Optical Fiber Bragg Grating Sensing System and Operation Method Based on Narrowband Scanning Light Source

A fiber grating and sensing system technology, applied in the direction of using optical devices, thermometers with physical/chemical changes, measuring devices, etc., can solve the problems of poor signal-to-noise ratio of sensing signals, low utilization of light sources, and problems that can be demodulated Problems such as the number of sensors and demodulation accuracy, to achieve high signal-to-noise ratio, improve demodulation speed, and improve scanning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

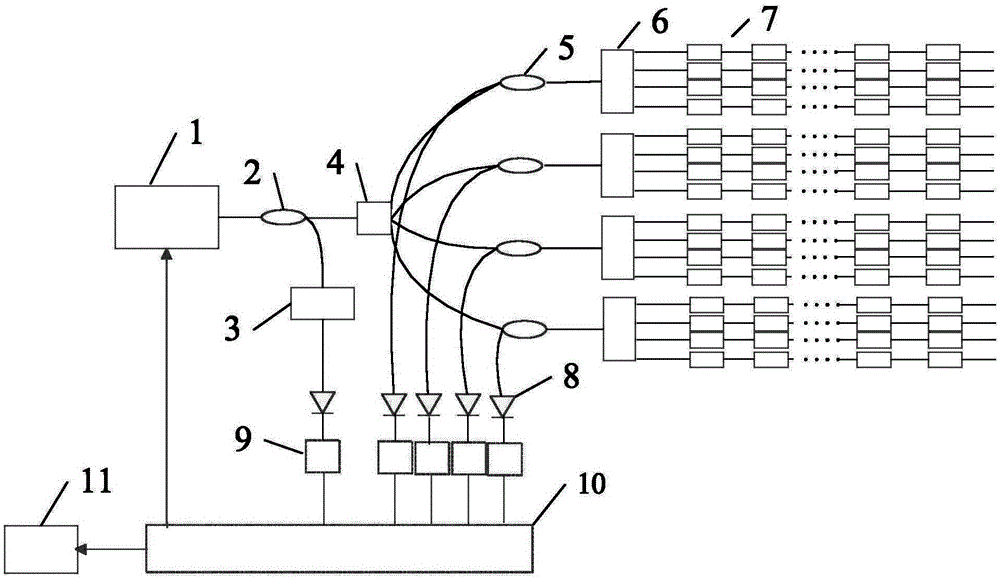

[0028] Embodiment 1 of the fiber grating sensing system based on narrowband scanning light source figure 1As shown, it includes tunable laser 1, 1X2 coupler 2, 1×4 coupler 4, circulator 5, photodetector 8 and 16 sensor channels 7. The tunable laser 1 in this example is a tunable fiber grating-based For the laser, the volume grating-based tunable laser is the same as in this case. The wavelength variation range of the narrow-band light wave whose wavelength is periodically changed by the tunable laser 1 covers the wavelength variation range of each fiber grating sensor in the system. The 1×2 coupler 2 splitting ratio of the example is 90 / 10, 90% of the laser beam is connected to the 1×4 coupler 4, and 10% of the laser beam is connected to the etalon 3. The 2 split from the 1×2 coupler 2 One of the laser channels is connected to a 1×4 coupler 4 to be divided into four sensor channels 7, and the other channel is connected to an etalon 3 as a calibration channel, and the etalon 3...

Embodiment 2

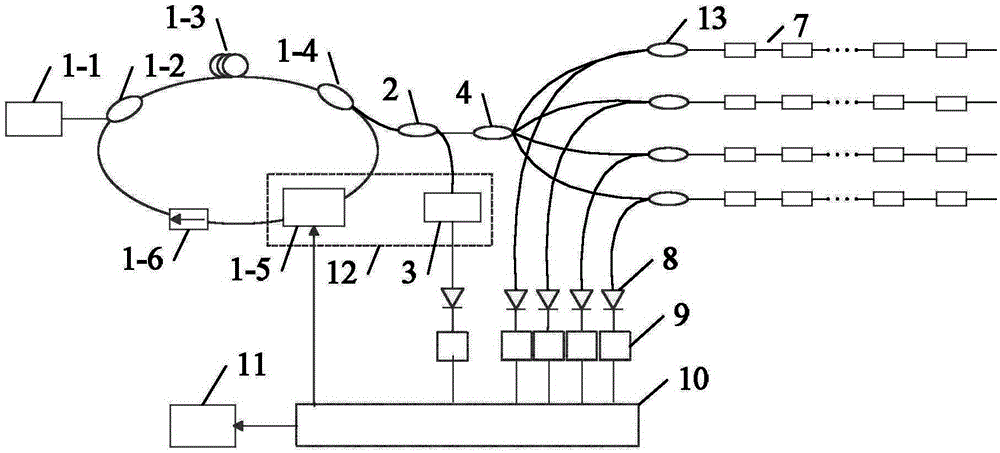

[0032] Embodiment 2 of the fiber grating sensing system based on narrowband scanning light source figure 2 As shown, its basic structure is similar to that of Embodiment 1, and its 4 circulators are replaced by 4 identical 2×1 couplers 13, and the etalon 3 of this example is F-P (Fabry-Perot Fabry-Perot) standard Tool.

[0033] The tunable laser 1 is a ring cavity tunable laser based on an F-P filter, including a pump laser 1-1, a wavelength division multiplexer 1-2, an erbium-doped fiber 1-3, and a laser 1×2 coupler 1- 4. Tunable F-P filter 1-5 and fiber isolator 1-6; the laser output from the pump laser 1-1 is connected to the wavelength division multiplexer 1-2, and the output of the wavelength division multiplexer 1-2 is sequentially connected to the doped Erbium fiber 1-3, laser 1×2 coupler 1-4, tunable F-P filter 1-5 and fiber isolator 1-6, the output end of fiber isolator 1-6 is also connected to wavelength division multiplexer 1 The input end of -2 constitutes the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com