Sand penetration-preventing alcohol-based foundry coating for resin-bonded sand molds and preparation method thereof

A casting coating and anti-penetration technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of increasing auxiliary man-hours for cleaning castings, unsatisfactory casting surface quality, and poor anti-sand sticking effect of coatings, etc., achieving high cost performance , Resist molten steel penetration, good suspension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare 100 kg of paint.

[0028] The first step: crush chrome corundum sand with a particle size of 1-2 mm into 0.35 kg of chrome corundum of 70 mesh, 0.46 kg of chrome corundum of 100 mesh, 1.5 kg of chrome corundum of 140 mesh, 2 kg of chrome corundum of 200 mesh, 2 kg of chrome corundum of 270 mesh, 320 mesh of chrome corundum 0.99kg of mesh chromium corundum 7.3Kg of mixed mesh chromium corundum is mixed with 21.8Kg of 200 mesh chromium corundum, 14.5Kg of 325 mesh chromium corundum, and 29.1Kg of 325 mesh white corundum to obtain refractory powder, which is set aside;

[0029] The second step: take 0.72Kg of sepiolite, add 0.72Kg of ethanol to mix and disperse together, then add 0.36Kg of water, stir well, and the stirring time is 20 minutes to obtain a highly puffed paste, which is ready for use;

[0030] The third step: mix the highly expanded paste obtained above with 3Kg of sodium bentonite, 0.34Kg of polyvinyl butyral, 0.36Kg of phenolic resin, 0.72Kg of 325 ...

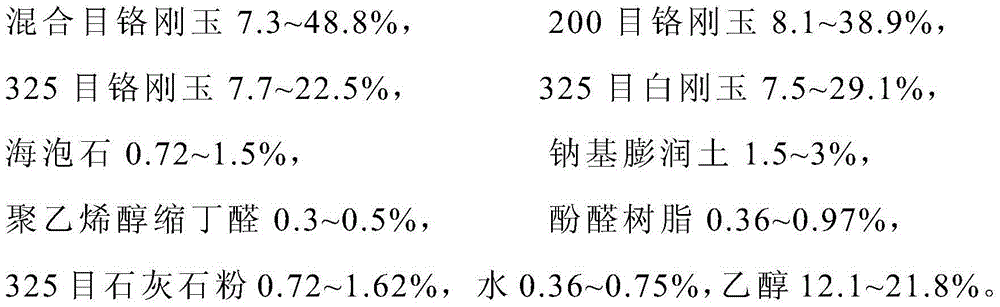

Embodiment 2

[0036] Prepare 100 kg of paint.

[0037] Step 1: Crushing chrome corundum sand with a particle size of 1 to 2 mm into 1.05 kg of 70 mesh chrome corundum, 1.5 kg of 100 mesh chrome corundum, 3 kg of 140 mesh chrome corundum, 3.6 kg of 200 mesh chrome corundum, 3.75 kg of 270 mesh chrome corundum, 320 mesh chromium corundum 2.1kg mixed mesh chromium corundum 15Kg, mixed mesh chromium corundum 30Kg, 325 mesh chromium corundum 22.5Kg, 325 mesh white corundum 7.5Kg are mixed to obtain refractory powder, set aside;

[0038] The second step: take 1.2Kg of sepiolite, add 1.2Kg of ethanol to mix and disperse together, then add 0.5Kg of water, stir thoroughly, and the stirring time is 20 minutes to obtain a highly puffed paste, which is ready for use;

[0039] Step 3: Mix the highly expanded paste obtained above with 2.7Kg of sodium bentonite, 0.3Kg of polyvinyl butyral, 0.5Kg of phenolic resin, 1.1Kg of 325 mesh limestone powder, and 3.5Kg of ethanol, and stir evenly at high speed Abo...

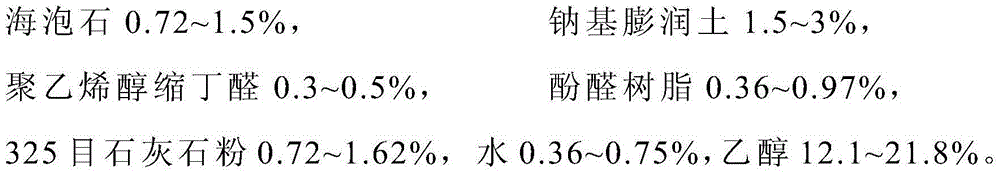

Embodiment 3

[0045] Prepare 100 kg of paint.

[0046]Step 1: Crushing chrome corundum sand with a particle size of 1 to 2 mm into 2.1 kg of 70 mesh chrome corundum, 2.1 kg of 100 mesh chrome corundum, 5 kg of 140 mesh chrome corundum, 5.7 kg of 200 mesh chrome corundum, 6.4 kg of 270 mesh chrome corundum, 320 mesh chromium corundum 2.5kg mixed mesh chromium corundum 23.8Kg, mixed mesh chromium corundum 38.9Kg, 325 mesh chromium corundum 7.7Kg, 325 mesh white corundum 7.7Kg mixed to obtain refractory powder, set aside;

[0047] Step 2: Take 1.5Kg of sepiolite, add 1.5Kg of ethanol to mix and disperse together, then add 0.75Kg of water, stir thoroughly, and the stirring time is 20 minutes to obtain a highly puffed paste, which is ready for use;

[0048] The third step: mix the highly expanded paste obtained above with 1.5Kg of sodium bentonite, 0.4Kg of polyvinyl butyral, 0.75Kg of phenolic resin, 1.5Kg of 325 mesh limestone powder, and 5Kg of ethanol, and stir at a high speed for about Get...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com