Porous carbonate and porous oxide preparation methods

A technology of porous oxides and carbonates, which is applied in the preparation of carbonates/acid carbonates, preparation of oxides/hydroxides, chemical instruments and methods, etc., which can solve the problems of high production costs and experimental conditions High, complex experimental process and other issues, to achieve the effects of reduced production costs, low requirements for the experimental environment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

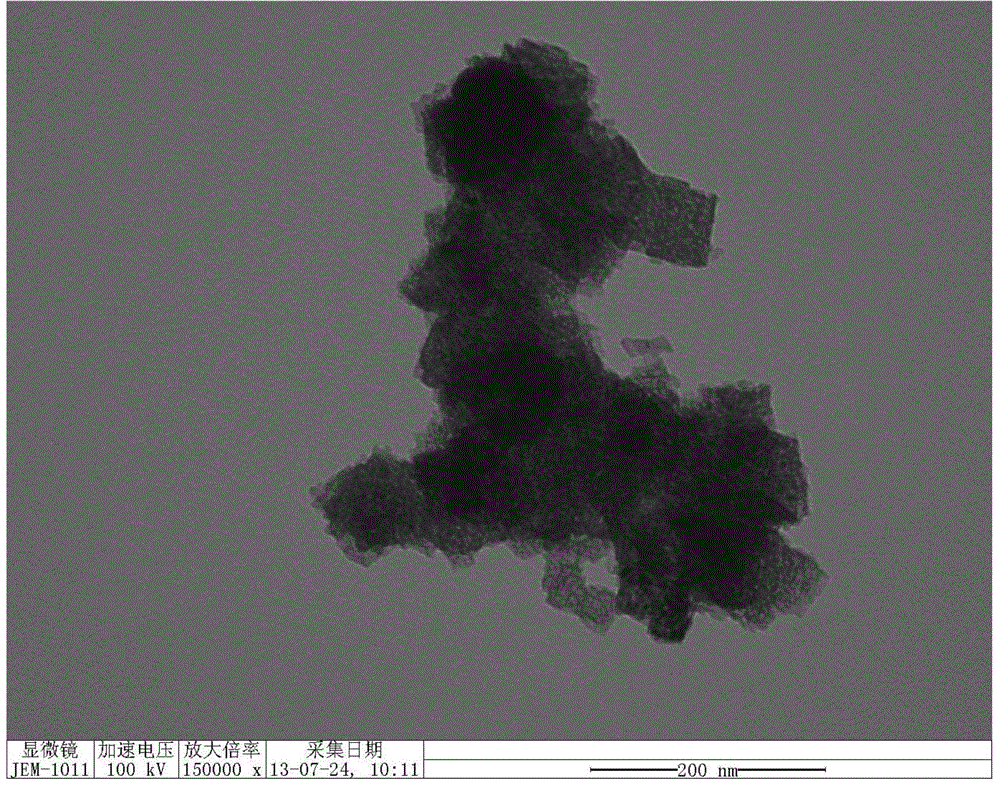

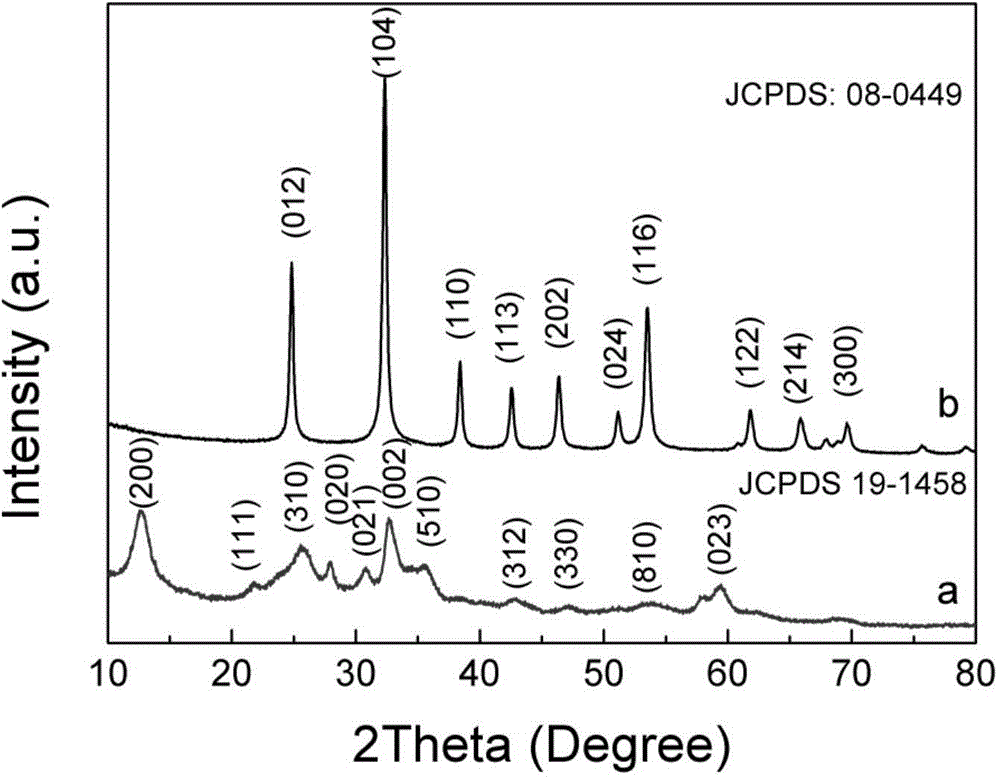

[0028] Weigh zinc sulfate heptahydrate and precipitating agent ammonium bicarbonate according to the molar ratio of 1:2, add pore-forming agent PEG with 2 times the quality of zinc sulfate heptahydrate and mix evenly with it, fully grind for 40 minutes and let it stand for a sufficient time (4 hours ), taken out, suction filtered, washed to remove the pore-forming agent, and dried to obtain porous zinc carbonate. Roast a certain amount of porous zinc carbonate at a temperature of 600°C for 2 hours to obtain porous zinc oxide.

Embodiment 2

