Adhesive tape for surface protection of a semiconductor wafer and method of producing a semiconductor wafer using the same

A manufacturing method and semiconductor technology, which can be used in the manufacture of semiconductor/solid-state devices, film/sheet adhesives, adhesives, etc., can solve the problem of radiation curing hindering the embeddedness of the periphery of semiconductor wafers, etc., to prevent wafer damage, restrain Residual glue, the effect of reducing peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

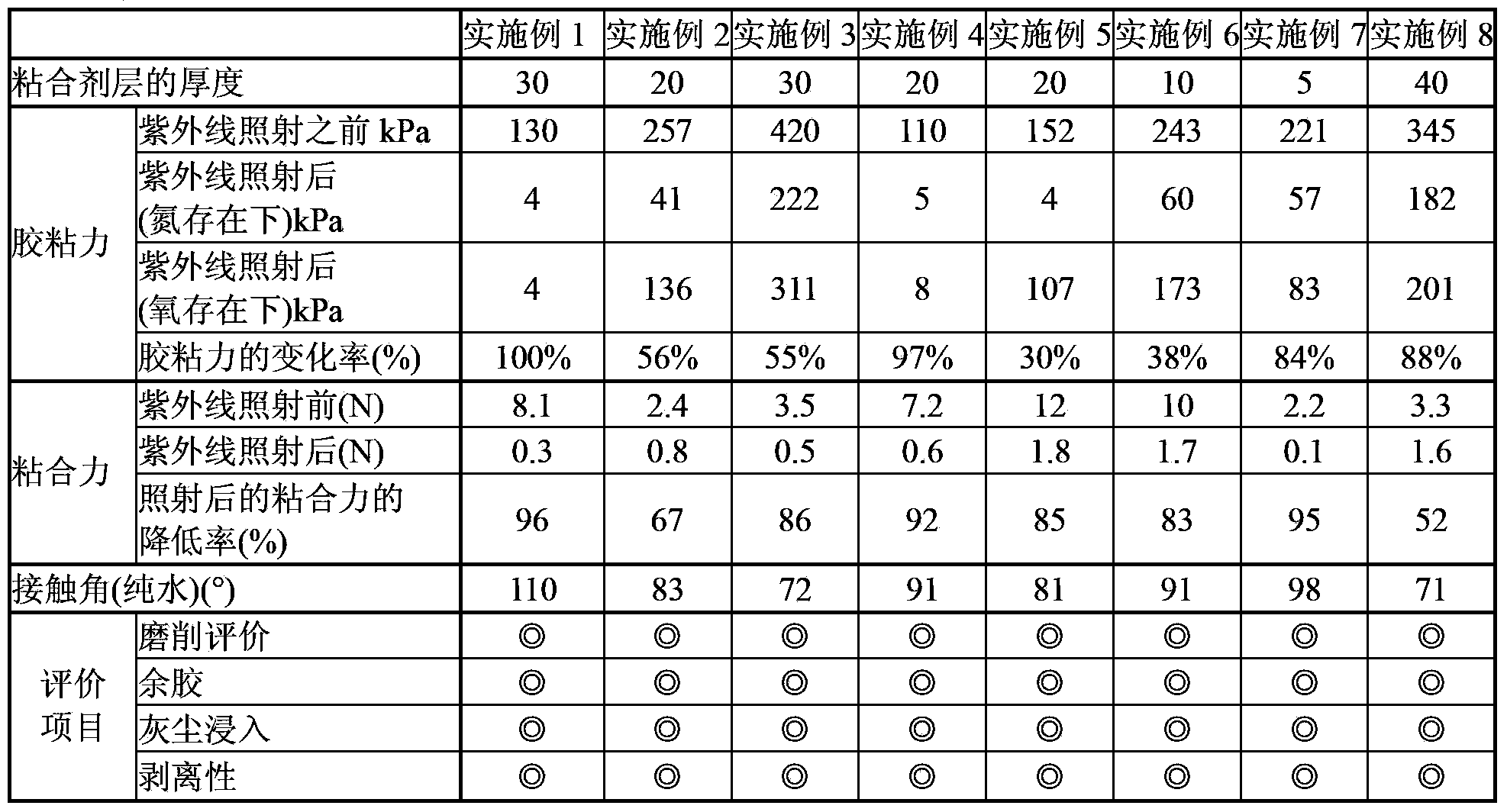

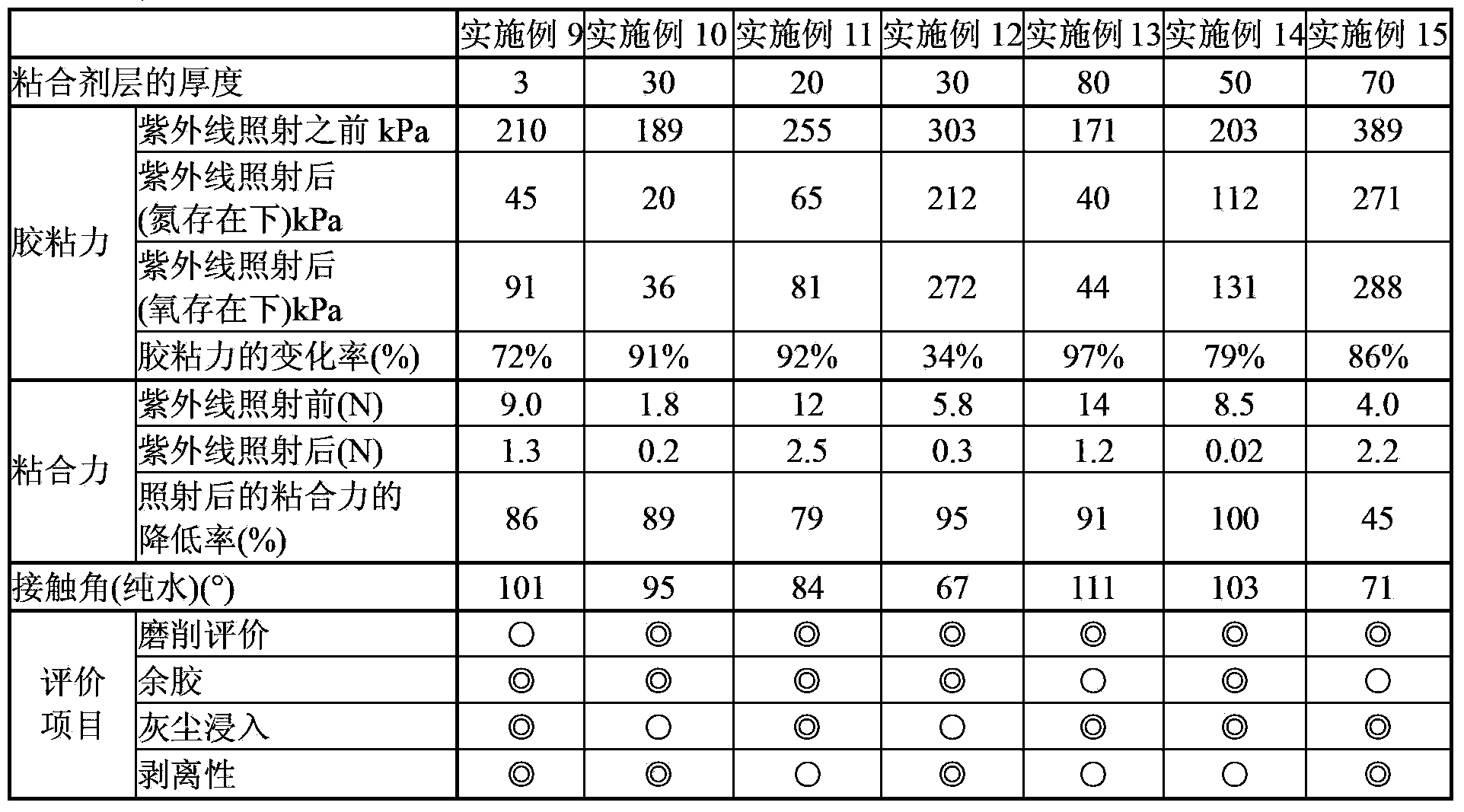

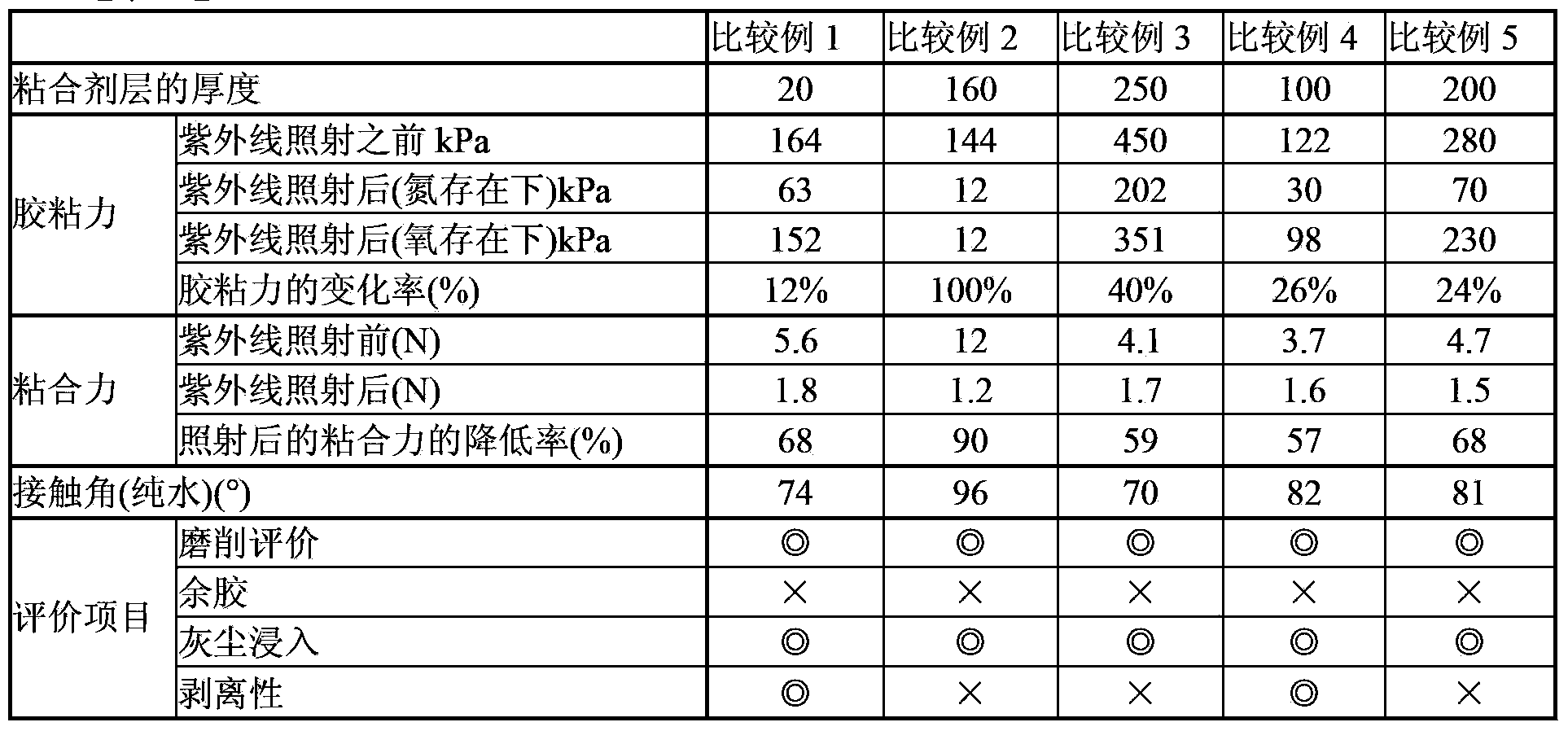

Embodiment 1

[0122] Polymerize 65 parts by mass of 2-ethylhexyl acrylate, 33 parts by mass of 2-hydroxyethyl acrylate, and 2 parts by mass of methacrylic acid in ethyl acetate, and obtain a copolymer having a weight average molecular weight of 800,000 100 parts by mass, 60 parts by mass of ethyl methacrylate-2-isocyanato was added to obtain an acrylic copolymer. 2 parts by mass of an addition-based isocyanate-based crosslinking agent CORONET L (trade name, manufactured by Nippon Polyurethane Co., Ltd.) and a photopolymerization initiator 4,4'-bis(diethylamino) were mixed with the obtained acrylic copolymer. 