Astragalus extractive grading preparation method

An astragalus extract and an astragalus extract technology are applied in the field of preparing the astragalus extract by using subcritical fluid classification, which can solve the problems of high manufacturing and operating costs, difficult industrial mass production, large ethanol consumption and the like, and achieves simplified production process, The effect of less impurities and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

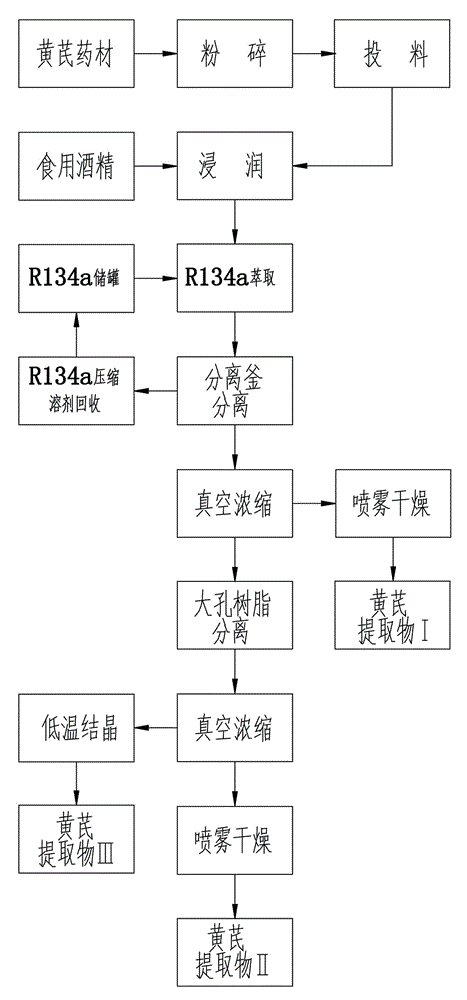

Method used

Image

Examples

Embodiment 1

[0059] (1) Raw material treatment: take 100kg of dried Astragalus medicinal material, detect that the content of astragaloside IV is 0.4%, crush it into 30-60 mesh coarse powder, put it into a 100-mesh filter bag, and then put the filter bag into subcritical In the material column of the extraction kettle;

[0060] (2) Raw material infiltration: Add 50L of edible alcohol with a volume fraction ≥ 95% in the extraction kettle as an entrainer, and infiltrate for 30 minutes at a temperature of 30°C;

[0061] (3) Subcritical extraction: Add 500L 1,1,1,2-tetrafluoroethane into the extraction kettle as the extraction agent, extract for 30 minutes at a pressure of 1Mpa and a temperature of 40°C, and put the extract into the separation kettle In the process, under the pressure of 0.04Mpa, the extractant is evaporated and recovered for mechanical use, and the remaining liquid is the Astragalus extract; the above extraction process is repeated 4 times, and the Astragalus extract is combi...

Embodiment 2

[0078] (1) Raw material treatment: Take 100kg of dried Astragalus medicinal material, detect that the content of astragaloside IV is 0.4%, grind it into coarse powder of 10-60 mesh, put it into a 100-mesh filter bag, and then put the filter bag into subcritical In the material column of the extraction kettle;

[0079] (2) Raw material infiltration: Add 20L of edible alcohol with a volume fraction ≥ 95% in the extraction kettle as an entrainer, and infiltrate at a temperature of 50°C for 60 minutes;

[0080] (3) Subcritical extraction: Add 600L 1,1,1,2-tetrafluoroethane into the extraction kettle as the extractant, extract for 40 minutes at a pressure of 1.2Mpa and a temperature of 40°C, and put the extract into the separation In the kettle, under the pressure of 0.04Mpa, the extractant was evaporated and recovered for mechanical use, and the remaining liquid was the Astragalus extract; the above extraction process was repeated 3 times, and the Astragalus extract was combined e...

Embodiment 3

[0095] (1) Raw material treatment: Take 100kg of dried Astragalus medicinal material, detect that the content of astragaloside IV is 0.4%, grind it into coarse powder of 10-60 mesh, put it into a 100-mesh filter bag, and then put the filter bag into subcritical In the material column of the extraction kettle;

[0096] (2) Raw material infiltration: add 150L of edible alcohol with a volume fraction ≥ 95% in the extraction kettle as an entrainer, and infiltrate at a temperature of 30°C for 20 minutes;

[0097] (3) Subcritical extraction: add 400L 1,1,1,2-tetrafluoroethane into the extraction kettle as the extraction agent, extract for 40 minutes at a pressure of 0.8Mpa and a temperature of 40°C, and put the extract into the separation In the kettle, under the pressure of 0.08Mpa, the extractant is evaporated and recovered for mechanical use, and the remaining liquid is the extract of Astragalus; repeat the above extraction process 5 times, and combine the extract of Astragalus e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com