Dielectric ceramic material for multilayer ceramic capacitor with high temperature insulation performance

A technology of ceramic materials and multilayer ceramics, which is applied in the field of dielectric ceramic materials for multilayer ceramic capacitors with high temperature and high insulation performance, can solve the problems of low resistivity and instability, and achieve good high temperature insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

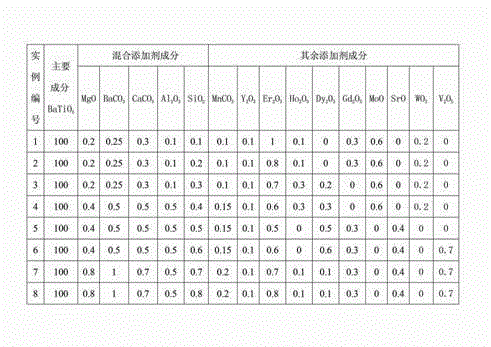

Examples

Embodiment Construction

[0027] The present invention adopts hydrothermal method barium titanate BaTiO 3 Main component, control additives in BaTiO 3 The diffusion rate in the grains enables the ceramics to obtain a uniform core-shell lattice structure. MLCC has high reliability and good high-temperature insulation performance, which meets the X8R standard.

[0028] The additive composition adopted in the present invention improves the reduction resistance of the dielectric ceramic material, and is beneficial to improving the high-temperature insulation performance and stable high-temperature temperature characteristic of the ceramic material MLCC.

[0029] A high temperature and high insulation performance BME MLCC dielectric ceramic material BaTiO 3 The performance is the key. The production process of nano-barium titanate powder includes solid phase method, oxalic acid method, hydrothermal method or sol-gel method. The barium titanate prepared by the hydrothermal process, especially a barium ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com