Fabrication method of monolithic integrated chip of laser array and combiner

A laser array, monolithic integration technology, applied in lasers, laser components, semiconductor lasers, etc., can solve the problems of reducing the yield of device manufacturing, increasing the complexity of device manufacturing, etc., to simplify the device manufacturing process and reduce optical diffraction loss. , the effect of reducing the size of the combiner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

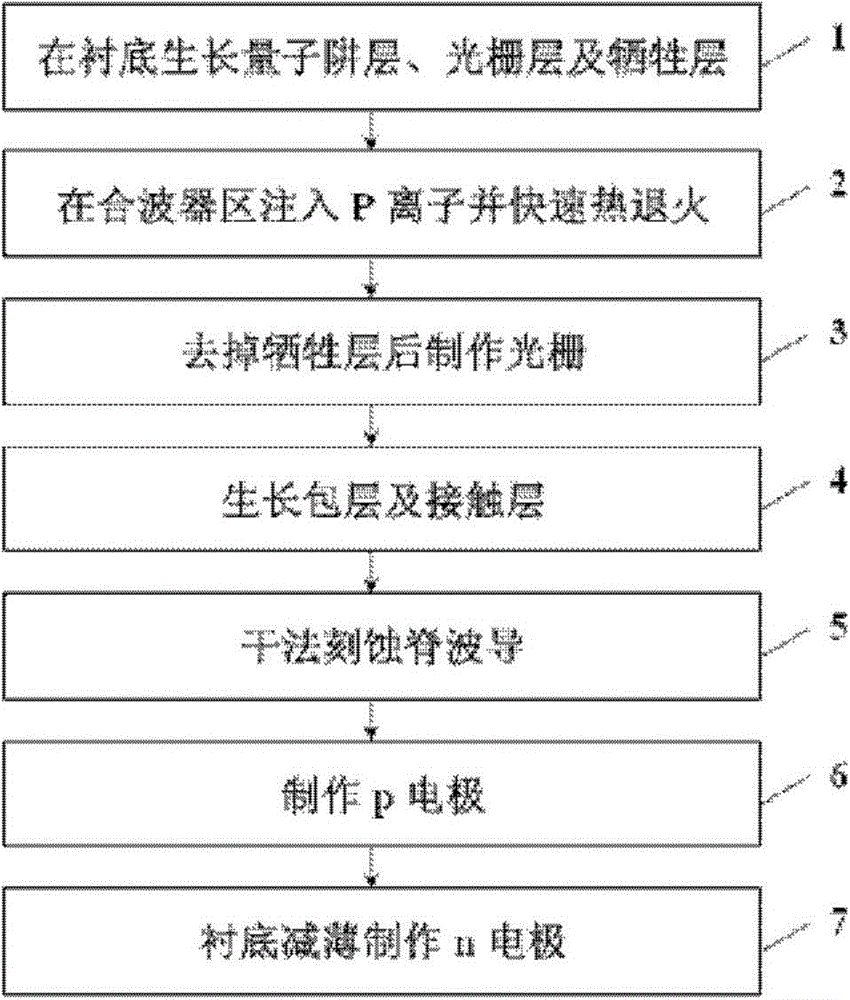

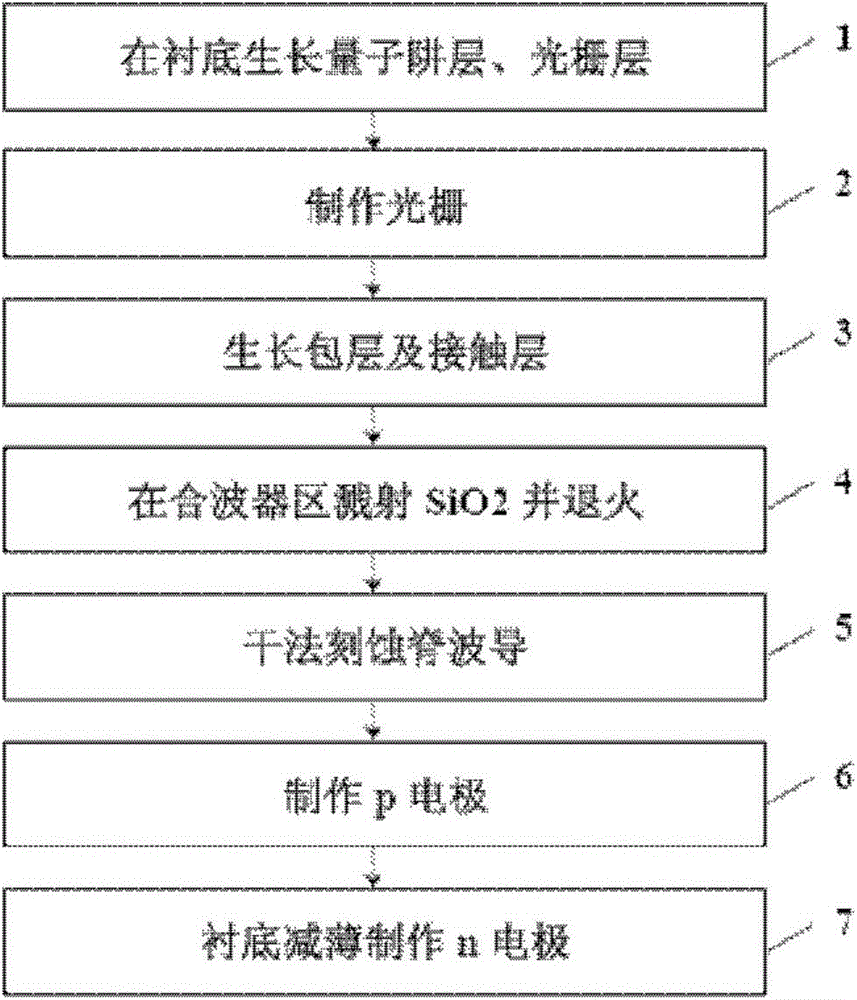

[0026] see figure 1 , is the first embodiment of the present invention, with reference to Figure 3 to Figure 8 As shown, the present invention provides a method for manufacturing a monolithic integrated chip of a laser array and a multiplexer, comprising the following steps:

