Method for recycling valuable elements from blast furnace flocculated dust

A valuable element, blast furnace technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of poor efficiency and high cost, and achieve the effect of low production cost, reduced loss, and good comprehensive recovery and utilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

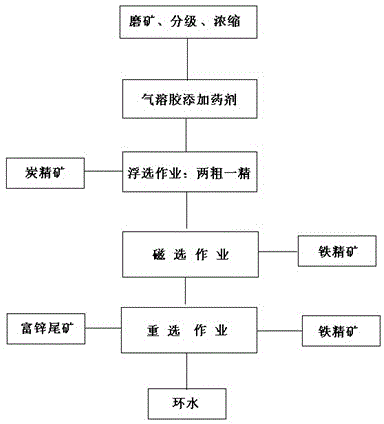

[0022] This embodiment discloses a method for recovering valuable elements from blast furnace flocculation dust and sludge. The method is a process for processing low-grade blast furnace flocculation dust and sludge containing 2-8% zinc by mineral processing, and adopts flotation-magnetic separation-gravity Choose the combined process method to recover the valuable elements. For specific steps, see figure 1 :

[0023] A. Grinding, grading, concentrating

[0024] The blast furnace ironmaking bag ash (easy to sort) is first ground and classified with a fine sieve. The fineness of the product under the sieve after classification is between -200 mesh and 75-85%. The product on the sieve is concentrated and ground before returning to the classification operation . Due to its fineness, blast furnace dedusting sludge directly enters the fine sieve for classification, and the products on the sieve are returned to grinding;

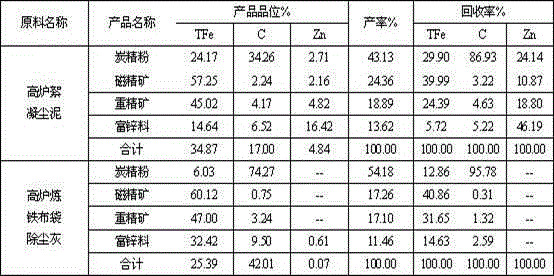

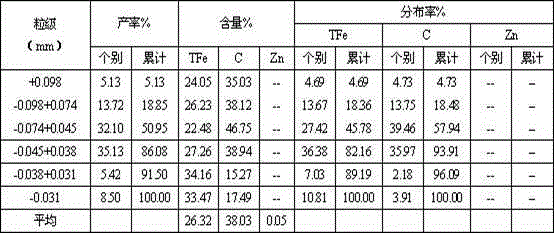

[0025] Blast furnace bag ash TFe20—35%, C30—38%, SiO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com