Method for fabricating aerated brick by using gold mine tailings and fluorite tailings

A technology of fluorite tailings and gold mine tailings, applied in applications, household utensils, ceramic products, etc., can solve the problems of low strength, high shrinkage rate, and high cost of sand aerated bricks, so as to reduce the accumulation of waste materials and increase utilization efficiency, huge economic and environmental value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

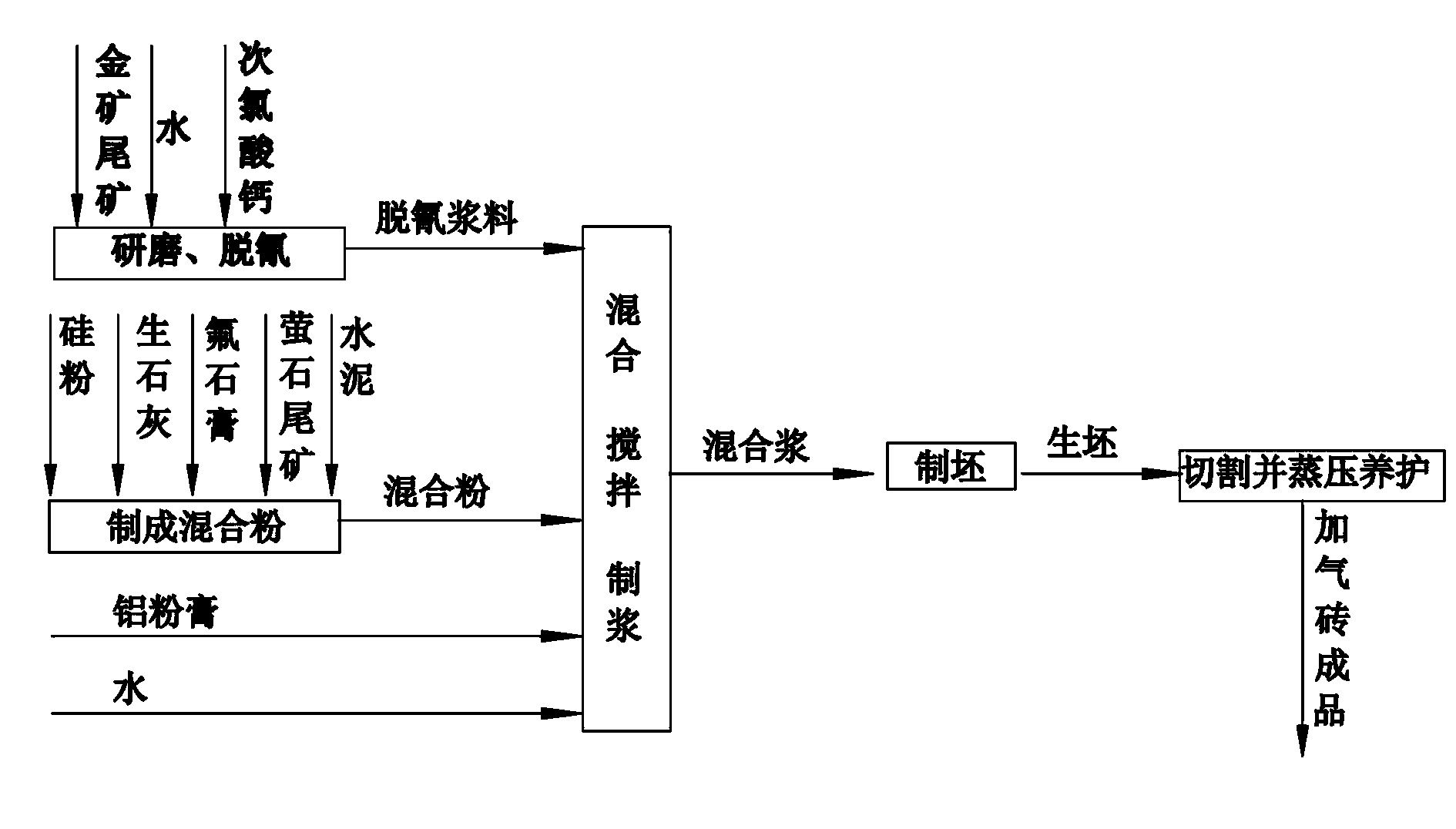

[0023] Such as figure 1 shown, including the following steps:

[0024] (1) Decyanation: Take 2000Kg of gold ore tailings and put them into a ball mill to grind them into powder, add 1000Kg of water to make a slurry, then add 20Kg of calcium hypochlorite to the slurry, stir for 15 minutes, and pour into the metering tank after stirring Stand still for 30 minutes to make decyanation slurry, in order to oxidize the cyanide components into non-toxic substances such as carbon dioxide and nitrogen;

[0025] Preparation of mixed powder: take 2000Kg of quicklime by weight, 300Kg of fluorogypsum, 4000Kg of fluorite tailings by weight, 500Kg of silica fume and 1000Kg of cement by weight and add them to a ball mill, stir and finely grind and mix to make mixed powder;

[0026] (2) Pulping: Mix decyanation slurry, mixed powder, 10Kg of aluminum powder paste and 3000Kg of water to form a mixed slurry;

[0027] (3) Blank making: pour the mixed slurry into the blank mold, and foam at 75°C f...

Embodiment 2

[0031] The difference from Example 1 is that this example adopts the preferred scheme. In step (1), the mixing sequence for making the mixed powder is to mix and stir the quicklime and fluorogypsum for 20 minutes, and then mix the fluorite tailings, silicon powder and Cement, which can effectively remove residual sulfuric acid in fluorogypsum.

Embodiment 3

[0033] The difference from Examples 1 and 2 is that this example adopts the preferred scheme, and in step (1), the mixing time of quicklime and fluorogypsum is 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com