Preparation process for waxy wheat Daqu and application of waxy wheat

A preparation process, waxy wheat technology, which is applied in the field of wine making, can solve the problems of undiscovered natural waxy wheat, etc., and achieve the effects of improving acid protease activity, good application prospects, and promoting growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation process of the waxy wheat Daqu of the present invention includes the steps of moistening, crushing, mixing, pressing to make koji, cultivating bacteria in a koji room, turning the koji, and storing it in a warehouse to prepare the finished Daqu. The raw materials for preparing the Daqu include waxy wheat.

[0019] Preferably, in the above process, the raw materials for preparing Daqu are calculated by weight percentage: 25-100% of waxy wheat and 0-75% of durum wheat.

[0020] Preferably, in order to improve the quality of Daqu, in the above process, the particle size of raw materials for preparing Daqu is 45-65% of the amount passed through a 20-mesh sieve.

[0021] Preferably, in order to improve the quality of Daqu, the temperature of the water during the moistening is 80-87° C., the time for moistening is 4-24 hours, and the moisture content of the material after moistening reaches 12-14%.

[0022] Preferably, in order to improve the quality of Daqu, ...

Embodiment 1

[0032] Embodiment 1 adopts the preparation process of the present invention to prepare medium-high temperature Daqu

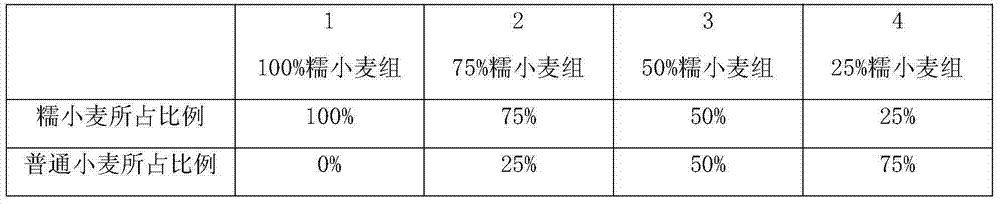

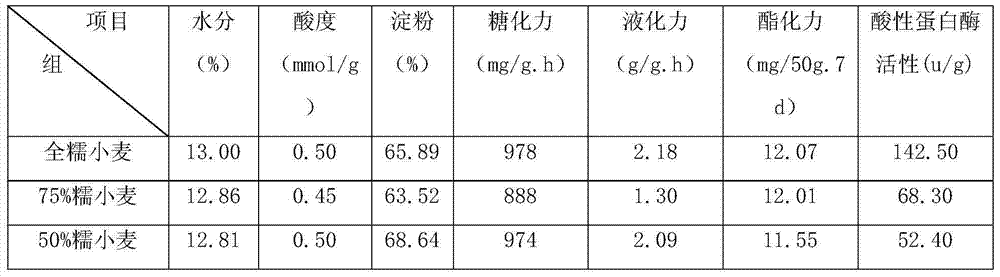

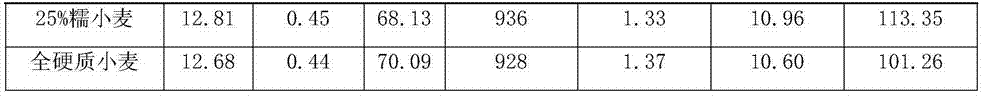

[0033] In this example, waxy wheat and durum wheat were evenly mixed according to different proportions (see Table 1), and the particle size of the raw materials was 45-65% of the amount passed through a 20-mesh sieve.

[0034] The composition of each group of Daqu raw materials in table 1

[0035]

[0036] (1) Moisten, pulverize and mix the uniformly mixed wheat of each group respectively. When moistening the material, the temperature of the water is 80-87°C, the time for moistening the material is 4-24 hours, and the moisture content of the material after moistening reaches 12-14%. Requirements for mixing materials: moderate flow of wheat flour and water, and even mixing. Sensory quality after mixing: uniform draft, no ash or bumps, no sticky hands when kneaded into balls; the temperature of water used for mixing is 30°C, and the water content of raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com