Three-phase biological fluidized bed A/O/O process for treating coking wastewater

A biological fluidized bed, coking wastewater technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the difficult elimination of wastewater oily components and ammonia nitrogen, wastewater treatment technology Outdated, high equipment operating costs and other issues, to achieve the effect of reducing sludge production, saving carbon sources, and reducing alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

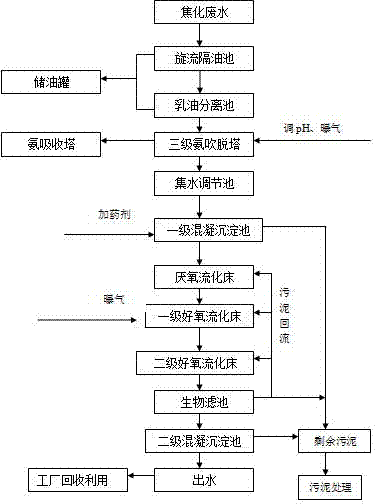

[0016] Such as figure 1 As shown, the present invention provides a three-phase biological fluidized bed A / O / O process for treating coking wastewater, which according to the coking wastewater process includes a degreasing tank, a ammonia removal tower, a catchment regulating tank, and a first-level coagulation sedimentation tank , Anaerobic fluidized bed, primary aerobic three-phase biological fluidized bed, secondary aerobic three-phase biological fluidized bed, biological filter and secondary coagulation sedimentation tank.

[0017] Among them, the coking wastewater passes through the degreasing tank in the first step and is equipped with a rotating degreasing tank, a vertical flow degreasing tank, and an emulsifiable concentrate separation tank. These three facilities use the principles of centrifugal force, gravity and bubble-assisted floatation. Most of the heavy oil and light oil are separated from the oil and sent to the heavy oil and light oil storage tanks by the oil pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com