Phenylethyl resorcinol hydroxypropyl-beta-cyclodextrin inclusion and preparation method thereof

A technology of phenylethyl resorcinol hydroxypropyl and phenylethyl resorcinol, which is applied in the field of hydroxypropyl-β-cyclodextrin inclusion complex and its preparation, and can solve the problem of poor water solubility and difficulty in direct application , low content of phenethyl resorcinol, etc., to achieve the effects of good stability, increased load content, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of phenethyl resorcinol hydroxypropyl-β-cyclodextrin inclusion compound

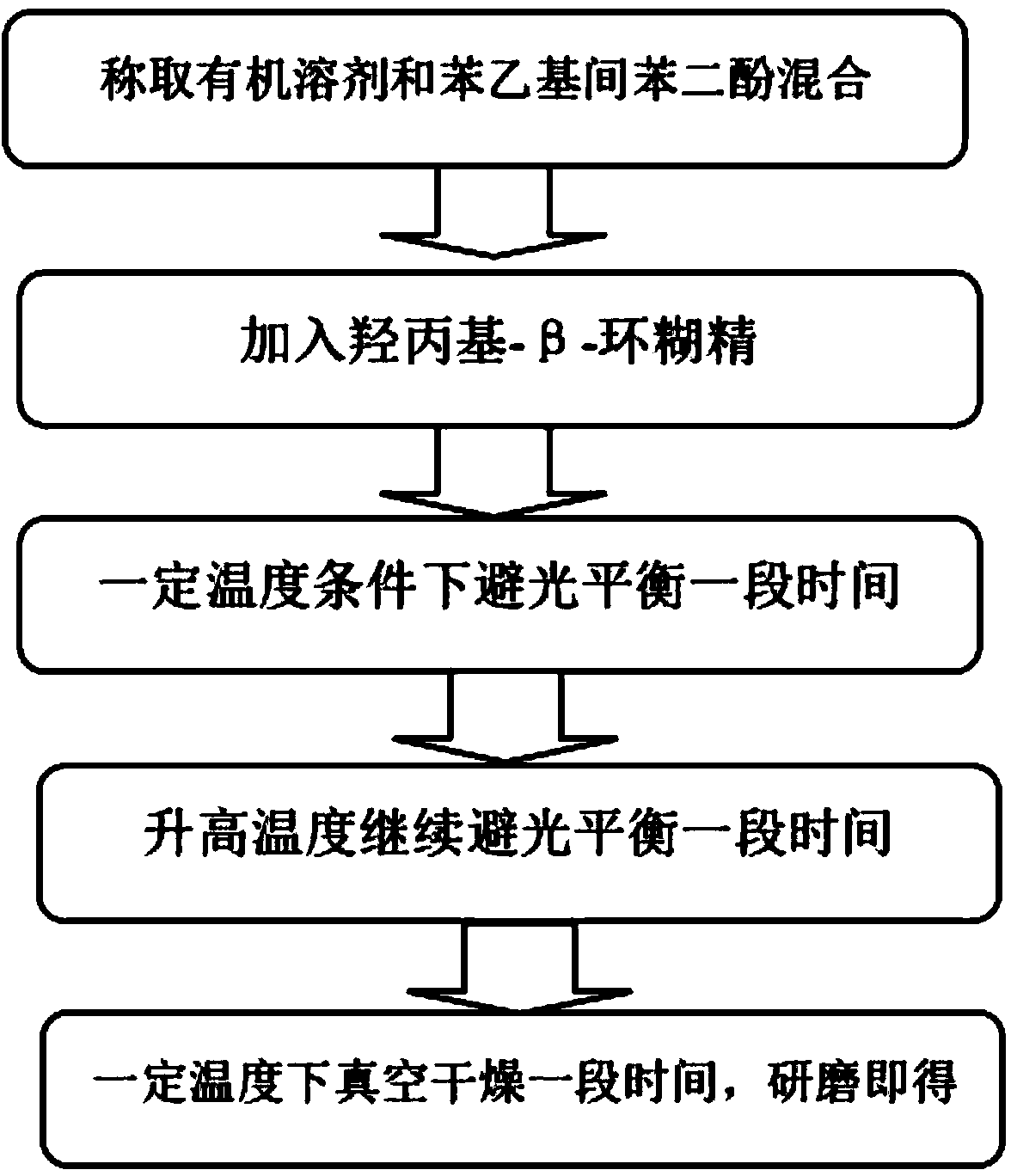

[0026] Such as figure 1 Shown, the preparation steps of this embodiment are as follows:

[0027] 1. Weigh 0.2g of phenylethyl resorcinol, dissolve in 10g of ethanol, shake and mix until clear;

[0028] 2. Then weigh 10g of hydroxypropyl-β-cyclodextrin and add it to the ethanol solution of phenylethyl resorcinol, and stir until uniform;

[0029] 3. Equilibrate in the dark for 20 minutes at 28°C;

[0030] 4. Then equilibrate at 50°C in the dark for 60 minutes;

[0031] 5. Put the above mixture into a disc, and dry it in vacuum at 60°C for 120 minutes to obtain a white loose porous solid, which is ground to powder;

[0032] 6. Store the obtained phenylethylresorcinol hydroxypropyl-β-cyclodextrin inclusion complex in a dry dish away from light, and the inclusion rate is 97.5±1.5% as determined by high performance liquid chromatography.

Embodiment 2

[0033] Example 2 Preparation of phenylethyl resorcinol hydroxypropyl-β-cyclodextrin inclusion compound

[0034] Such as figure 1 Shown, the preparation steps of this embodiment are as follows:

[0035] 1. Weigh 0.3g of phenylethyl resorcinol, dissolve in 10g of 1,2-propanediol, shake and mix until clear;

[0036] 2. Then weigh 12g of hydroxypropyl-β-cyclodextrin and add it to the phenylethyl resorcinol 1,2-propanediol solution, and stir until uniform;

[0037] 3. Equilibrate in the dark for 30 minutes at 28°C;

[0038] 4. Then equilibrate at 60°C in the dark for 60 minutes;

[0039] 5. Put the above mixture into a disc, and dry it in vacuum at 60°C for 60 minutes to obtain a white loose porous solid, which is ground to powder;

[0040] 6. Store the obtained phenylethylresorcinol hydroxypropyl-β-cyclodextrin inclusion complex in a dry dish away from light, and the inclusion rate is 81.8±2.9% as determined by high performance liquid chromatography.

Embodiment 3

[0041] Example 3 Preparation of phenethyl resorcinol hydroxypropyl-β-cyclodextrin inclusion compound

[0042] Such as figure 1 Shown, the preparation steps of this embodiment are as follows:

[0043] 1. Weigh 0.5g of phenylethyl resorcinol, dissolve in 10g of tert-butanol, shake and mix until clear;

[0044] 2. Then weigh 15g of hydroxypropyl-β-cyclodextrin and add it to the phenylethyl resorcinol tert-butanol solution, and stir until uniform;

[0045] 3. Equilibrate in the dark for 30 minutes at 28°C;

[0046] 4. Then equilibrate at 50°C in the dark for 100 minutes;

[0047] 5. Put the above mixture into a disc, and dry it in vacuum at 60°C for 150 minutes to obtain a white loose porous solid, which is ground to powder;

[0048] 6. Store the obtained phenylethylresorcinol hydroxypropyl-β-cyclodextrin inclusion complex in a dry dish away from light, and determine by high performance liquid chromatography that the inclusion rate is 91.6±2.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com