Preparation method of high-ferrosilicon tailing autoclaved brick

A high-silicon ferrosilicon tailings and high-silicon ferrosilicon technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of large noise and dust pollution, not easy to promote, and large energy consumption. Achieve the effect of reducing dust and noise pollution, reducing grinding process, and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing high-silicon iron tailings autoclaved bricks, comprising the following steps:

[0023] 1. Preparation of high silicon iron tailings powder

[0024] A. Slowly add sulfuric acid with a concentration of 20% to 70% to the untreated iron tailings until the sulfuric acid completely submerges the iron tailings and leave it for 1 to 5 days;

[0025] B. Stir the sample slowly, filter it with a funnel, add water to filter until no sulfuric acid is attached, take it out and dry it to obtain high-silicon iron tailings powder, and the filtrate can be used to prepare ferric sulfate according to the usual method;

[0026] 2. Using the above-mentioned high-silicon iron tailings powder as the main raw material, high-silicon iron tailings pressure-steamed bricks are prepared by steaming

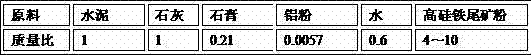

[0027] A. Select raw materials with the following mass ratio

[0028] raw material cement lime plaster Aluminum powder water High silicon iron tailings ...

Embodiment 1

[0037] A method for preparing high-silicon iron tailings autoclaved bricks, comprising the following steps:

[0038] 1. Preparation of high silicon iron tailings powder

[0039] A. Slowly add sulfuric acid with a concentration of 20% to the untreated iron tailings until the sulfuric acid completely submerges the iron tailings and leave it for 1 day;

[0040] The iron tailings are provided by Anshan Iron Mine, and its SiO 2 The mass content is greater than 70%, and its typical chemical composition is shown in the following table:

[0041] Element SiO 2 Al 2 o 3 Fe 2 o 3 FeO CaO MgO K 2 o Na 2 o SO 3 LOI S (%) 76.18 0.61 17.86 2.75 1.16 0.70 0.09 0.10 0.03 0.51 99.3

[0042] B. Stir the sample slowly, filter it with a funnel, add water to filter until no sulfuric acid is attached, take it out and dry it to obtain high-silicon iron tailings powder, and the specific surface area of the powder is measured to be 410m ...

Embodiment 2

[0052] A method for preparing high-silicon iron tailings autoclaved bricks, comprising the following steps:

[0053] 1. Preparation of high silicon iron tailings powder

[0054] A. Slowly add sulfuric acid with a concentration of 20% to the untreated iron tailings until the sulfuric acid completely submerges the iron tailings and leave it for 5 days;

[0055] The iron tailings are provided by Anshan Iron Mine, and its SiO 2 The mass content is greater than 70%, and its typical chemical composition is shown in the following table:

[0056] Element SiO 2 Al 2 o 3 Fe 2 o 3 FeO CaO MgO K 2 o Na 2 o SO 3 LOI S (%) 76.18 0.61 17.86 2.75 1.16 0.70 0.09 0.10 0.03 0.51 99.3

[0057]B. Stir the sample slowly, filter it with a funnel, add water to filter until no sulfuric acid is attached, take it out and dry it to obtain high-silicon iron tailings powder, and the specific surface area of the powder is measured to be 605m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com