Software control method for I-bar welding robot

A welding robot and software-controlled technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of inconvenient operation, low work efficiency, and low degree of automation in coating welding, so as to improve welding efficiency and reduce labor. Strength, health damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

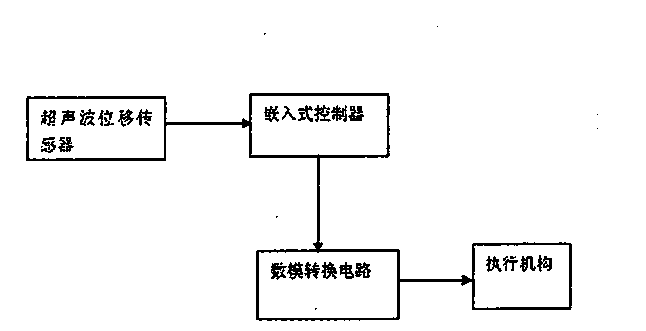

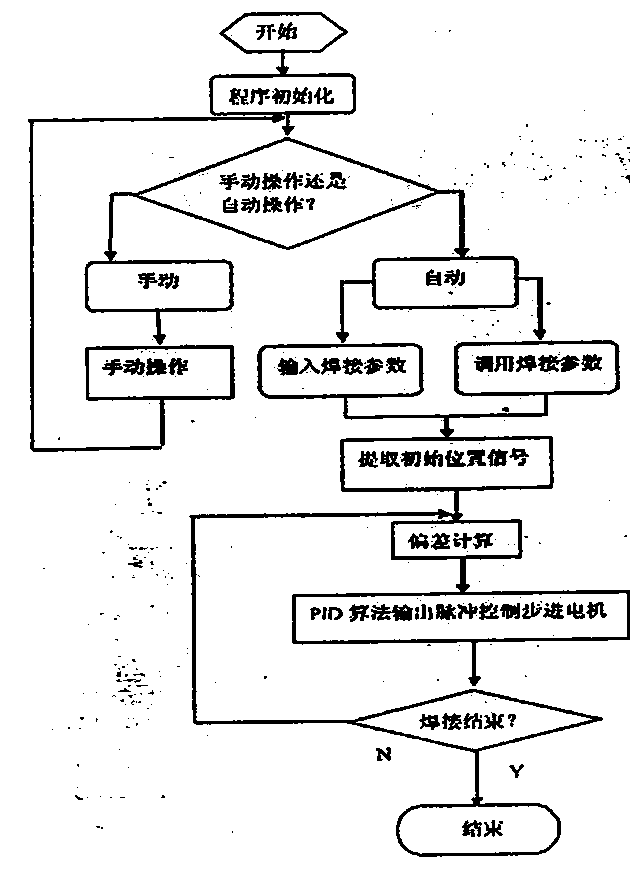

[0007] 1. The principle of the I-beam welding robot control system: The structure of the I-beam is regular, but the welding seam cannot be guaranteed to be a horizontal straight line when the workpiece is placed in the ship shape. In order to ensure the uniformity and flatness of the welding, it is necessary to automatically adjust the welding torch and welding The relative position of the seam, but the use of the coating will cover the weld seam during welding, and ordinary sensors cannot directly track the weld seam.

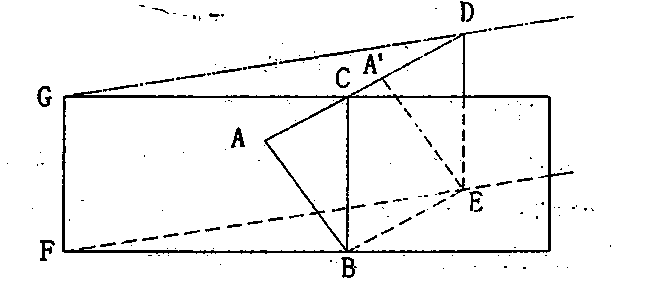

[0008] As shown in the weld seam offset diagram in Figure 1, GFBC is a longer "V" surface when the I-beam is placed in the ship shape, AB is the welding torch, and AC is the horizontal displacement of the ultrasonic displacement sensor to the surface GFBC , if the I-beam is not placed horizontally and is offset to the surface GFED, at this time the welding torch needs to track the welding seam point A to move to point A', and point B to move to point E. Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com