Lithium-ion secondary battery and negative electrode sheet thereof

A technology of secondary battery and negative electrode sheet, which is applied in the direction of secondary battery, battery electrode, non-aqueous electrolyte battery electrode, etc., can solve the problems of increasing battery production cost, low battery coulomb efficiency, and complicated process, such as high temperature curing process of electrode piece, etc. To achieve the effect of reducing production cost, improving bonding effect and reducing production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

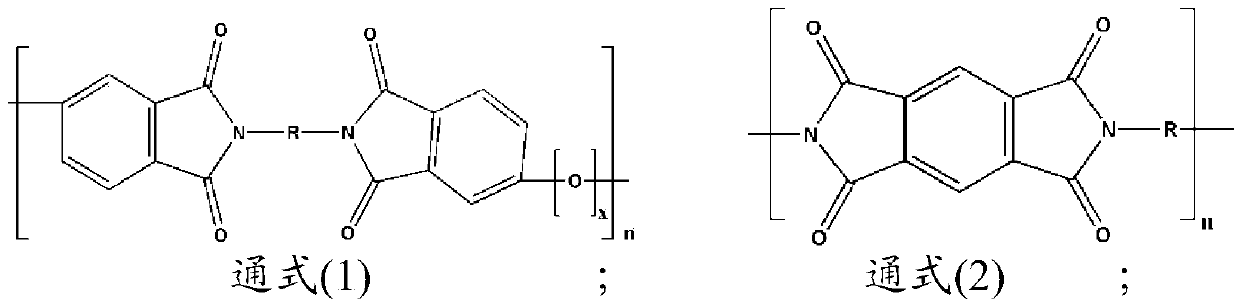

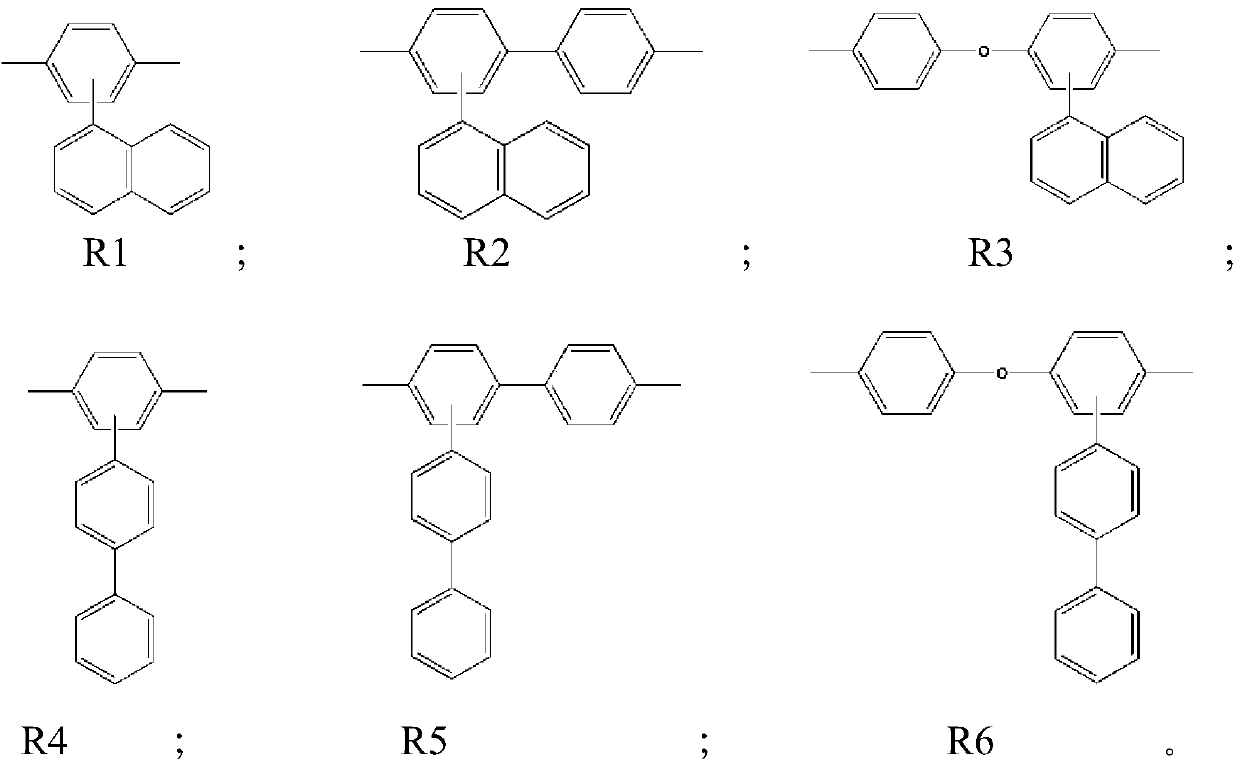

Method used

Image

Examples

Embodiment 1

[0035] Preparation of positive electrode sheet: Lithium cobalt oxide, conductive agent SuperP, and binder PVDF are mixed uniformly at a mass ratio of 96:2.0:2.0 to make a certain viscosity lithium ion secondary battery positive electrode slurry, which is coated on the current collector aluminum foil. Its coating weight is 0.0194g / cm 2 , after drying at 85°C, cold pressing; then trimming, cutting, and slitting, drying at 85°C for 4 hours under vacuum conditions, welding the tabs, and making a lithium-ion secondary battery positive electrode that meets the requirements piece.

