Aluminum alloy non-stick pan with ceramic coating

A technology of ceramic coating and aluminum alloy, which is applied in the field of kitchen utensils, can solve problems such as carcinogenicity, achieve excellent performance, improve heat energy utilization rate and efficiency, and stabilize properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

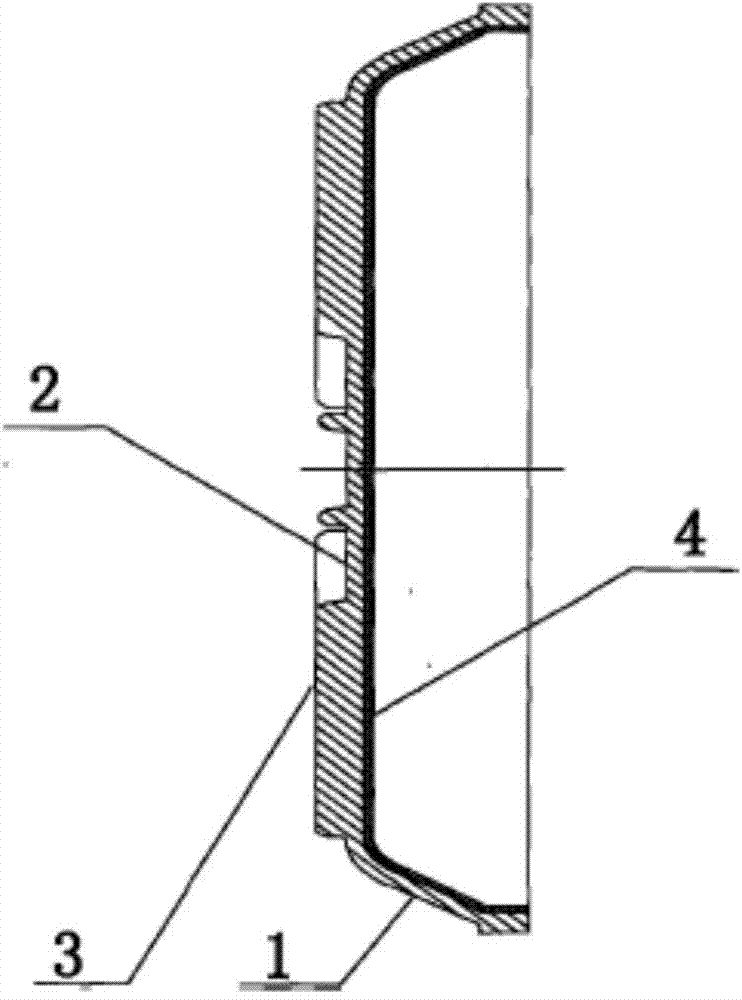

[0027] Such as figure 1 As shown, an aluminum alloy non-stick pan with a ceramic coating includes an aluminum alloy pan body 1, the pan body 1 is a pan bottom 2, and the surface of the pan bottom 2 is formed by pressing and forming the pan body 1 once. Regularly arranged convex bodies 3 are provided with a layer of superhard non-stick silicon ceramic coating layer 4 on the inner surface of the pot body 1. The non-stick silicon ceramic coating layer 4 includes a graphite layer and a cermet coating. The thickness of the graphite layer is 5 ~8 μm, the thickness of the cermet layer is 10-30 μm.

[0028] The above-mentioned cermet layer material includes 70-90% titanium carbide cermet and 10-30% titanium boride.

