Lubricating agent and paint made by using same

A technology for lubricants and coatings, applied in pigmented coatings, fiber raw material processing, textiles and papermaking, etc., to achieve the effect of improving smoothness, good stability, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of this lubricant comprises the steps:

[0018] Take stabilizer, polyethylene glycol, viscosity modifier, pH value regulator and bactericide by weighing respectively by above-mentioned parts by weight;

[0019] Add stabilizer, polyethylene glycol, viscosity regulator, pH value regulator and bactericide into water, keep the temperature of the solution system below 80°C and keep stirring to dissolve and disperse the substances evenly.

[0020] The above-mentioned stabilizer, polyethylene glycol, viscosity regulator, pH value regulator and bactericide can be added to the water in a certain order, or they can be added to the water together.

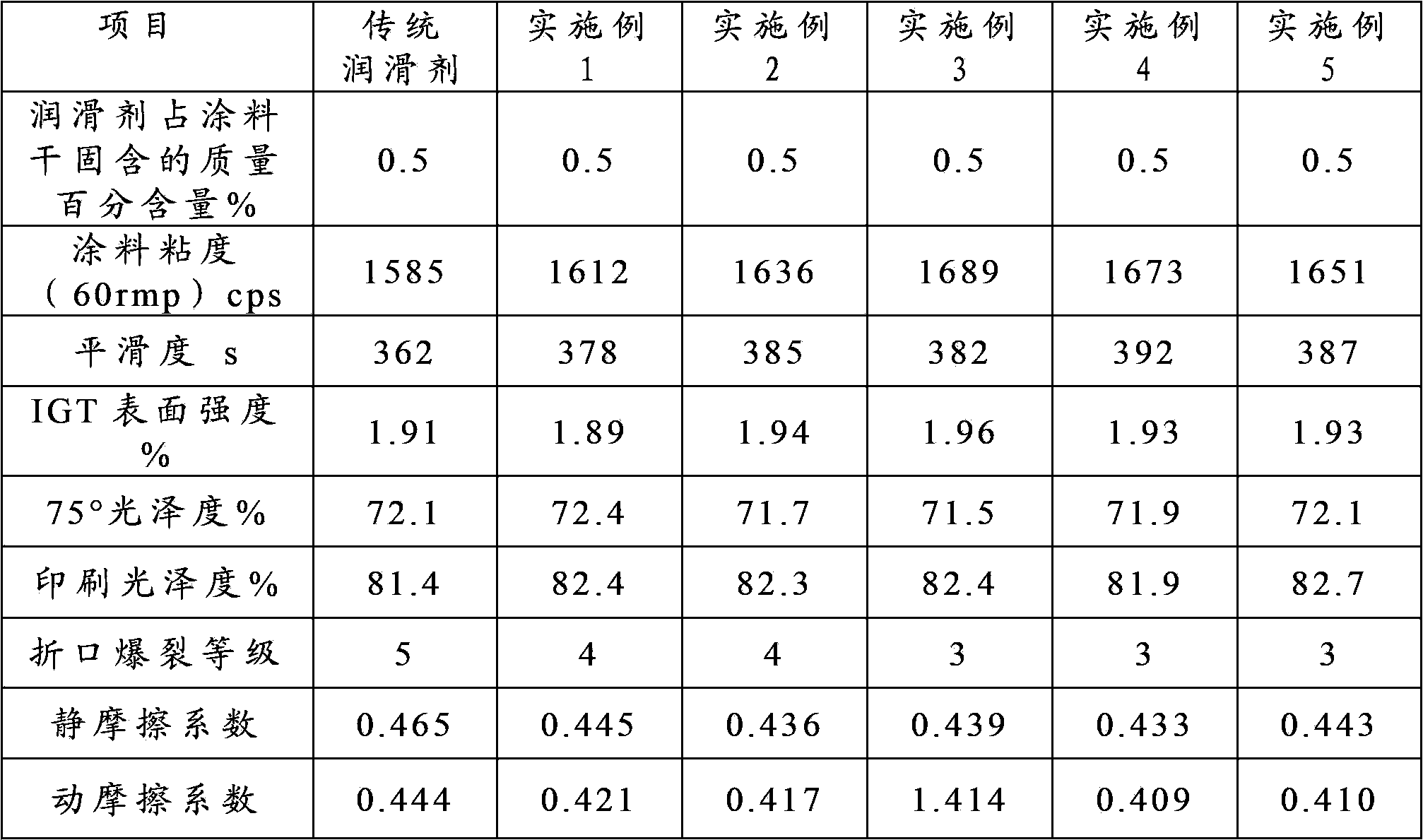

[0021] A coating using the above-mentioned lubricant, the absolute dry mass of the lubricant added is 0.2%-0.8% of the absolute dry mass of the coating, which is within the conventional additive content range of the lubricant.

[0022] The lubricant of the present invention contains polyethylene glycol with good...

Embodiment 1

[0025] Add 100g of water to the flask, raise the temperature to 70°C, add a stabilizer (2.0g formamide + 3.5g triglyceride), stir evenly, add 106g polyethylene glycol 4000, and stir at a low speed at a constant temperature of 80°C until polyethylene glycol The diol is completely dissolved, adding a viscosity modifier (sodium polyacrylate 0.5g), adding a bactericide (0.2g tetrachloroisophthalocyanine), adjusting the pH value to 7.5 with sodium bicarbonate, cooling after stirring, and obtaining the obtained Lubricant mentioned above.

[0026] The Brookfield viscosity (20° C.) of the lubricant prepared in this embodiment is 171 cps, and the solid content is 51.6%.

Embodiment 2

[0028] Add 100g of water to the flask, heat up to 80°C, add a stabilizer (1.5g citric acid + 2.5g triglyceride), stir well, add 94g polyethylene glycol 4000, 7.2g polyethylene glycol 6000, at 65°C Stir at a low speed at a constant temperature until the polyethylene glycol is completely dissolved, add a viscosity modifier (sodium hexametaphosphate 0.5g), add a bactericide (o-chloro-m-cresol 0.2g), adjust the pH value to 7.0 with sodium bicarbonate, and stir After being uniform, the temperature is lowered to obtain the lubricant.

[0029] The Brookfield viscosity (20° C.) of the lubricant prepared in this example was 167 cps, and the solid content was 52.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com