Preparation method of 1,4-cyclohexanedimethanol

A technology of cyclohexane dimethanol and dimethyl toluate, which is applied in the field of preparation of chemical intermediates, can solve the problems of high hydrogenation pressure, achieve the effects of increasing yield, realizing catalytic hydrogenation reaction, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

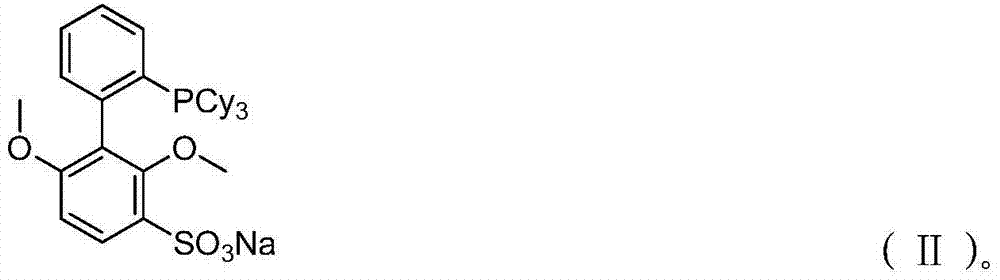

Embodiment 1

[0026] In a 500mL autoclave, add 200g of water as a solvent, dimethyl terephthalate (19g, 0.1mol), RhCl 3 .3H 2 O (0.13g, 0.5mmol), the phosphine ligand represented by formula (II) (0.59g, 1mmol). After sealing the autoclave, extract the air in the autoclave, and replace it with nitrogen and hydrogen in sequence. Under the hydrogen pressure of 1.0MPa, stir and heat to 80°C to start the reaction. Keep the required hydrogen pressure until the reaction is completed. After six hours, cool and filter. The reaction solution was analyzed by gas chromatography, and the internal standard method was used to calculate the concentration of the reactant, the concentration of the intermediate product and the concentration of the product 1,4-cyclohexanedimethanol, and the reaction conversion rate was 93.5%, and the 1,4-cyclohexane The selectivity of dimethanol is 98.3%; among them, the mass ratio of trans 1,4-cyclohexanedimethanol to cis 1,4-cyclohexanedimethanol is 6.5:1, trans 1,4-cyclohe...

Embodiment 2

[0029] In a 500mL autoclave, sequentially add 200g of water as a solvent, dimethyl terephthalate (19g, 0.1mol), rhodium (II) acetate dimer (CAS: 15956-28-2, 0.22g, 0.5mmol ), the phosphine ligand represented by formula (II) (0.59 g, 1 mmol). After sealing the autoclave, extract the air in the autoclave, and replace it with nitrogen and hydrogen in sequence. Under the hydrogen pressure of 1.0MPa, stir and heat to 80°C to start the reaction. Keep the required hydrogen pressure until the reaction is completed. After six hours, cool and filter. The reaction solution was analyzed by gas chromatography, and the internal standard method was used to calculate the concentration of the reactant, the concentration of the intermediate product and the concentration of the product 1,4-cyclohexanedimethanol, and the reaction conversion rate was 90.1%, and the 1,4-cyclohexane The selectivity of dimethanol is 94.5%; among them, the mass ratio of trans 1,4-cyclohexanedimethanol to cis 1,4-cyclo...

Embodiment 3

[0031] In a 500mL autoclave, sequentially add 200g of n-butanol as solvent, dimethyl terephthalate (19g, 0.1mol), RhCl 3 .3H 2 O (0.13g, 0.5mmol), the phosphine ligand represented by formula (II) (0.59g, 1mmol). After sealing the autoclave, extract the air in the autoclave, and replace it with nitrogen and hydrogen in sequence. Under the hydrogen pressure of 1.0MPa, stir and heat to 80°C to start the reaction. Keep the required hydrogen pressure until the reaction is completed. After six hours, cool and filter. The reaction solution was analyzed by gas chromatography, and the internal standard method was used to calculate the concentration of the reactant, the concentration of the intermediate product and the concentration of the product 1,4-cyclohexanedimethanol, and the reaction conversion rate was 91.2%. 1,4-cyclohexane The selectivity of dimethanol is 93.8%, among which, the mass ratio of trans 1,4-cyclohexanedimethanol to cis 1,4-cyclohexanedimethanol is 6:1, trans 1,4-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com