A kind of linoleic acid modified glucan and the method for preparing polymer liposome

A technology of glucan and linoleic acid, applied in the field of medicine, can solve the problems such as the further improvement of liposome transdermal performance, the improvement of modifiability and targeting effect, the degradation of enzymes and the phagocytosis of macrophages. , to achieve good transdermal performance, good transdermal and biocompatibility, and low cytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

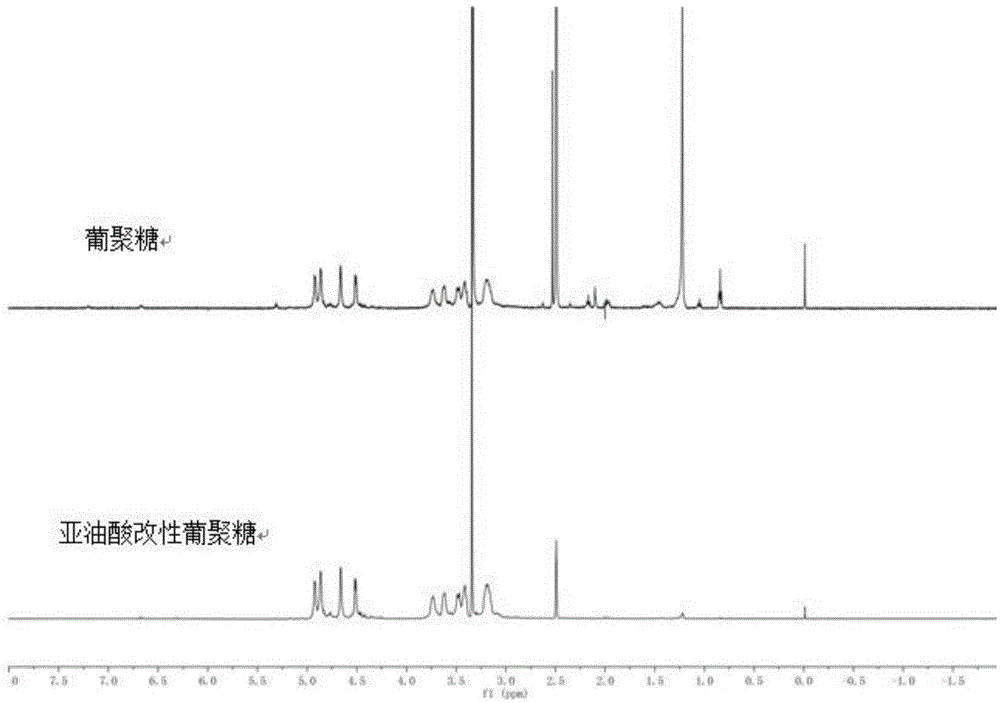

[0030] Synthesis of linoleic acid modified dextran. Take 1g of dextran with a molecular weight of 5000, 3g of linoleic acid and add them into a beaker, then add 182mL of dimethyl sulfoxide solvent, 0.6g of EDC and 0.15g of DMAP into the beaker, stir magnetically, and react at room temperature for 3 hours. After the reaction, put the product into a dialysis bag with a molecular weight of 1000 for dialysis for 3 days, and freeze-dry to obtain linoleic acid-modified dextran. Such as figure 1 As shown in the 1H-NMR analysis results, 0.8ppm and 1.2ppm are the characteristic absorption peaks of —CH3 and —CH2 in linoleic acid respectively, indicating that the linoleic acid modified dextran was successfully synthesized.

Embodiment 2

[0032] Synthesis of linoleic acid modified dextran. Take 5 g of dextran with a molecular weight of 20,000 and 1 g of linoleic acid into a beaker, then add 45 mL of dimethyl sulfoxide solvent, 1 g of EDC and 0.5 g of DMAP into the beaker, stir magnetically, and react at room temperature for 12 hours. After the reaction, put the product into a dialysis bag with a molecular weight of 5000 for dialysis for 10 days, and freeze-dry to obtain linoleic acid-modified dextran.

Embodiment 3

[0034] Synthesis of linoleic acid modified dextran. Add 1 g of dextran with a molecular weight of 10,000 and 1 g of linoleic acid into a beaker, then add 100 mL of dimethyl sulfoxide solvent, 0.5 g of EDC and 0.2 g of DMAP into the beaker, stir magnetically, and react at room temperature for 8 hours. After the reaction, put the product into a dialysis bag with a molecular weight of 3500 for dialysis for 7 days, and freeze-dry to obtain linoleic acid-modified dextran.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com