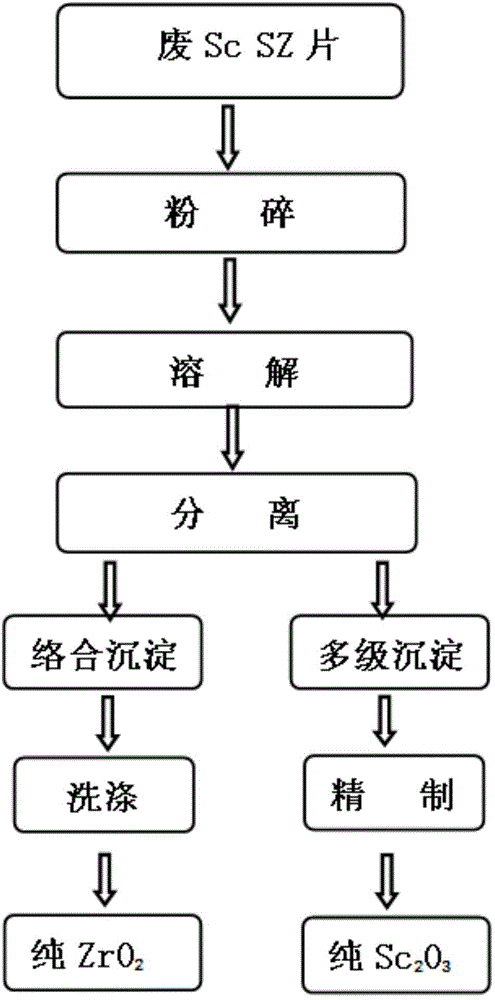

Recovery method of scandia and zirconia in scandium oxide stabilized zirconia sintered body

A technology for stabilizing zirconia and recovery methods, which is applied in the field of recovery of scandium oxide and zirconia in scandia-stabilized zirconia sintered bodies, and can solve the problem of mixed regeneration of zirconia sintered powder and unsintered powder, zirconia sintered electrolyte sheet Aging failure and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Using scandia-stabilized zirconia electrolyte sheets that have been detected to be aged in solid oxide fuel cells as raw materials, firstly through simple separation of electrolyte sheets and electrode materials; and then recycling according to the technology described in the present invention;

[0059] Grinding of Scandium Oxide Stabilized Zirconia Waste Porcelain Chips

[0060] A certain weight of the above-mentioned waste porcelain pieces is dry-pulverized in a rotary pulverizer at a rotational speed of 2800rpm, unloaded after continuous rotary pulverization for 45 minutes, and the pulverized powder and zirconia balls of 10mmΦ are simultaneously put into a 50L ball mill to Rotate at a speed of 45 rpm for 2 hours, and then sieve through a coarse sieve with a pore size of 3 mm to separate the zirconium balls and pulverized powder to obtain a dry coarse pulverized powder with an average particle size of about 100 μm measured by the laser scattering method.

[0061] Mix ...

Embodiment 2

[0075] Different from Example 1, the pulverization of scandium oxide stabilized zirconia sintered body

[0076] A ball mill is used to complete two dry grindings. For the first grinding, the waste porcelain pieces are mixed with 10mmΦ zirconia balls at a ratio of 1:4, and ground at a rotation speed of 80rpm for 3 hours. After sieving and sorting the zirconia balls, the first grinding The powder was then mixed with 5 mmΦ zirconia balls, and ground at a rotational speed of 66 rpm for 5 hours to obtain a dry pulverized powder with an average particle size of about 10 μm to 100 μm measured by laser light scattering.

[0077] Dissolution leaching of powders of scandia-stabilized zirconia sintered bodies, and Zr 4+ 、Sc 3+ The precipitation recovery step all can be identical with embodiment 1 or close.

Embodiment 3

[0079] Different from Examples 1 and 2, the dissolution and leaching of scandium oxide stabilized zirconia sintered body powder

[0080] The same method as in Example 1 or 2 was used to obtain the pulverized powder of scandium oxide-stabilized zirconia sintered body.

[0081] Mix 12% hydrochloric acid, 5.5kg lithium tetraborate and 75% sulfuric acid, then add 13% volume of sulfuric acid-ammonium sulfate buffer solution and stir evenly to prepare a mixed acid solution with a total volume of 100L, and add it to a 200L reactor Warm up to 230°C, gradually add 25kg of above-mentioned crushed scandium oxide-stabilized zirconia powder under slow stirring, continue stirring and heating for 3.5 hours, a melt with a certain viscosity is formed in the kettle, stop heating at this time, continue stirring and cooling to Below 80°C.

[0082] After cooling down the temperature of the above melt, release it slowly and dilute it with dilute hydrochloric acid. Add about 1000L to 2000L of dilu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com