A kind of adsorbent for treating acrylonitrile wastewater and its preparation method and application

A technology of acrylonitrile waste water and adsorbent, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve secondary pollution and other problems, and is beneficial to the load and the environment Protective, widely distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

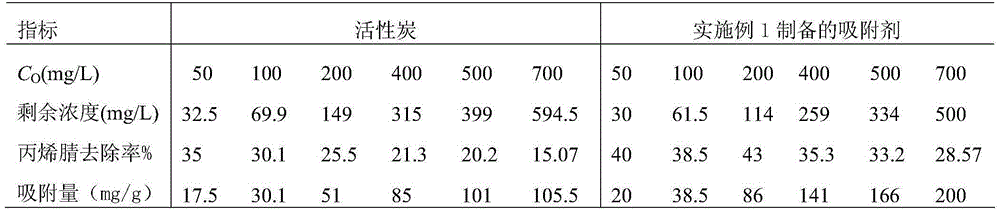

Examples

Embodiment 1

[0033] A preparation method of an adsorbent for treating acrylonitrile waste water, the steps are as follows:

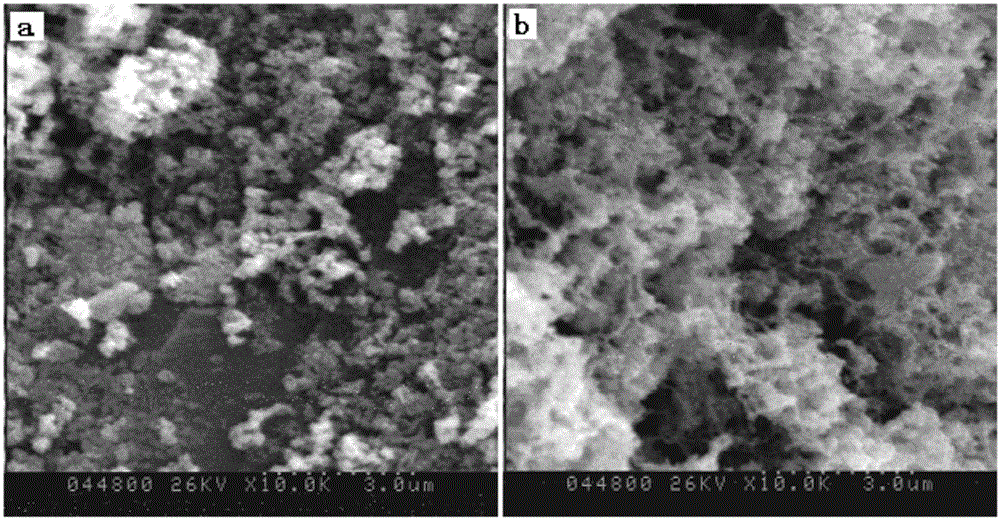

[0034] (1) Wash and remove impurities from the root of Arundis reed, cut it into sections, and dry it in an oven at 105°C for 12 hours. The dried Arundis root is pulverized in a pulverizer and passed through a 80-mesh sieve to obtain Arundis root powder; Immerse the root powder of reed bamboo in 45% pyrophosphoric acid aqueous solution for 10 hours, the mass ratio of the root powder of reed bamboo to the solution of pyrophosphoric acid is 1:1, take out the root powder of reed bamboo soaked above and place In a muffle furnace, carbonize and activate at 500°C for 1 hour, stop heating, cool, wash with deionized water at 100°C until the pH of the washing solution remains unchanged, and dry to obtain activated carbon particles;

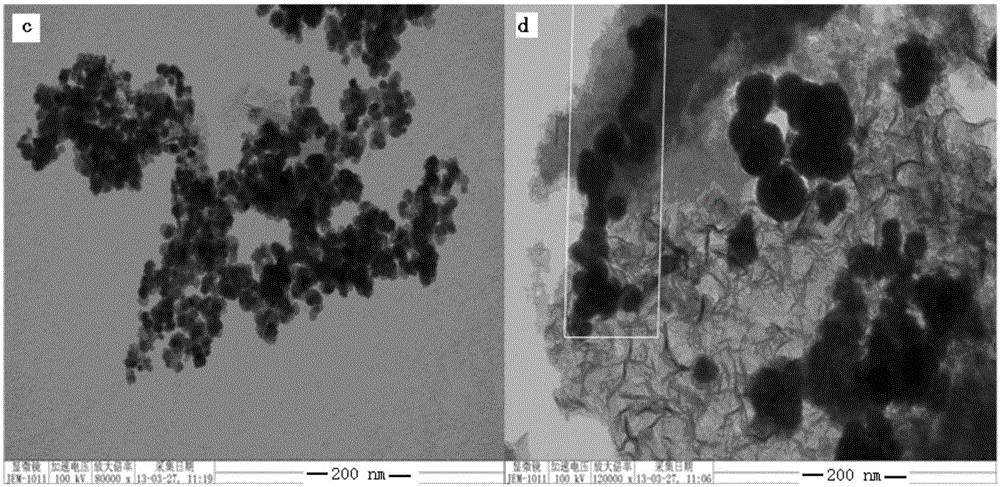

[0035] (2) Add 2 g of the activated carbon particles obtained in step (2) to 100 ml of 0.07 mol / L ferrous sulfate solution, stir and soak for 4 ...

Embodiment 2

[0039] A kind of preparation method of the adsorbent of processing acrylonitrile waste water, step is the same as embodiment 1, difference is:

[0040]The dried reed bamboo root in the step (1) is pulverized in a pulverizer and passed through a 200-mesh sieve to obtain a reed bamboo root powder; the mass concentration of the pyrophosphoric acid solution is 40%; the carbonization activation temperature in the muffle furnace is 600°C ; The molar concentration of the ferrous sulfate solution in step (2) is 0.1mol / L.

[0041] The adsorbent for the treatment of acrylonitrile wastewater prepared in this example is measured by the specific surface area analyzer as having a specific surface area of 422.25m 2 / g, the average pore size is 4.37nm, the average particle size is 150.26μm, and the iron loading is 10.5%.

Embodiment 3

[0043] A preparation method of an adsorbent for treating acrylonitrile waste water, the steps are as follows:

[0044] (1) Wash and remove impurities from the root of Reed Bamboo, cut it into sections, and dry it in an oven at 105°C for 12 hours. After the dried root of Reed Bamboo is crushed in a pulverizer, it passes through a 200-mesh sieve to obtain root powder of Reed Bamboo;

[0045] Soak the root powder of reed bamboo in 45% pyrophosphoric acid aqueous solution for 10 hours, the mass ratio of the root powder of reed bamboo to the solution of pyrophosphoric acid is 1:2, take out the root powder of reed bamboo soaked above and place In a muffle furnace, carbonize and activate at 500°C for 1 hour, stop heating, cool, wash with deionized water at 90°C until the pH of the washing liquid remains unchanged, and dry naturally to obtain activated carbon particles;

[0046] (2) Add 2 g of activated carbon particles obtained in step (2) to 100 ml of 0.07 mol / L ferrous sulfate solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com