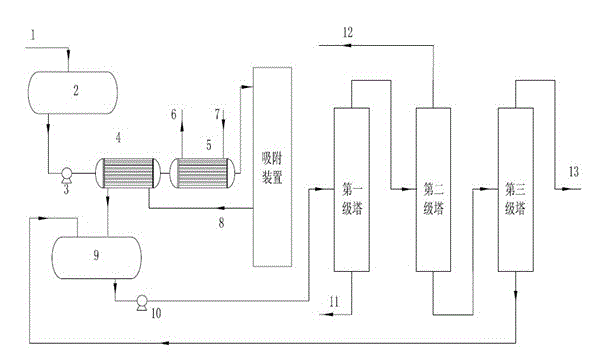

Production process of high-purity refined trichlorosilane

A technology of trichlorosilane and production process, which is applied in the directions of halogenated silanes and halogenated silicon compounds, etc., can solve the problems of high thermal energy and electric power consumption, large one-time investment cost, large reflux ratio, etc., so as to reduce energy consumption and improve The effect of material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the present invention, the preferred embodiments of the present invention are described below, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention rather than limiting the patent requirements of the present invention.

[0036] According to the present invention, the crude trichlorosilane raw material solution in step a) can be prepared by methods well known to those skilled in the art. In the raw material liquid of crude trichlorosilane, impurities include phosphorus-containing compounds, boron-containing compounds, solid silicon powder particles and metal chlorides, but are not limited thereto. Specific examples of the phosphorus-containing compound are phosphorus trichloride and phosphorus pentachloride, specific examples of the boron-containing compound are boron trichloride and diborane, and specific examples of the metal chloride are ferrous chloride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com