Semiconductor device production method and semiconductor device

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of increased reverse leakage, increased reverse leakage, and inability to add, etc. Excellent insulation, low reverse leakage current, and improved insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

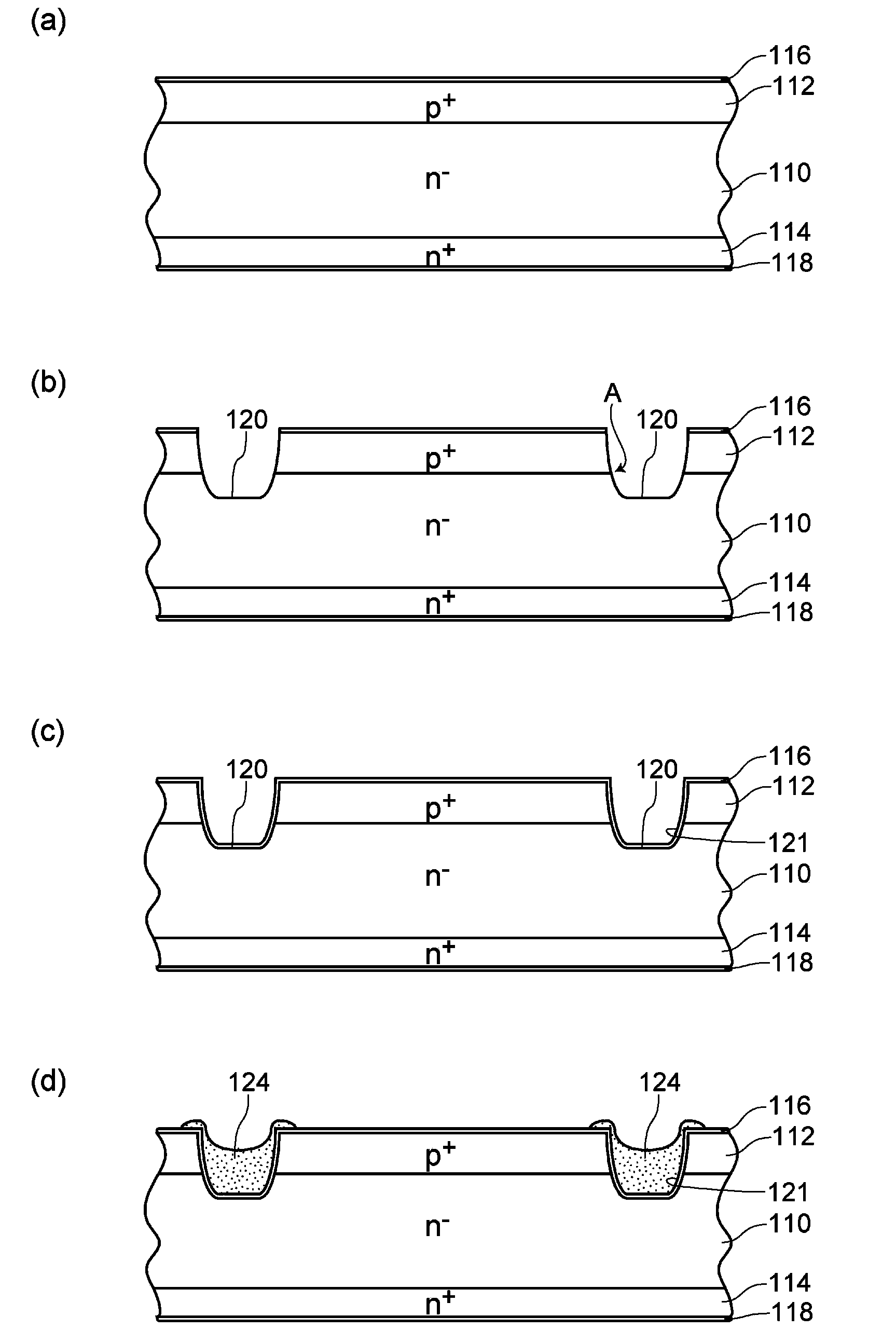

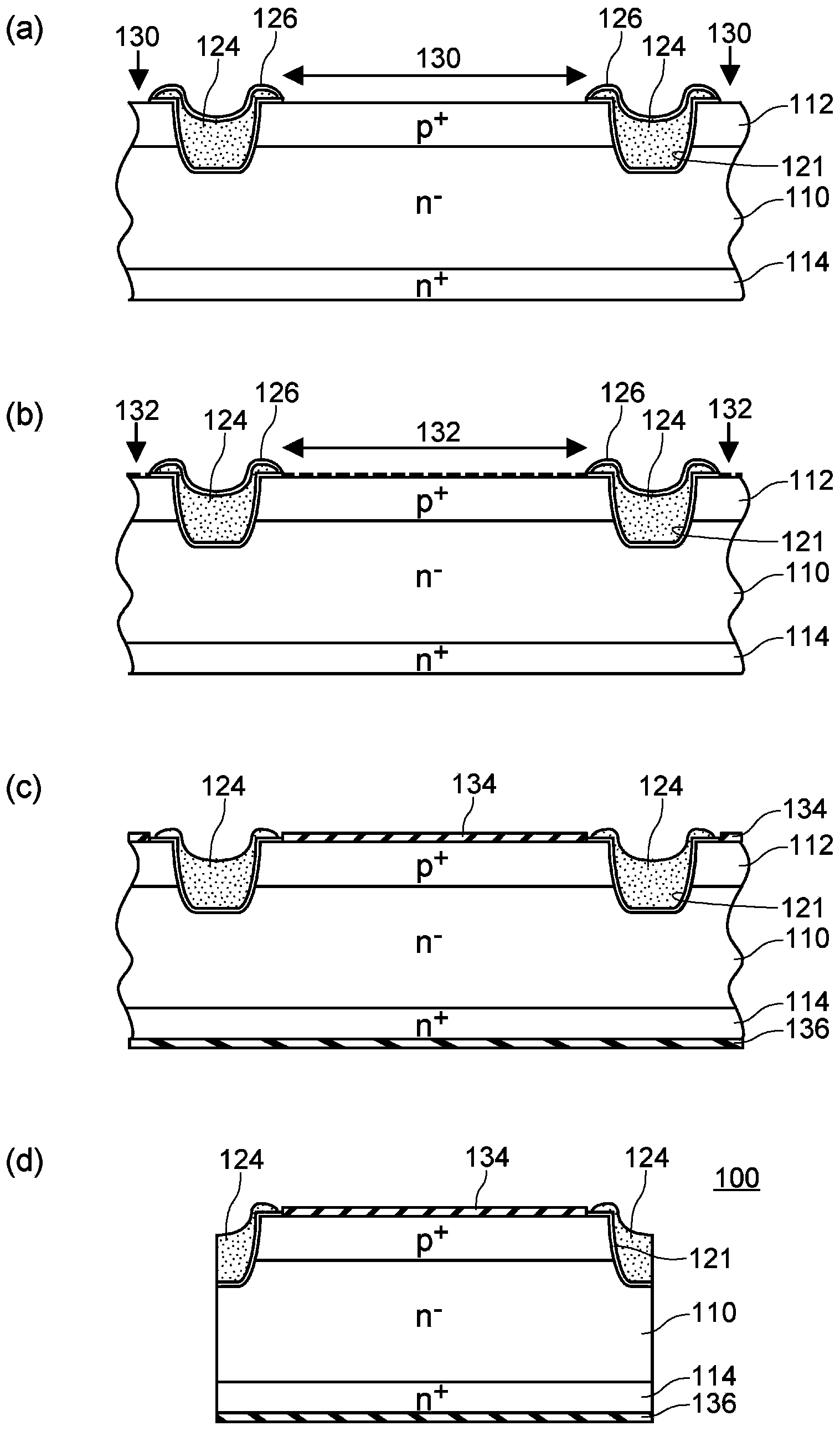

[0081] The method for manufacturing a semiconductor device according to Embodiment 1 includes in order: a first step of preparing a semiconductor element having a pn junction exposed portion; a second step of forming an insulating layer covering the pn junction exposed portion; and a third step of After forming a layer made of a glass compound for protecting a semiconductor junction on the insulating layer, the layer made of the glass compound for protecting a semiconductor junction is fired to form a glass layer on the insulating layer. In the method of manufacturing a semiconductor device according to Embodiment 1, a mesa-type pn diode is manufactured as a semiconductor device.

[0082] figure 1 and figure 2 It is a figure for demonstrating the manufacturing method of the semiconductor device of Embodiment 1. figure 1 (a) ~ figure 1 (d) and figure 2 (a) ~ figure 2 (d) is a diagram of each process.

[0083] like figure 1 and figure 2 As shown, the manufacturin...

