A breeding pond bottom treatment system

A pond and bottom material technology, which is applied in the field of breeding pond bottom material treatment system, can solve the problems such as difficult bottom treatment, and achieve the effects of controllable regulation, low treatment efficiency, and reduced water treatment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

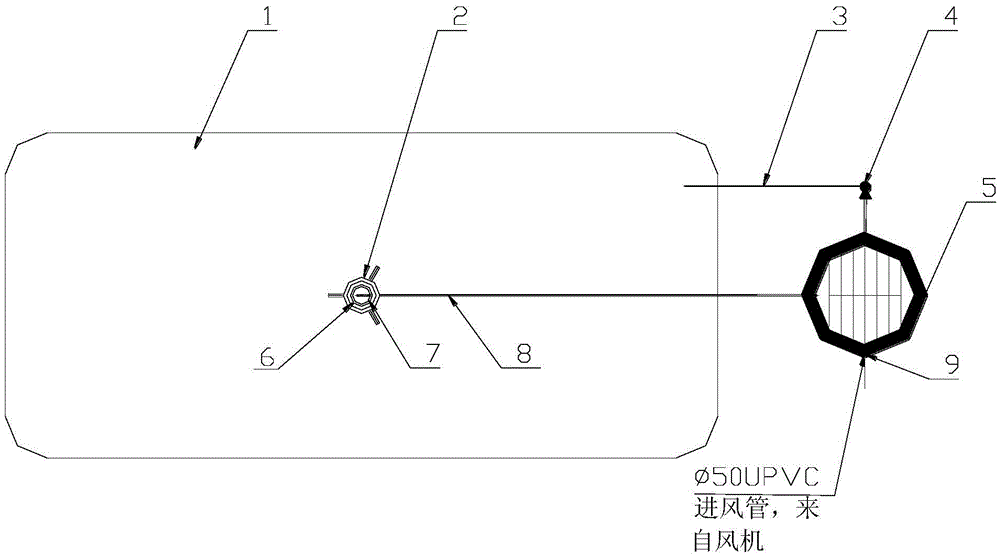

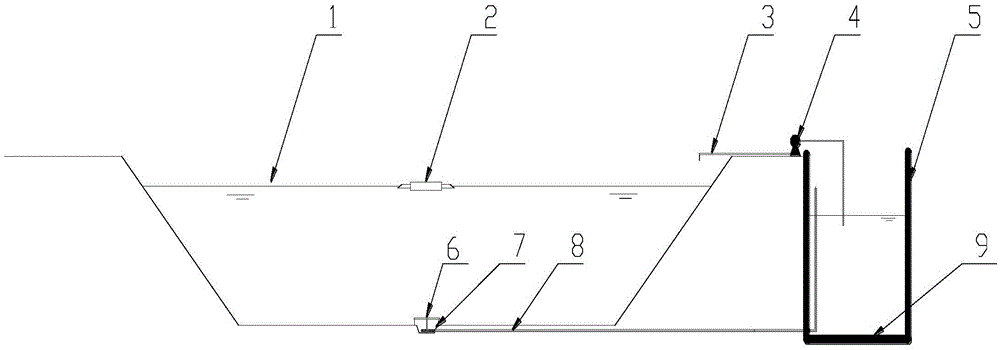

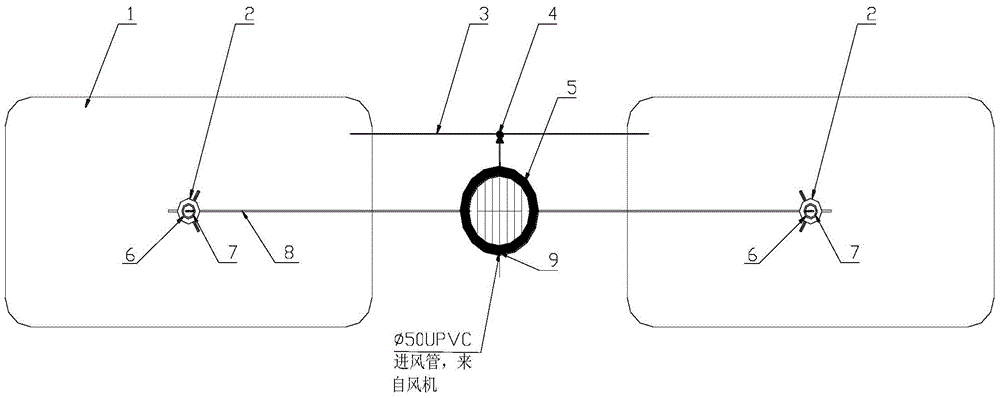

[0019] The pond bottom material collection and purification system of the present invention is composed of a square or circular culture pond, a surge machine (sewage collection), a sewage collection pit, a protective cover plate, a sewage collection pipe, and a sequencing batch reactor activated sludge process (sequencingbatchreactoractivatedsludgeprocess, It is composed of SBR pool for short), water delivery equipment and return water pipeline. The aquaculture pond is generally 3-7 acres, and a 1.1KW surge machine is installed in the center of the pond; a sewage collection pit with a diameter of about 0.5-2.0m is installed at the bottom of the pool directly below the wave machine, and the depth is about 0.5m; the top of the pit A circular protective cover plate is installed slightly higher than the surrounding pond bottom 5-10cm. The diameter of the cover plate is slightly larger than the diameter of the sewage collection pit; a UPVC pipe or corrugated pipe with a diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com