Processing equipment capable of achieving continuous sterilization and water bath cooling

A technology of processing equipment and water bath, which is applied in the field of continuous sterilization and water bath cooling processing equipment, can solve the problem of inability to achieve product quality consistency, unfavorable to maintain physical indicators of objects to be sterilized, damage to nutrients and food color, aroma and flavor. and other problems, to achieve good economic benefits and market prospects, realize automatic continuous processing production lines, and improve the effect of processing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]

[0043] The present invention is not limited to the described embodiment, and the working process of the invention is described below by means of the accompanying drawings.

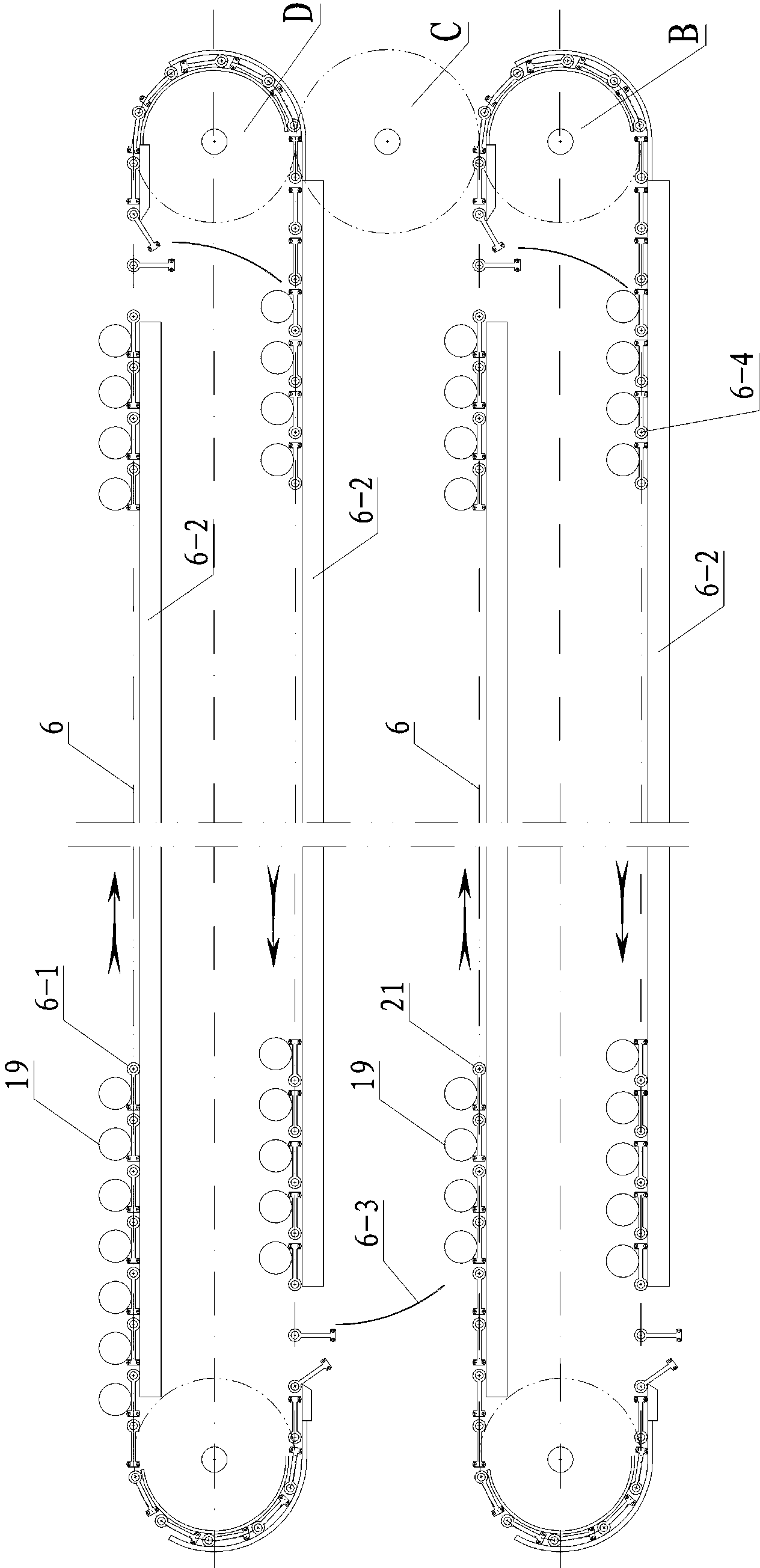

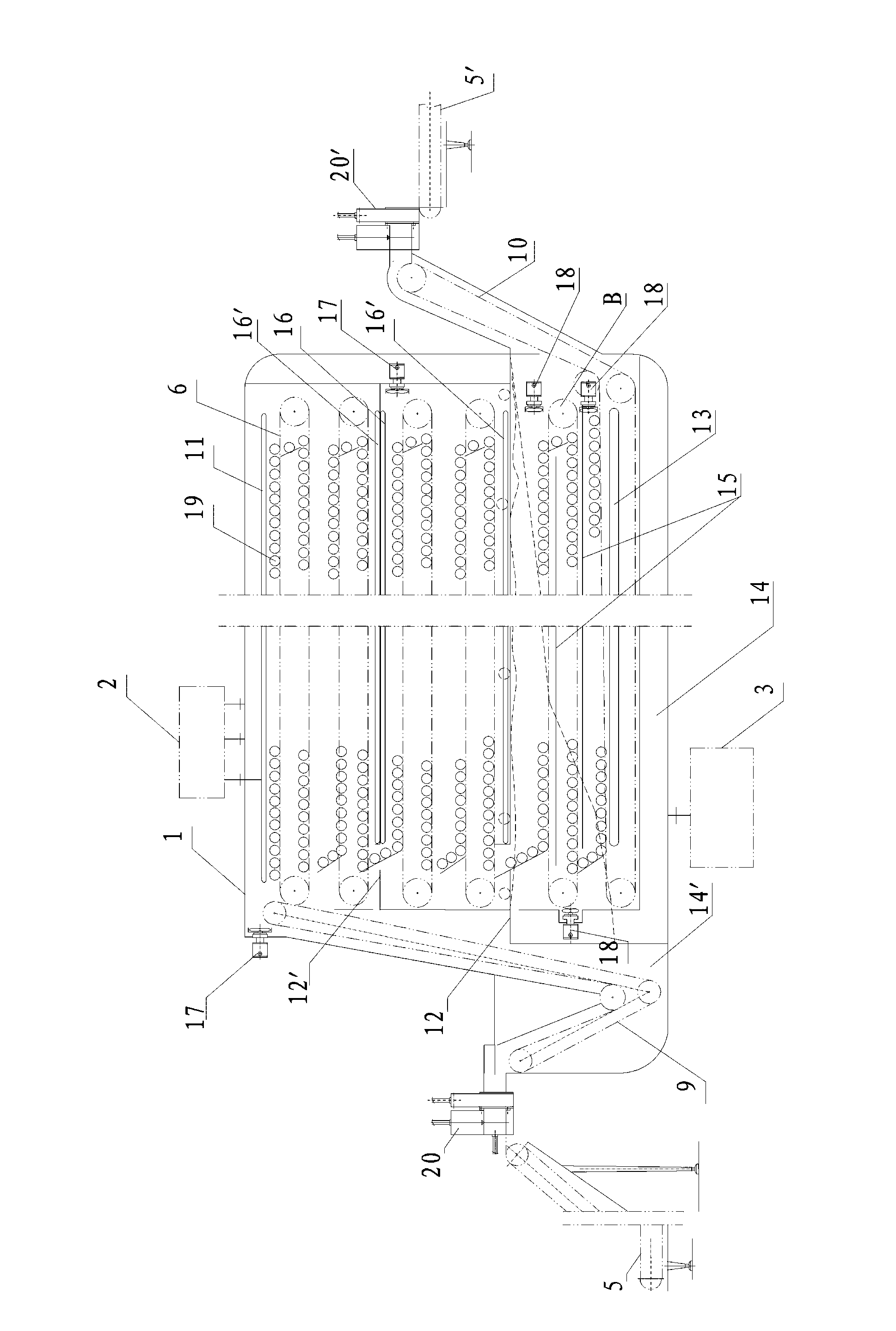

[0044] Such as figure 1 Shown: If the processed items are canned, bottled canned food, beer, PE bottled vegetable protein drinks, dairy products and other large packaging items, they can be directly entered into the sterilization chamber in a horizontal manner for sterilization processing. If the processed items are Small items such as ham sausages, soft-packed beverages, soft-packed dairy products and soft-packed medicines can be loaded into one basket, and the packages can be made into round or square shapes.