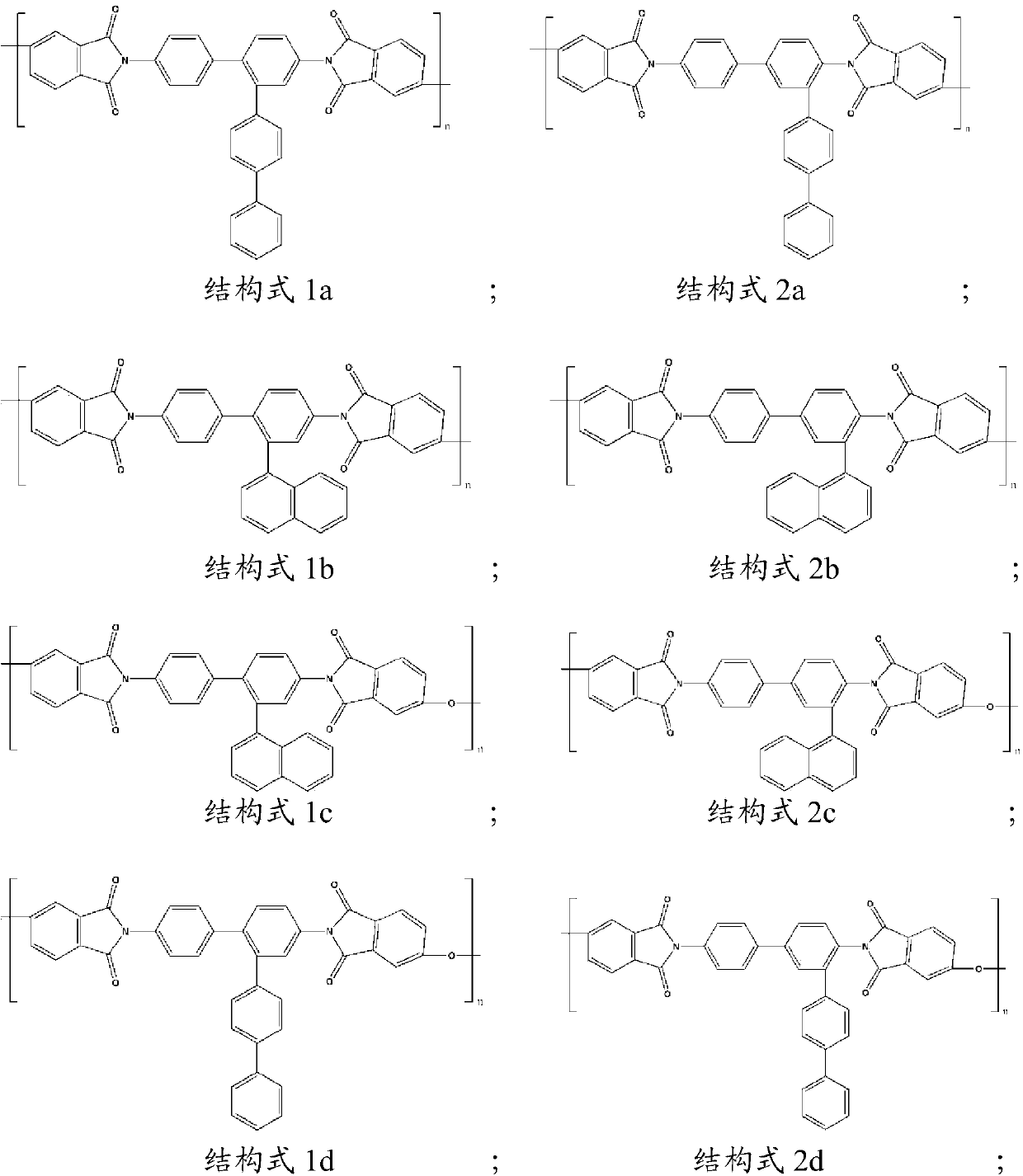

[0036] Preparation of negative electrode sheet: Graphite, silicon, conductive agent SuperP, and soluble polyarimide shown in structural formula 1g were made into slurry at a mass ratio of 85.0:10.0:2.0:3.0, coated on the current collector copper foil and heated at 85 Drying at ℃, the coating weight is 0.0089g / cm 2 ; After trimming, cutting, and slitting, dry at 110° C. for 4 hours under vacuum condition...

Embodiment 2

[0041] A lithium-ion secondary battery was prepared with reference to the method of Example 1, except that the soluble polyarimide shown in structural formula 1a was used instead of the soluble polyarimide in Example 1 when preparing the negative electrode sheet of the lithium-ion secondary battery. The molecular weight of the soluble polyarimide shown in structural formula 1a is 35,000, the tensile strength is 213 MPa, and the elongation at break is 113%.

Embodiment 3

[0043] The lithium ion secondary battery was prepared with reference to the method of Example 1, except that the soluble polyarimide shown in the structural formula 1i was used instead of the soluble polyarimide in Example 1 when preparing the negative electrode sheet of the lithium ion secondary battery. The molecular weight of the soluble polyarimide shown in structural formula 1i is 33,000, the tensile strength is 193 MPa, and the elongation at break is 125%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com