Dimming window with liquid crystal dimming strips arrayed in grid shape

A liquid crystal dimming and grid-shaped technology, applied in the field of dimming windows, can solve the problems of obvious seams, strengthening the strength of liquid crystal dimming films, affecting the appearance of dimming windows, etc., to improve the overall strength, improve yield, and easily culling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

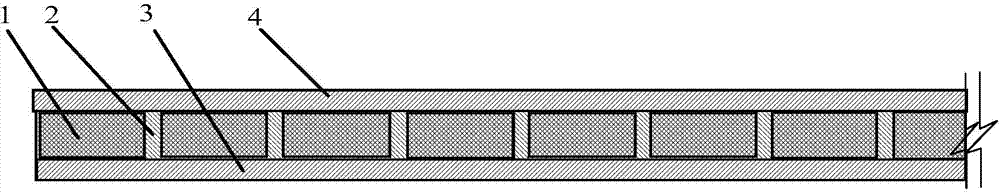

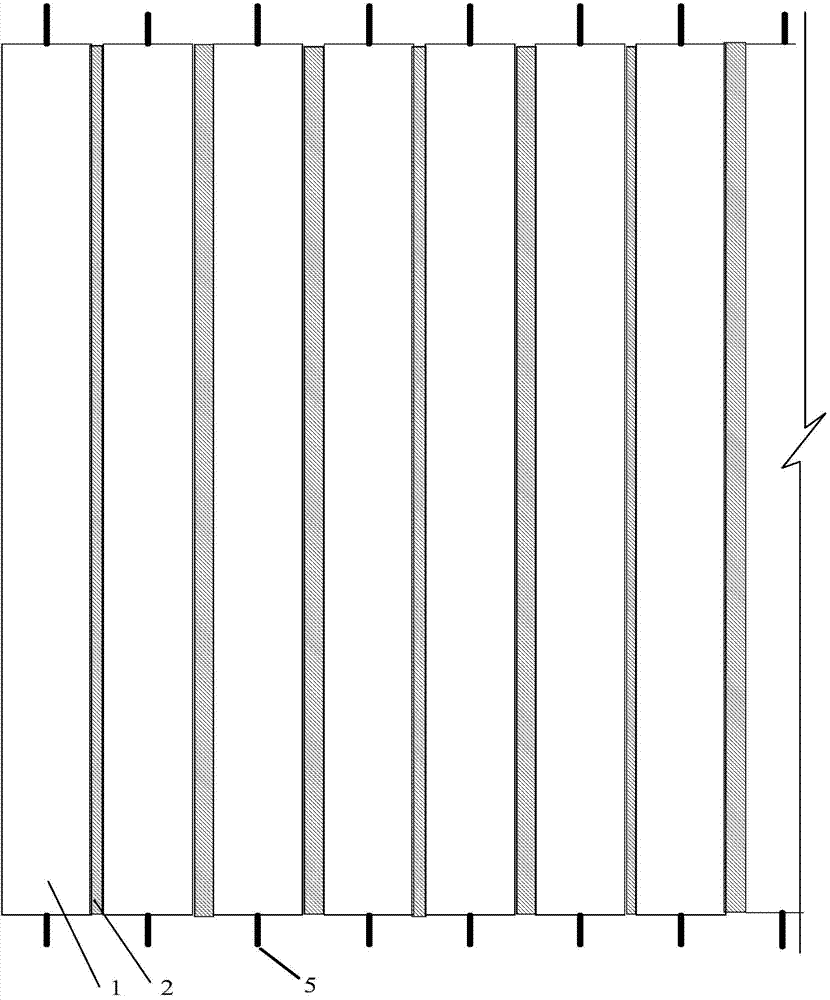

[0051] Such as figure 1 , 2 As shown, the dimming window in which the liquid crystal dimming strips are arranged in a grid shape includes a liquid crystal dimming strip 1 , an adhesive strip 2 and two upper and lower transparent substrates 3 and 4 . The upper and lower transparent substrates 3 and 4 are plexiglass plates, and polycarbonate plates and glass plates can also be used; the adhesive strip 2 is an acrylic monomer or prepolymer injected into the adjacent liquid crystal dimming strip 1 After the gap between them is formed by polymerization and curing under ultraviolet light; the lead-out electrodes of the liquid crystal dimming strip 1 are drawn out in any known manner.