Embodiment approach 2

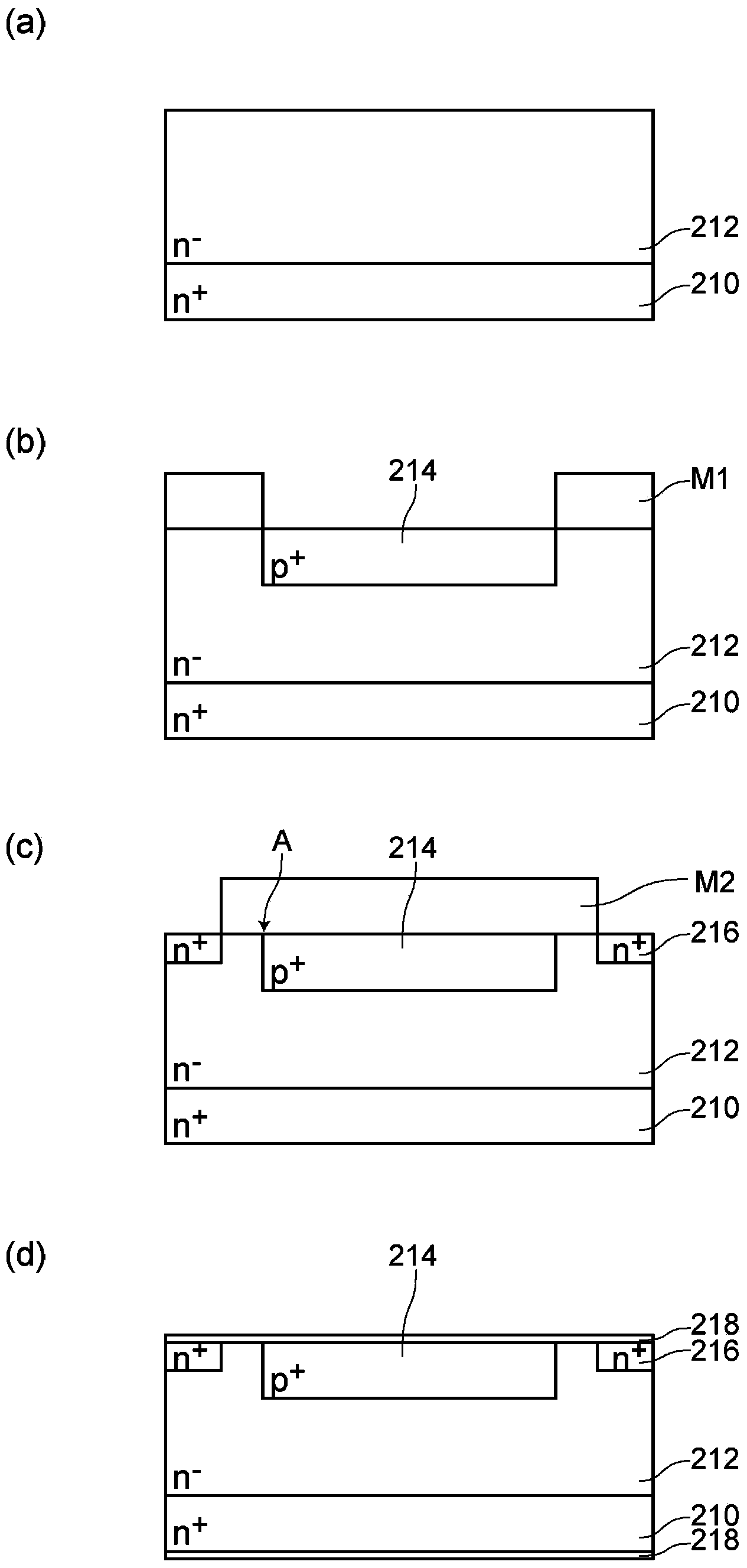

[0125] The method of manufacturing a semiconductor device according to Embodiment 2, like the method of manufacturing a semiconductor device according to Embodiment 1, sequentially includes the first step of preparing a silicon semiconductor element having a pn junction exposed portion; the second step, forming an insulating layer covering the exposed portion of the pn junction; and a third step of forming a layer made of a glass compound for protecting a semiconductor junction on the insulating layer, and then firing the layer made of a glass compound for protecting a semiconductor junction. A method of manufacturing a semiconductor device in which a glass layer is formed on an insulating layer. However, in the method of manufacturing a semiconductor device according to Embodiment 2, a difference from the method of manufacturing a semiconductor device according to Embodiment 1 is that a planar type pn diode is manufactured as a semiconductor device.

[0126] image 3 with ...

Embodiment approach 3

[0154] The manufacturing method of the semiconductor device related to the third embodiment, like the manufacturing method of the semiconductor device related to the first embodiment, includes the first step in sequence, preparing a semiconductor element having a pn junction exposed portion where the pn junction is exposed; the second step, forming a covering The insulating layer of the exposed part of the pn junction; and the third step, after forming a layer made of the glass compound for semiconductor junction protection on the insulating layer, by firing the layer made of the glass compound for semiconductor junction protection, on the insulating layer A method of manufacturing a semiconductor device on which a glass layer is formed. In addition, as the glass compound for protecting a semiconductor joint, a glass compound for protecting a semiconductor joint is used, which is composed of glass fine particles obtained from a melt obtained by melting a raw material containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com