Preparation method of monolayer SiO2 antireflection film

An anti-reflection film, single-layer technology, applied in the field of preparation of single-layer SiO2 anti-reflection film, to achieve excellent chemical stability, overall appearance, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

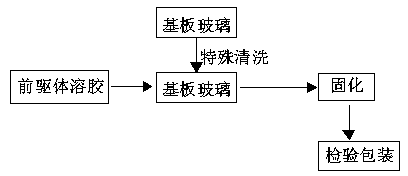

Method used

Image

Examples

Embodiment 1

[0030] (1) Substrate glass pretreatment: Ultrasonic the substrate glass in acetone solution and ethanol solution for 30 minutes respectively;

[0031] (2) SiO 2 Preparation of sol: The sol was synthesized in two steps:

[0032] A) Preparation of acidic dilute SiO by traditional sol-gel method 2 The sol is used as the matrix solution, and the preparation method is as follows: TEOS, ethanol and water are used as precursors, mixed according to the molar ratio of 1:30:4, added hydrochloric acid to adjust the pH to 2, stirred evenly, and aged at room temperature for 1 to 10 days. ;

[0033] B) Disperse the nano-silica powder in the ethanol solution, then add the B solution into the A solution according to the weight ratio of the B solution to the A solution of 1:2, and stir it evenly to become a subsequent coating sol;

[0034] (3) Coating film by sol: use dipping and pulling method to coat the surface of the glass substrate to form a film with a thickness of 120-130nm;

[0035...

Embodiment 2

[0038] (1) Substrate glass pretreatment: Ultrasonic the substrate glass in acetone solution and ethanol solution for 30 minutes respectively;

[0039] (2) SiO 2 Preparation of sol: The sol was synthesized in two steps:

[0040] A) Preparation of acidic dilute SiO by traditional sol-gel method 2 The sol is used as the matrix solution, and the preparation method is as follows: TMOS, methanol and water are used as precursors, mixed according to the molar ratio of 1:30:4, added hydrochloric acid to adjust the pH to 5, stirred evenly, and aged at room temperature for 10 days;

[0041] B) Disperse the nano-silica powder in the ethanol solution; then add the B solution into the A solution according to the weight ratio of the B solution to the A solution of 1:10, and stir it evenly to become a subsequent coating sol;

[0042] (3) Sol-coating mold making: Spin coating is used to coat the surface of the glass substrate to form a 130nm-thick film;

[0043] (4) Film curing: The film i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com