Environment-friendly anodic oxidation pretreatment process

A technology of anodizing and process method, applied in the direction of electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of damage to the surface of parts, high alkali concentration, poor treatment effect of particle-reinforced aluminum matrix composite materials, etc. Achieve the effect of avoiding over-corrosion and low corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A kind of environment-friendly anodic oxidation pretreatment process method provided by the present invention is introduced below in conjunction with embodiment:

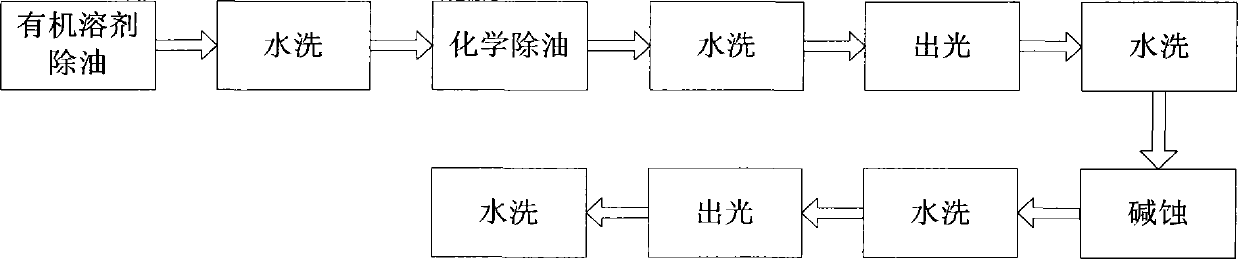

[0025] like figure 1 Shown, a kind of environment-friendly anodic oxidation pretreatment process method, comprises the following steps successively:

[0026] Step 1: Organic solvent degreasing.

[0027] Step 2: Chemical degreasing.

[0028] Step 3: light emitting; the formula of light emitting solution is sulfuric acid 230-270g / L, potassium permanganate is 0.8-1.2g / L;

[0029] Step 4: Alkali etching; the formula of alkaline etching solution is 50-60g / L of sodium hydroxide, 0.1g / L-0.5g / L of any one of sodium citrate, sodium tartrate and sodium gluconate;

[0030] Step 5: light emitting; the formula of light emitting solution is 230-270 g / L of sulfuric acid and 0.8-1.2 g / L of potassium permanganate.

[0031] In order to achieve better results, each step can be optimized as follows:

[0032] Step 1: Organic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com