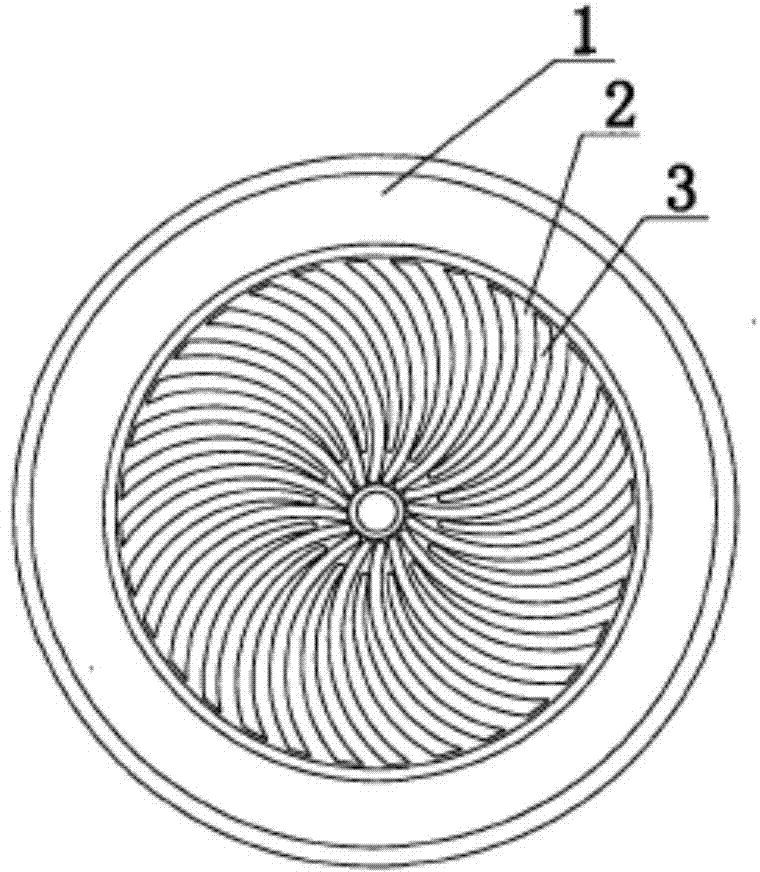

[0029] Such as figure 2 As shown, the above-mentioned convex body 3 is a helical body. This structure can increase the surface area of heat energy at the bottom of the pan 2, reduce heat energy reflection, and make the pot absorb as much heat radiation energy as poss...

Embodiment 2

[0036] Such as figure 1 As shown, an aluminum alloy non-stick pan with a ceramic coating includes an aluminum alloy pan body 1, the pan body 1 is a pan bottom 2, and the surface of the pan bottom 2 is formed by pressing and forming the pan body 1 once. Regularly arranged convex bodies 3 are provided with a layer of superhard non-stick silicon ceramic coating layer 4 on the inner surface of the pot body 1. The non-stick silicon ceramic coating layer 4 includes a graphite layer and a cermet coating. The thickness of the graphite layer is 5 ~8 μm, the thickness of the cermet layer is 10-30 μm.

[0037] The above-mentioned cermet layer material includes 70-90% titanium carbide cermet and 10-30% titanium boride.

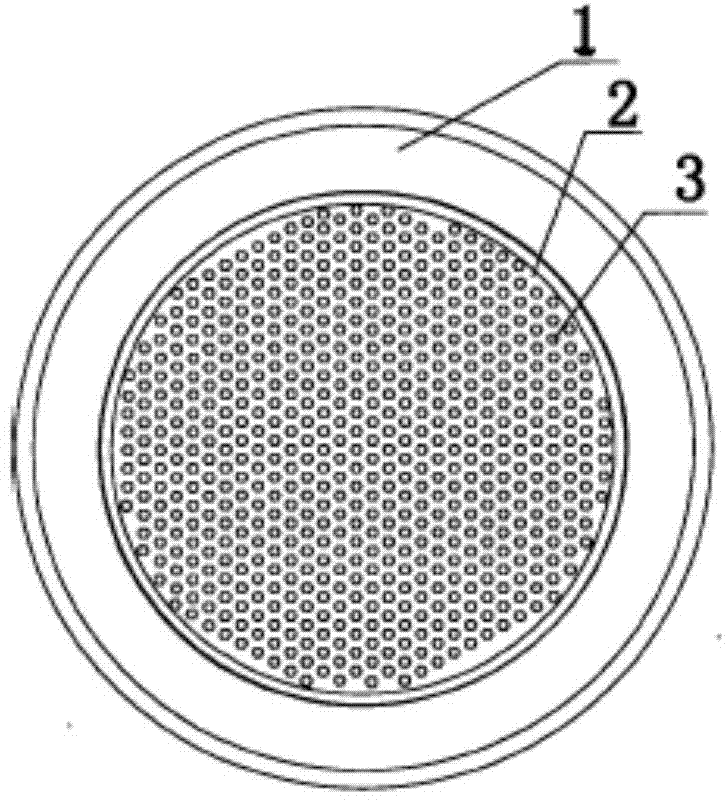

[0038] Such as image 3 As shown, the above-mentioned convex body 3 is a point-shaped body. This structure can increase the surface area of the heat energy of the pan bottom 2 to a certain extent, reduce heat energy reflection, and make the pot absorb as much heat rad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com