Method for preparing 7-chloroquinaldine by use of phase-transfer catalytic reaction

A phase transfer catalysis and reaction technology, applied in the direction of organic chemistry, etc., can solve the problems of harsh process conditions, product loss, high price of tetrachloro-p-benzoquinone, and achieve the effects of improving reaction efficiency, increasing emulsification, and simple post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

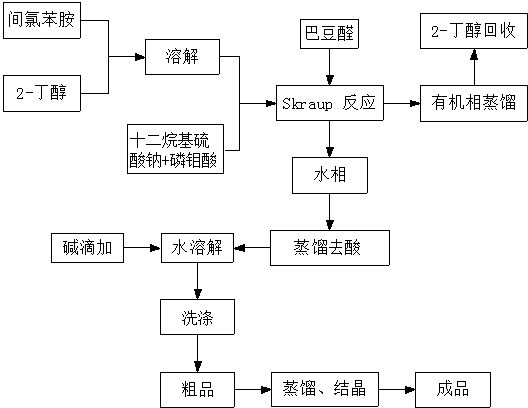

Method used

Image

Examples

Embodiment 1

[0024] First dissolve 12.7g m-chloroaniline in 50mL of organic solvent 2-butanol, add it to a three-necked flask and stir, add 14.4g of surfactant sodium lauryl sulfate and 18.25g of oxidant phosphomolybdic acid, add 100mL of aqueous solution and The mixed solvent of 2-butanol was stirred at 80 °C for 1 h; then 7 g of crotonaldehyde was added dropwise to the mixture, and the reaction was continued at 80 °C for 4 h; after the reaction, the mixture was layered, and 2-butanol was recovered from the organic phase , the aqueous phase was distilled under reduced pressure to remove acid, and the 3 The solution was washed and recrystallized from ethanol to obtain high-purity 7-chloroquinaldine with a yield of 85%.

Embodiment 2

[0026] First dissolve 12.7g m-chloroaniline in 50mL of organic solvent 2-butanol, add it to a three-necked flask and stir, add 28.8g of surfactant sodium lauryl sulfate and 36.5g of oxidant phosphomolybdic acid, add 100mL of aqueous solution and The mixed solvent of 2-butanol was stirred at 85°C for 2h; then 7g of crotonaldehyde was added dropwise to the mixture, and the reaction was continued at 85°C for 3h; after the reaction, the mixture was layered, and 2-butanol was recovered from the organic phase , the aqueous phase was distilled under reduced pressure to remove the acid, and the aqueous phase was distilled off with 8wt% 100mL NaHCO 3 The solution was washed and recrystallized with ethanol to obtain high-purity 7-chloroquinaldine with a yield of 83%.

Embodiment 3

[0028] First dissolve 12.7g m-chloroaniline in 50mL of organic solvent 2-butanol, add it to a three-necked flask and stir, add 20.4g of surfactant sodium lauryl sulfate and 30.5g of oxidant phosphomolybdic acid, add 100mL of aqueous solution and The mixed solvent of 2-butanol was stirred at 90°C for 2h; then 7g of crotonaldehyde was added dropwise to the mixture, and the reaction was continued at 90°C for 4h; after the reaction, the mixture was layered, and 2-butanol was recovered from the organic phase , the aqueous phase was distilled under reduced pressure to remove the acid, and the aqueous phase was distilled off with 8wt% 100mL NaHCO 3 The solution was washed and recrystallized with ethanol to obtain high-purity 7-chloroquinalidine with a yield of 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com