Method for preparing Fe3O4 nanoparticle/graphene composite material by sol electrostatic self-assembly process and application thereof

A technology of electrostatic self-assembly and nano-particles, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor uniformity of composite materials, poor controllability of composite material components in the chemical preparation process, etc., and achieve assembly The method is simple and feasible, the cost is low, and the effect of the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

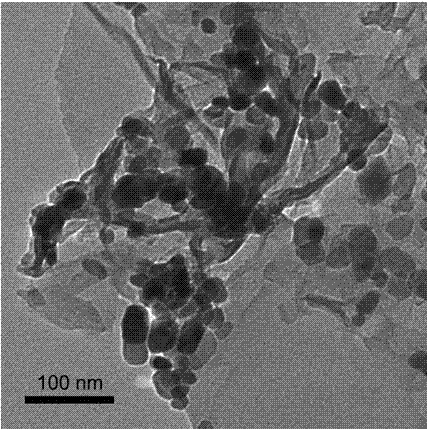

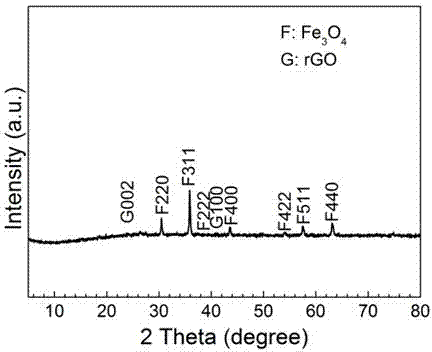

Embodiment 1

[0018] At room temperature, prepare 40 mL of 10% FeCl 3 aqueous solution; take a beaker and fill it with 200mL distilled water, and put the prepared FeCl 3 The aqueous solution is added dropwise into boiling water. After the dropwise addition is completed, boil for 2 minutes. The resulting solution is a brick-red transparent aqueous solution. The solution is in a stable state, which is Fe(OH) 3 hydrosol system. Graphene oxide was prepared by the Hummers method, with a negative charge on the surface; the graphene oxide was ultrasonically dispersed in water so that the concentration of graphene oxide reached 0.1 mg / mL. The positively charged Fe(OH) on the surface 3 Add 10.7mL of the sol to the graphene oxide sol, a brown-black precipitate appears under magnetic stirring, separate, remove the supernatant, and obtain Fe(OH) 3 and graphene oxide composite, the composite was reduced at 500°C under an inert atmosphere to prepare Fe 3 o 4 / graphene composites.

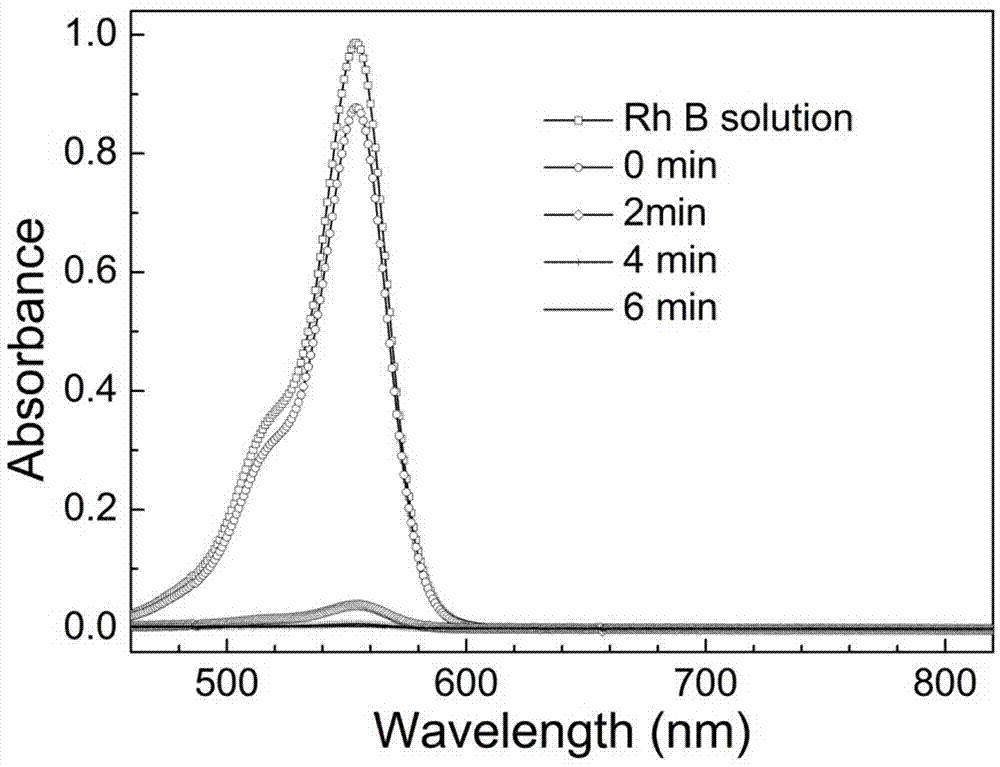

[0019] During t...

Embodiment 2

[0021] At room temperature, prepare 40 mL of 10% FeCl 3 aqueous solution; take a beaker and fill it with 200mL distilled water, and put the prepared FeCl 3 The aqueous solution is added dropwise into boiling water. After the dropwise addition is completed, boil for 2 minutes. The resulting solution is a brick-red transparent aqueous solution, which is in a stable state, which is Fe(OH) 3 hydrosol system. Graphene oxide was prepared by the Hummers method, with a negative charge on the surface; the graphene oxide was ultrasonically dispersed in water so that the concentration of graphene oxide reached 0.1 mg / mL. The positively charged Fe(OH) on the surface 3 Add 5mL of the sol to the graphene sol, a brown-black precipitate appears under magnetic stirring, the upper layer solution is light yellow, separate, remove the upper layer liquid, and obtain Fe(OH) 3 and graphene oxide composite, the composite was reduced at 500°C under an inert atmosphere to prepare Fe 3 o 4 / graphe...

Embodiment 3

[0023] At room temperature, prepare 40 mL of 10% FeCl 3 aqueous solution; take a beaker and fill it with 200mL distilled water, and put the prepared FeCl 3 The aqueous solution is added dropwise into boiling water. After the dropwise addition is completed, boil for 2 minutes. The resulting solution is a brick-red transparent aqueous solution, which is in a stable state, which is Fe(OH) 3 hydrosol system. Adopt Hummers method to prepare graphene oxide (W. S. Hummers and R. E. Offeman, J. Am. Chem. Soc., 1958, 80, 1339.), with a negative charge on the surface; ultrasonically disperse graphene oxide into water so that the concentration of graphene oxide reaches 0.1mg / mL. The positively charged Fe(OH) on the surface 3 Add 20mL of the sol solution into the graphene dispersion, a brown-black precipitate appears under magnetic stirring, and the upper layer solution is light brick red, separate, remove the upper layer liquid, and obtain Fe(OH) 3 and graphene oxide composite, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com