A system and method for repairing and remanufacturing a cylinder block of a large-diameter hydraulic cylinder

A hydraulic cylinder and large-diameter technology, which is applied in the field of equipment repair and remanufacturing, can solve the problems of difficult formation of inner surface cladding layer, large difference between the outer edge and inner edge of the light spot, and high cost, so as to achieve good economic applicability and improve stress resistance Corrosion and anti-wear performance, effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

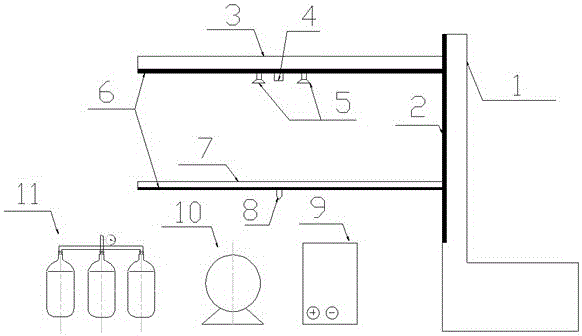

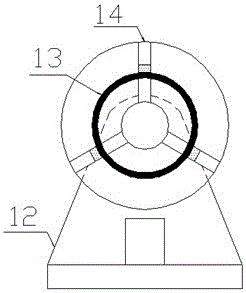

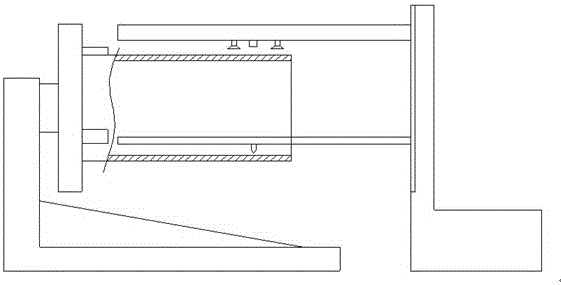

Method used

Image

Examples

Embodiment 1

[0047] The inner diameter is Ф280mm, the maximum stress corrosion depth is 1mm, and the maximum expansion cylinder is 5mm (the size of the expansion cylinder is the diameter of the expansion cylinder, which is the diameter difference of the inner wall before and after the expansion cylinder of the cylinder body. For the 5mm expansion cylinder, the deformation deviation of the inner wall on one side is 2.5mm. The same below) to repair and remanufacture the large-diameter hydraulic cylinder block, including the following steps:

[0048] (1) The hydraulic cylinder is heated and degreased, and the heating is carried out in a box-type oven with a heating temperature of 100°C and a heat preservation of 1.5 hours;

[0049] (2) Use a water-soluble coloring flaw detection agent for coloring flaw detection on the inner surface to ensure that there are no buried defects on the inner surface of the oil tank;

[0050] (3) Sandblast the inner surface of the cylinder after the treatment in s...

Embodiment 2

[0058] The repair and remanufacturing of large-diameter hydraulic cylinders with an inner diameter of Ф320mm, a maximum stress corrosion depth of 1mm, and a maximum cylinder expansion of 7mm (the maximum deviation of one-sided inner wall size deformation is 3.5mm) includes the following steps:

[0059] (1) Heat and degrease the hydraulic cylinder in a box-type oven at a heating temperature of 120°C for 1 hour;

[0060] (2) Use a water-soluble coloring flaw detection agent for coloring flaw detection on the inner surface to ensure that there are no buried defects on the inner surface of the oil tank;

[0061] (3) Sandblast the inner surface of the cylinder after the treatment in step (2), the sand material is 60 mesh brown corundum, and the sandblasting air pressure is 0.65Mpa;

[0062] (4) Perform automatic argon arc welding on the inner surface of the oil cylinder after step (3). The welding wire is H12Cr24Ni13Si, the diameter of the welding wire is 1.6mm, the wire feeding sp...

Embodiment 3

[0069] The repair and remanufacturing of large-diameter hydraulic cylinders with an inner diameter of Ф360mm, a maximum stress corrosion depth of 1.5mm, and a maximum cylinder expansion of 8mm (the maximum deviation of dimensional deformation of the inner wall on one side is 4mm) includes the following steps:

[0070] (1) Heat and degrease the hydraulic cylinder in a box-type oven at a heating temperature of 150°C for 1 hour;

[0071] (2) Use a water-soluble coloring flaw detection agent for coloring flaw detection on the inner surface to ensure that there are no buried defects on the inner surface of the oil tank;

[0072] (3) Sandblast the inner surface of the cylinder after the treatment in step (2), the sand material is 70 mesh brown corundum, and the sandblasting air pressure is 0.75Mpa;

[0073] (4) Perform automatic argon arc welding on the inner surface of the oil cylinder after step (3). The welding wire is H12Cr24Ni13Si, the diameter of the welding wire is 1.6mm, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com