[0045]

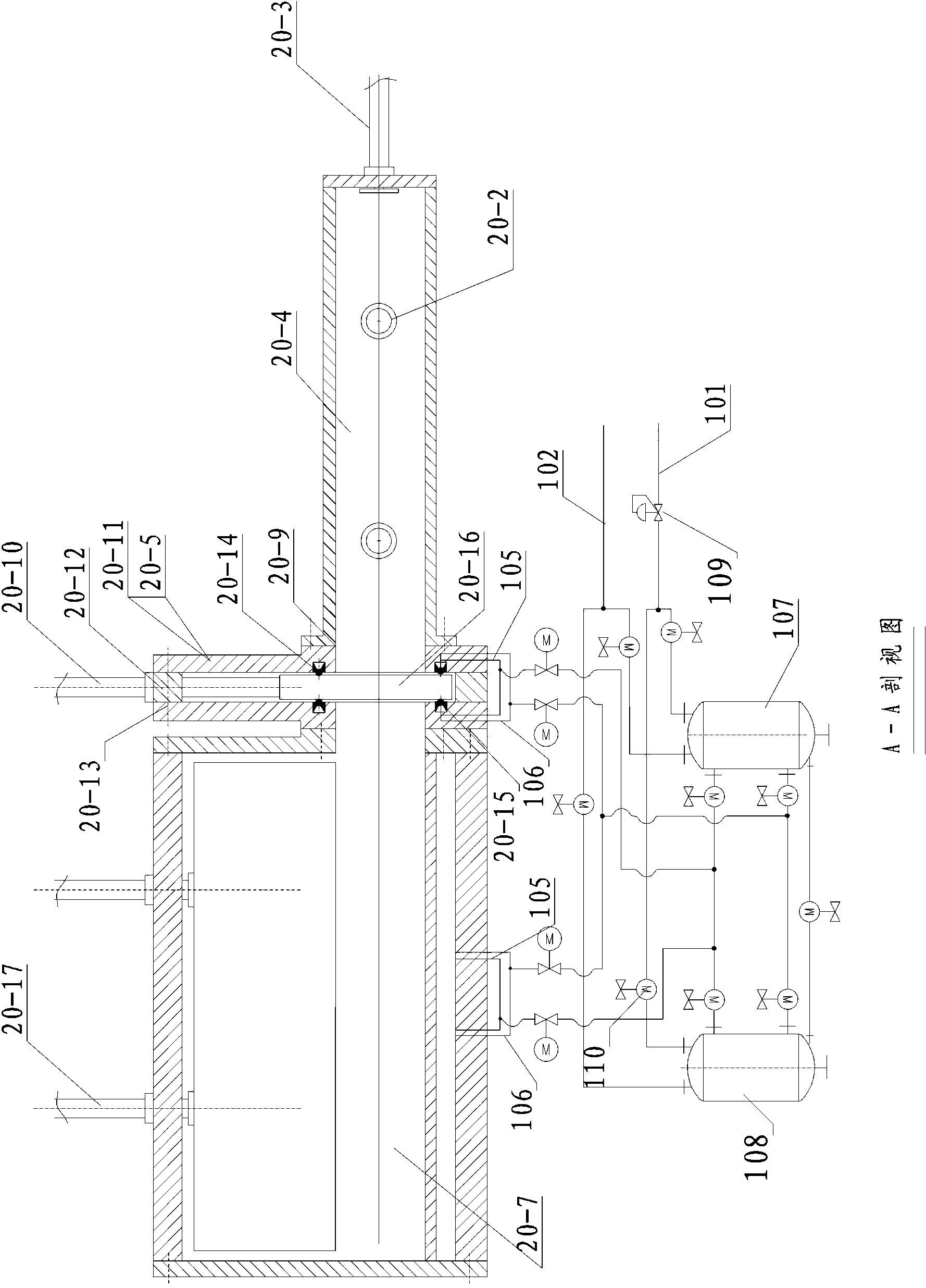

[0046] The working process of the feed sealing device 20 is: the processed products 19 to be sterilized are transported from the production line, and the soft-packed items run on the loading platform 20-1 through the loading basket on the conveyor chain of the loading station,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com