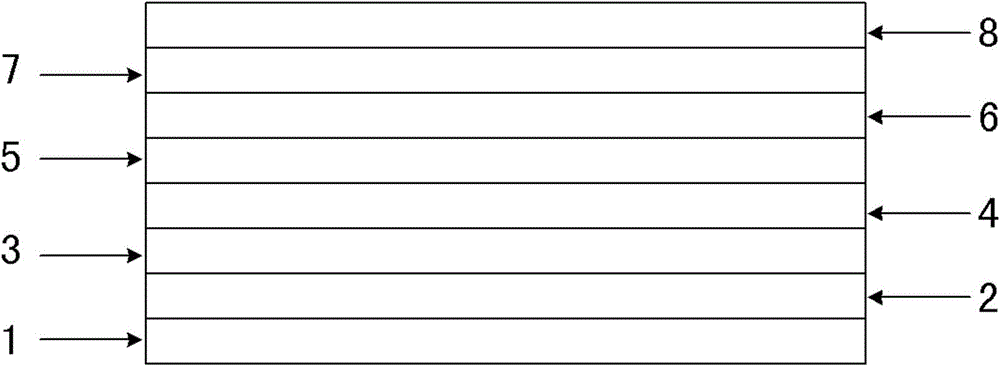

[0027] Step 1: On the n-type InP substrate 1, grow n-type InP buffer layer 2, n-type AlGaInAs cladding layer 3, AlGaInAs multi-quantum well layer 4, p-type AlGaInAs cladding layer 5, InP spacer layer 6, and InGaAsP grating layer 7 sequentially , InP sacrificial layer 8, forming the substrate, such as image 3 , one side of the substrate is the active region A, and the other side is the combiner region D, such as Figure 4 . The AlGaInAs multi-quantum well layer 4 includes more than two AlGaInAs quantum wells and two upper and lower AlGaInAs refractive index gradient layers. There may be no InP spacer layer 6 in the device;

[0028] Step 2: Implant P ions into the InP sacrificial layer 8 in the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com