A kind of anti-flame magnesia-zirconia protection ultra-high temperature wire and preparation method thereof

A technology of magnesium oxide and zirconium oxide, which is applied in the field of wires, can solve the problems of damaging the tightness of the insulating protective layer, and achieve the effects of light weight, improved temperature resistance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides an open flame resistant magnesia-zirconia protected ultra-high temperature wire, the preparation method of which comprises the following steps:

[0035] (1) Preparation of high-temperature conductors: smelting alloy steel powder, wire drawing, and annealing to obtain steel alloy wires, twisting the steel alloy wires to make conductors, then first copper-plating the conductors, and then plating nickel alloys to obtain high-temperature conductors;

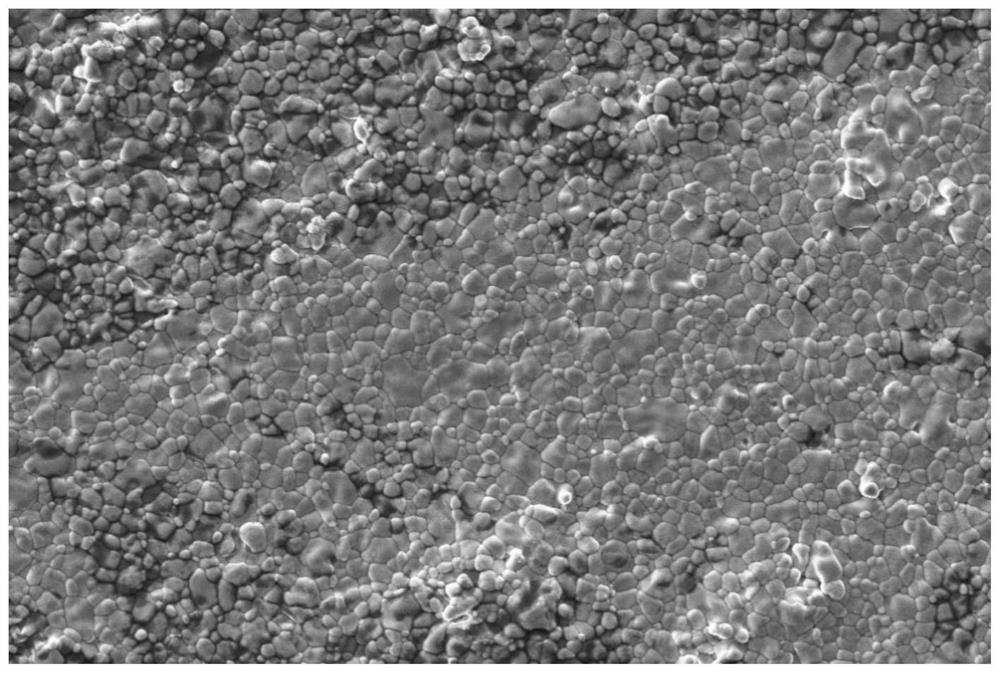

[0036] (2) Take magnesium oxide, aluminum oxide, composite tantalate and zirconium oxide powder in proportion, use dehydrated alcohol as the medium, make the powder mix uniformly by ball milling, dry and sieve the mixed powder to obtain the spray material, Then use plasma spraying technology to evenly spray the spray material on the high temperature conductor obtained in step (1); wherein, the mass ratio of magnesium oxide, aluminum oxide and zirconium oxide powder is 3-5:5-7:3-4, and the composite tantal...