[0052] The above structure can be realized by the following steps:

[0053] Step 1): Use laser cutting or mechanical cutting to cut the commercial liquid crystal dimming film into strips along the length direction, and leave the positions of electrodes on the short sides of the two ends respectively...

Embodiment 2

[0060] Such as figure 1 , 2 As shown, the dimming window in which the liquid crystal dimming strips are arranged in a grid shape includes a liquid crystal dimming strip 1 , an adhesive strip 2 and two upper and lower transparent substrates 3 and 4 . The upper and lower transparent substrates 3 and 4 are both plexiglass plates, polycarbonate plates, or glass plates; the adhesive strip 2 is a hot-melt film material that flows to the liquid crystal dimming strip 1 after heating and melting The gap between the positions is formed after cooling.

[0061] The specific manufacturing steps are given below:

[0062] Step i): Use laser cutting or mechanical cutting to cut the commercial liquid crystal dimming film into strips along the length direction, leave the positions of electrodes on the short sides of both ends, and lead out the metal wires with the existing technology, according to In the existing known technology, the electrodes are respectively bonded and fixed with conduct...

Embodiment 3

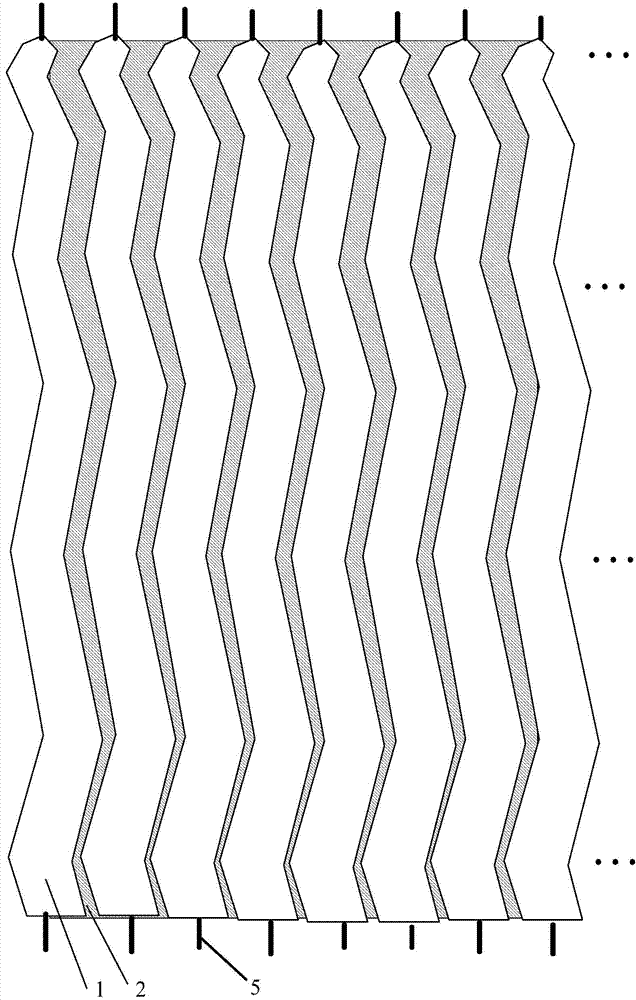

[0069] Such as image 3 shown with the removed figure 1 The top view of the structure after the upper and lower transparent substrates 3 and 4 in . The strip-shaped liquid crystal dimming strips 1 surrounded by polygons and arcs are arranged in a grid structure; each liquid crystal dimming strip 1 satisfies the condition that the ratio of its length to the average width is greater than 10:1; the adhesive strip The average width of 2 is between 0.2mm and 5mm. The structure of the dimming window in which the liquid crystal dimming bars are arranged in a grid shape can be realized by the same method as in the first or second embodiment, so the description will not be repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com