2 parts by mass of benzophenone were adjusted with ethyl acetate in order to adjust the viscosity to be easy to apply, and an adhesive composition was obtained.

[0123] On a separation plate of polyethylene terephthalate (PET) with a thickness of 25 μm, the adhesive composition is coated with a film thickness of 30 μm after drying, and after drying, it is pasted on a separation plate w...

Embodiment 2

[0125] Polymerize 72 parts by mass of 2-ethylhexyl acrylate, 26 parts by mass of 2-hydroxyethyl acrylate, and 2 parts by mass of methacrylic acid in ethyl acetate, and obtain a copolymer having a weight average molecular weight of 700,000 100 parts by mass, 20 parts by mass of ethyl methacrylate-2-isocyanato was added to obtain an acrylic copolymer. 1.5 parts by mass of an addition-based isocyanate-based crosslinking agent CORONET L (trade name, manufactured by Nippon Polyurethane Co., Ltd.) and a photopolymerization initiator 4,4'-bis(diethylamino) were mixed with the obtained acrylic copolymer. 2 parts by mass of benzophenone were adjusted with ethyl acetate in order to adjust the viscosity to be easy to apply, and an adhesive composition was obtained.

[0126] On a separation plate of polyethylene terephthalate (PET) with a thickness of 25 μm, the adhesive composition is coated with a film thickness of 20 μm after drying, and after drying, it is pasted on a separation plate...

Embodiment 3

[0128] Polymerize 68 parts by mass of 2-ethylhexyl acrylate, 30 parts by mass of 2-hydroxyethyl acrylate, and 2 parts by mass of methacrylic acid in ethyl acetate, and obtain a copolymer having a weight average molecular weight of 800,000 100 parts by mass, 20 parts by mass of ethyl methacrylate-2-isocyanato was added to obtain an acrylic copolymer. 2 parts by mass of an addition-based isocyanate-based crosslinking agent CORONET L (trade name, manufactured by Nippon Polyurethane Co., Ltd.) and a photopolymerization initiator 4,4'-bis(diethylamino) were mixed with the obtained acrylic copolymer. 2 parts by mass of benzophenone were adjusted with ethyl acetate in order to adjust the viscosity to be easy to apply, and an adhesive composition was obtained.

[0129] On a separation plate of polyethylene terephthalate (PET) with a thickness of 25 μm, the adhesive composition is coated with a film thickness of 30 μm after drying, and after drying, it is pasted on a separation plate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com