Embodiment 1

[0054] In this embodiment, the preparation method of the flame-resistant magnesia-zirconia protected ultra-high temperature wire is as follows:

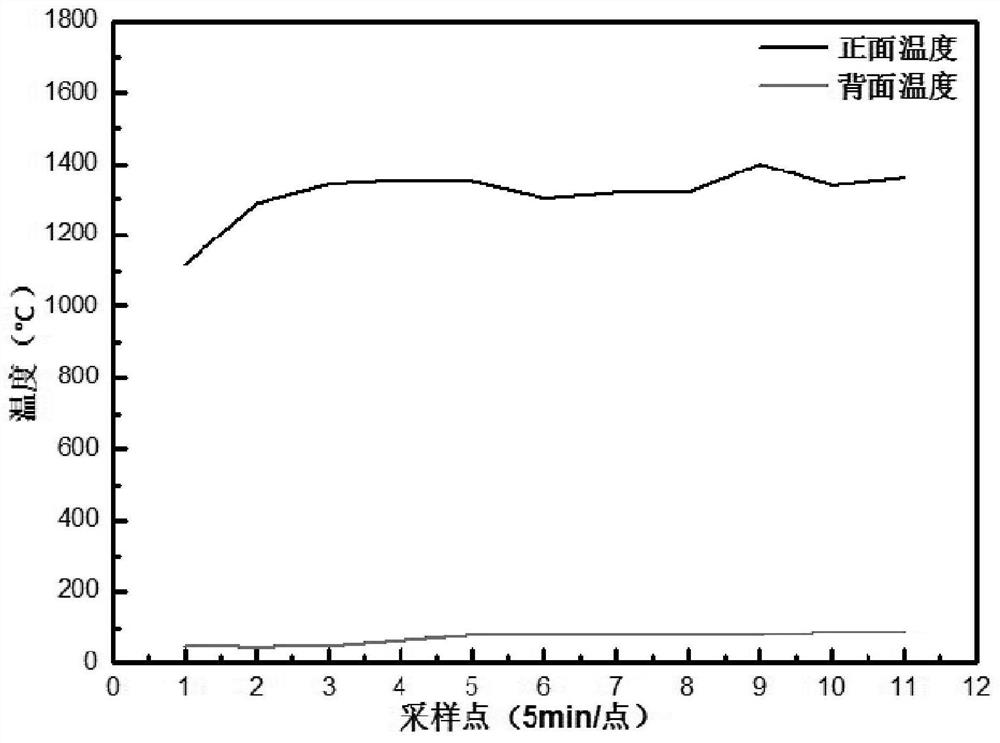

[0055] The prepared alloy steel powder was smelted at a temperature of 1435°C, the smelted alloy was drawn into an alloy wire with a diameter of 0.78mm, the annealing temperature was 870°C, and 12 alloy monofilaments were twisted into a group to obtain a conductor. In 3.0mol / L neutral composite copper solution, the conductor is copper-plated (current 4.2A, voltage 27V, electroplating time 40min); in 8.0mol / L neutral composite nickel alloy solution, copper-plated conductor is carried out Nickel (current 9.2A, voltage 52V, electroplating time 42min), prepared as a high temperature conductor.

[0056] Take by weighing magnesia 24.362g, aluminum oxide 29.852g, zirconia powder 24.312g and composite tantalate 2.365g, take dehydrated alcohol as medium, place ball milling in planetary mill (ball milling speed 525r / min, ball milling time 760m...

Embodiment 2

[0062] In this embodiment, the preparation method of the flame-resistant magnesia-zirconia protected ultra-high temperature wire is as follows:

[0063] The prepared alloy steel powder was smelted at a temperature of 1440°C, the smelted alloy was drawn into an alloy wire with a diameter of 0.78mm, the annealing temperature was 885°C, and 10 alloy monofilaments were twisted into a group to obtain a conductor. In 4.0mol / L neutral composite copper solution, copper-plate the conductor (current 4.6A, voltage 26V, electroplating time 39min); in 9.0mol / L neutral composite nickel alloy solution, copper-plated conductor Nickel (current 8.7A, voltage 53V, electroplating time 46min) was prepared as a high-temperature conductor.

[0064] Take by weighing magnesia 23.968g, aluminum oxide 29.567g, zirconia powder 23.985g and composite tantalate 2.215g, take dehydrated alcohol as medium, place ball milling in planetary mill (ball milling speed 570r / min, ball milling time 660min ), so that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com