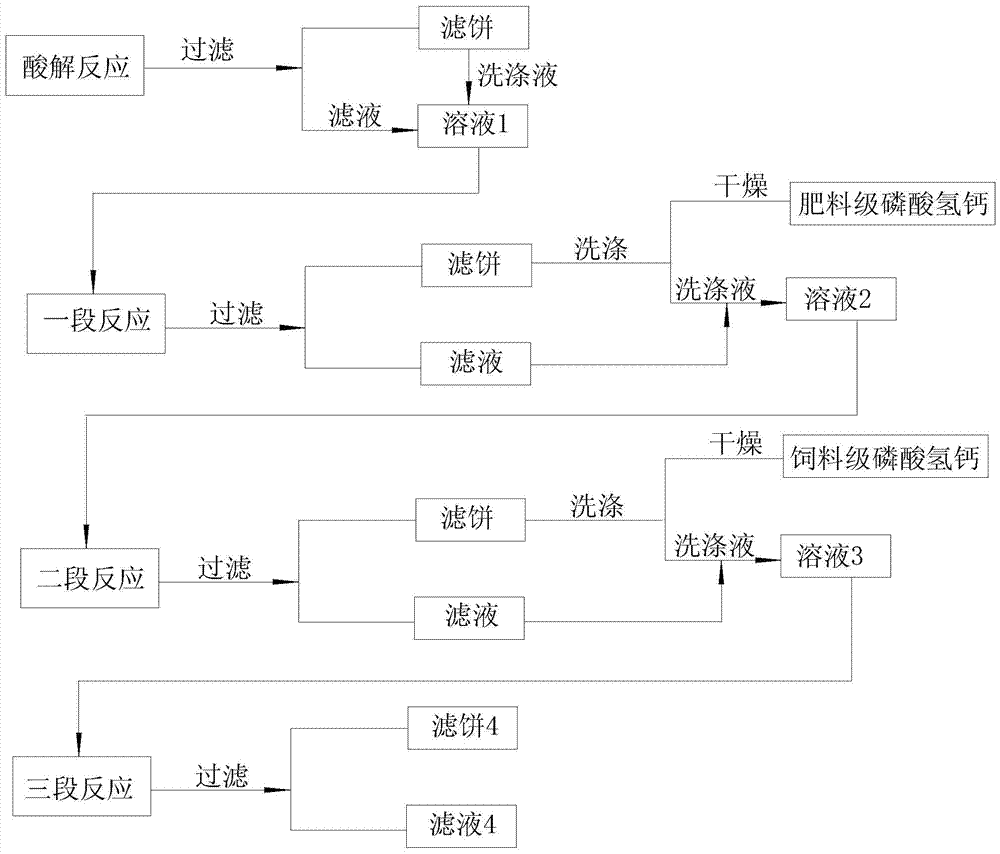

Method used

Image

Examples

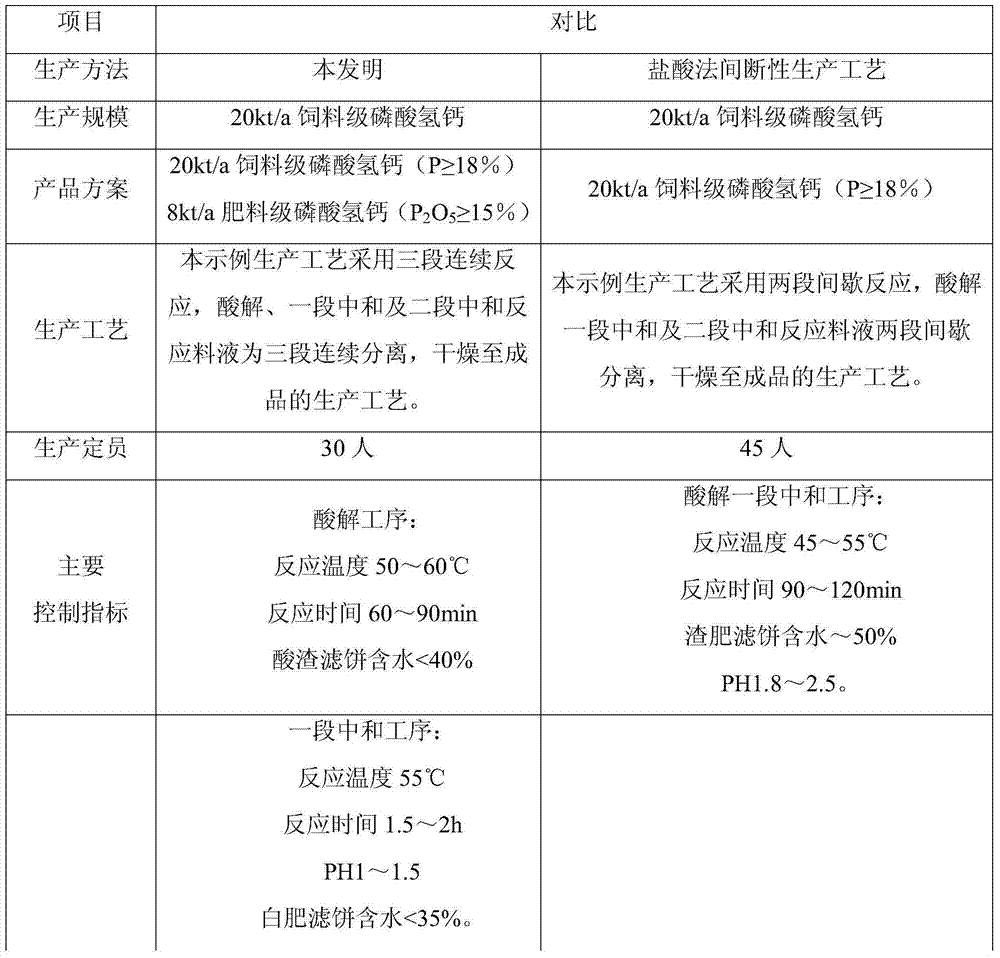

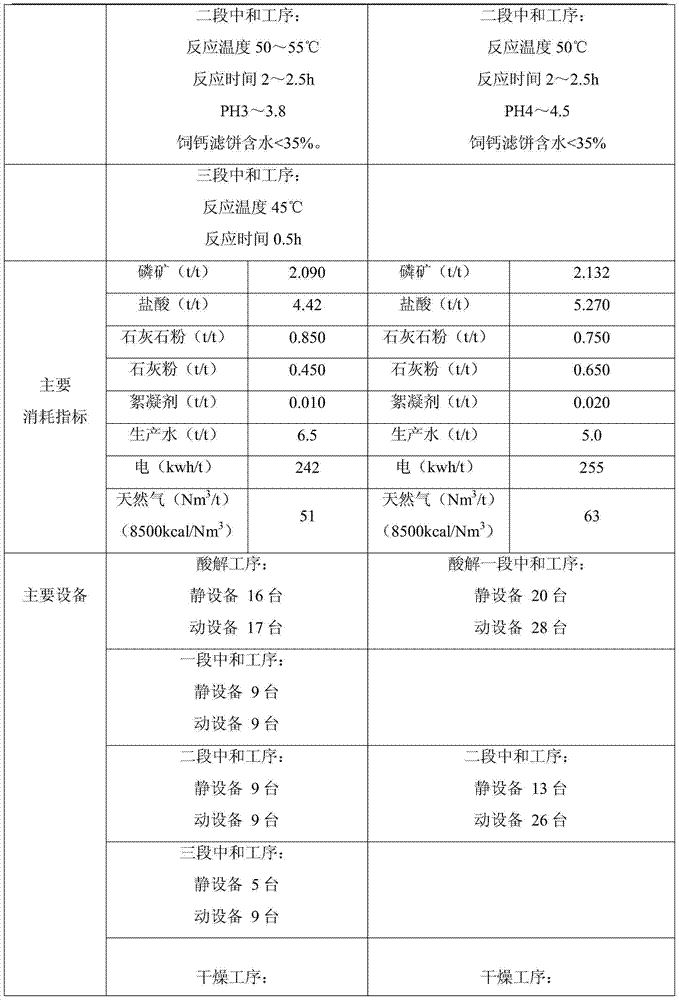

Embodiment 1

[0082] Embodiment 1 adopts the inventive method to continuously produce feed grade calcium hydrogen phosphate

[0083] a. Acid hydrolysis reaction: Mix 13700kg of hydrochloric acid with a concentration of 25wt% and 5850kg of phosphate rock in a continuous and uniform unit time (the phosphate rock is first mixed with water at a weight ratio of 2:1 and ground), and then React at 50°C for 60 minutes, add polyacrylamide (molecular weight > 8,000,000) with a concentration of 3wt‰, filter, wash, and wash at a rate of 1.5m 3 / h, combined filtrate and washings to obtain solution 1;

[0084] b. One-stage neutralization: continuously and uniformly add 650kg calcium carbonate powder (calcium carbonate mixed with water at 3:16 by weight) to solution 1 continuously and uniformly within a unit time, react at 55°C for 1.5h, and the pH of the solution is 1.0, add polyacrylamide (molecular weight >8,000,000) with a concentration of 3wt‰, filter, wash, and wash at a rate of 2m 3 / h, merge fil...

Embodiment 2

[0095] Embodiment 2 adopts the inventive method to continuously produce feed grade calcium hydrogen phosphate

[0096] a. Acid hydrolysis reaction: Mix 12200kg of hydrochloric acid with a concentration of 28wt% and 5850kg of phosphate rock continuously and uniformly within a unit time (the phosphate rock is mixed with water at a weight ratio of 3:2 and ground), and then React at 55°C for 70 minutes, add polyacrylamide (molecular weight > 8,000,000) with a concentration of 4wt‰, filter, wash, and wash at a rate of 2m 3 / h, combined filtrate and washings to obtain solution 1;

