Preparation method of soluble calcium citrate

A technology of calcium citrate and citric acid, which is applied in the field of biochemical medicine and food, and can solve the problems of limited use, insoluble in water, and difficult absorption by humans and animals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

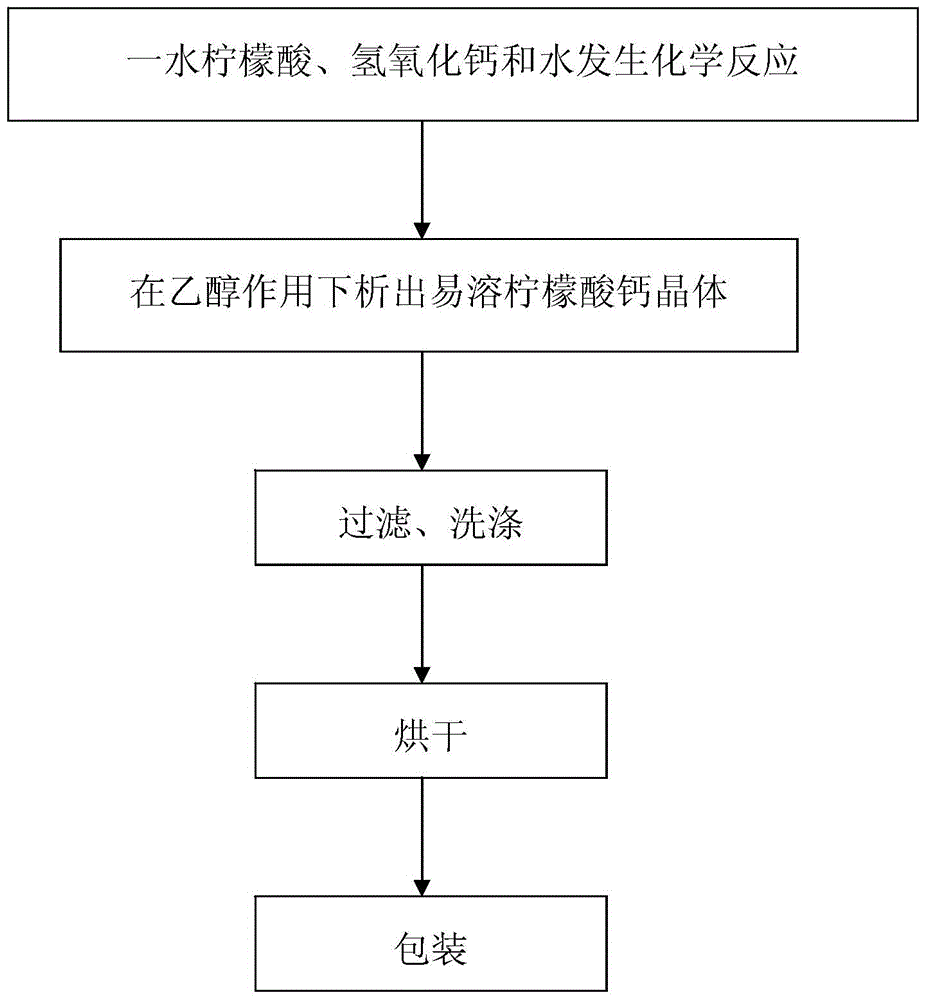

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of the present embodiment soluble calcium citrate comprises the following steps:

[0022] (1) Weigh 420.28g of citric acid monohydrate, 222.24g of calcium hydroxide and a certain amount of water, and put the raw materials into the reaction kettle together;

[0023] (2) Start the chemical reaction for half an hour, the chemical reaction formula is:

[0024] 2C 6 h 8 o 7 ·H 2 O+3Ca(OH) 2 = Ca 3 (C 6 h 5 o 7 ) 2 4H 2 O↓+4H 2 0, the reaction temperature is normal temperature;

[0025] (3) Shut down for half an hour, add ethanol to make the chemical reaction mature, and precipitate easily soluble calcium citrate crystals;

[0026] (4) Start the machine for half an hour, then filter and wash the materials in the reactor after the reaction to obtain soluble calcium citrate crystals.

[0027] (5) After drying, 570.52g of soluble calcium citrate was obtained, and the finished product was packaged.

Embodiment 2

[0029] The preparation method of the present embodiment soluble calcium citrate comprises the following steps:

[0030] (1) Weigh 840.56g of citric acid monohydrate, 444.48g of calcium hydroxide and a certain amount of water, and put the raw materials into the reaction kettle together;

[0031] (2) Start the chemical reaction for half an hour, the chemical reaction formula is:

[0032] 2C 6 h 8 o 7 ·H 2 O+3Ca(OH) 2 = Ca 3 (C 6 h 5 o 7 ) 2 4H 2 O↓+4H 2 0, the reaction temperature is normal temperature;

[0033] (3) Shut down for half an hour, add ethanol to make the chemical reaction mature, and precipitate easily soluble calcium citrate crystals;

[0034] (4) Start the machine for half an hour, then filter and wash the materials in the reactor after the reaction to obtain soluble calcium citrate crystals.

[0035] (5) After drying, 1141.04g of soluble calcium citrate was obtained, and the finished product was packaged.

Embodiment 3

[0037] Weigh 3.7 g of the easily soluble calcium citrate prepared in Example 1, add 100 ml of water, and stir at room temperature for 5 minutes to completely dissolve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com