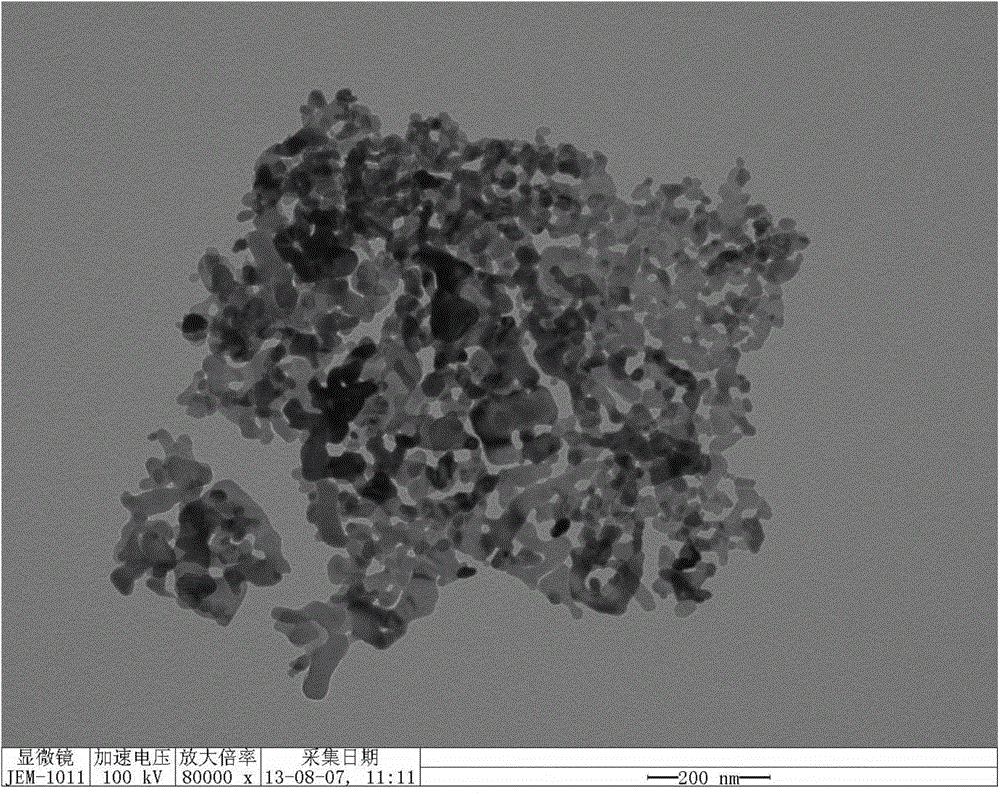

[0030] Weigh manganese sulfate heptahydrate and precipitating agent ammonium bicarbonate according to the molar ratio of 1:2, add pore-forming agent PEG with 5 times the quality of manganese sulfate heptahydrate and mix evenly with it, fully grind for 40 minutes and let stand for enough time (4 hours ), taken out, suction filtered, washed to remove the pore-forming agent, and dried to obtain porous zinc carbonate. Roast a certain amount of porous manganese carbonate at a temperature of 600°C for 2 hours to obtain porous manganese oxide.

Embodiment 3

[0032] First, weigh the mixture of zinc sulfate heptahydrate and manganese sulfate according to the molar ratio of 1:2, then weigh the precipitant ammonium bicarbonate with 4 times the quality of the sulfate, add an appropriate amount of pore-forming agent PEG and mix it evenly, fully grind (40 Minutes) After standing for a sufficient time (4 hours), take it out, filter with suction, wash to remove the pore-forming agent, and dry to obtain a mixture of porous zinc carbonate and manganese carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com