[0097] b. One-stage neutralization: Add 700kg of calcium carbonate (prepared by mixing calcium carbonate with water in a weight ratio of 3:17) to solution 1 continuously and evenly per unit time, react at 55°C for 110min, and the pH of the solution is 1.3. Add polyacrylamide (molecular weight greater than >8,000,000) with a concentration of 4wt‰, filter, wash, and wash at a rate of 2.5m 3 / h, merge filt...

Embodiment 3

[0108] Embodiment 3 adopts the inventive method to continuously produce feed grade calcium hydrogen phosphate

[0109] a. Acid hydrolysis reaction: Mix 11,400kg of hydrochloric acid with a concentration of 30wt% and 5,850kg of phosphate rock in a continuous and uniform unit time (the phosphate rock is mixed with water at a weight ratio of 7:3 and ground), and then React at 55°C for 80 minutes, add polyacrylamide (molecular weight greater than >8,000,000) with a concentration of 4wt‰, filter, wash, and wash at a rate of 2m 3 / h, combined filtrate and washings to obtain solution 1;

[0110] b. One-stage neutralization: Add 750kg of calcium carbonate (calcium carbonate is mixed with water in a weight ratio of 1:4) to solution 1 continuously and uniformly within a unit time, react at 55°C for 2 hours, and the pH of the solution is 1.2. Add polyacrylamide (molecular weight greater than >8,000,000) with a concentration of 4wt‰, filter, wash, and wash at a rate of 3m 3 / h, the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com