Antistatic phenolic moulding plastic

A phenolic molding compound, antistatic technology, applied in the field of thermosetting plastics, can solve the problems of low product molding efficiency, lack of mechanical strength, slow molding speed, etc., achieve the effect of improved antistatic effect, cheap raw materials, and enhanced mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

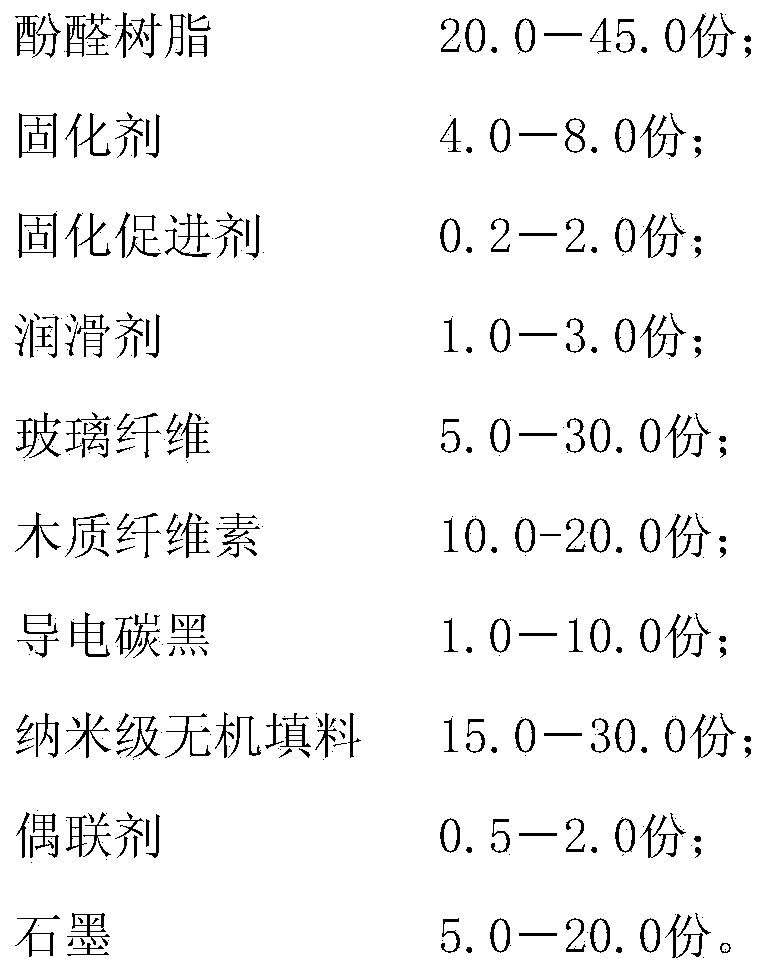

Method used

Image

Examples

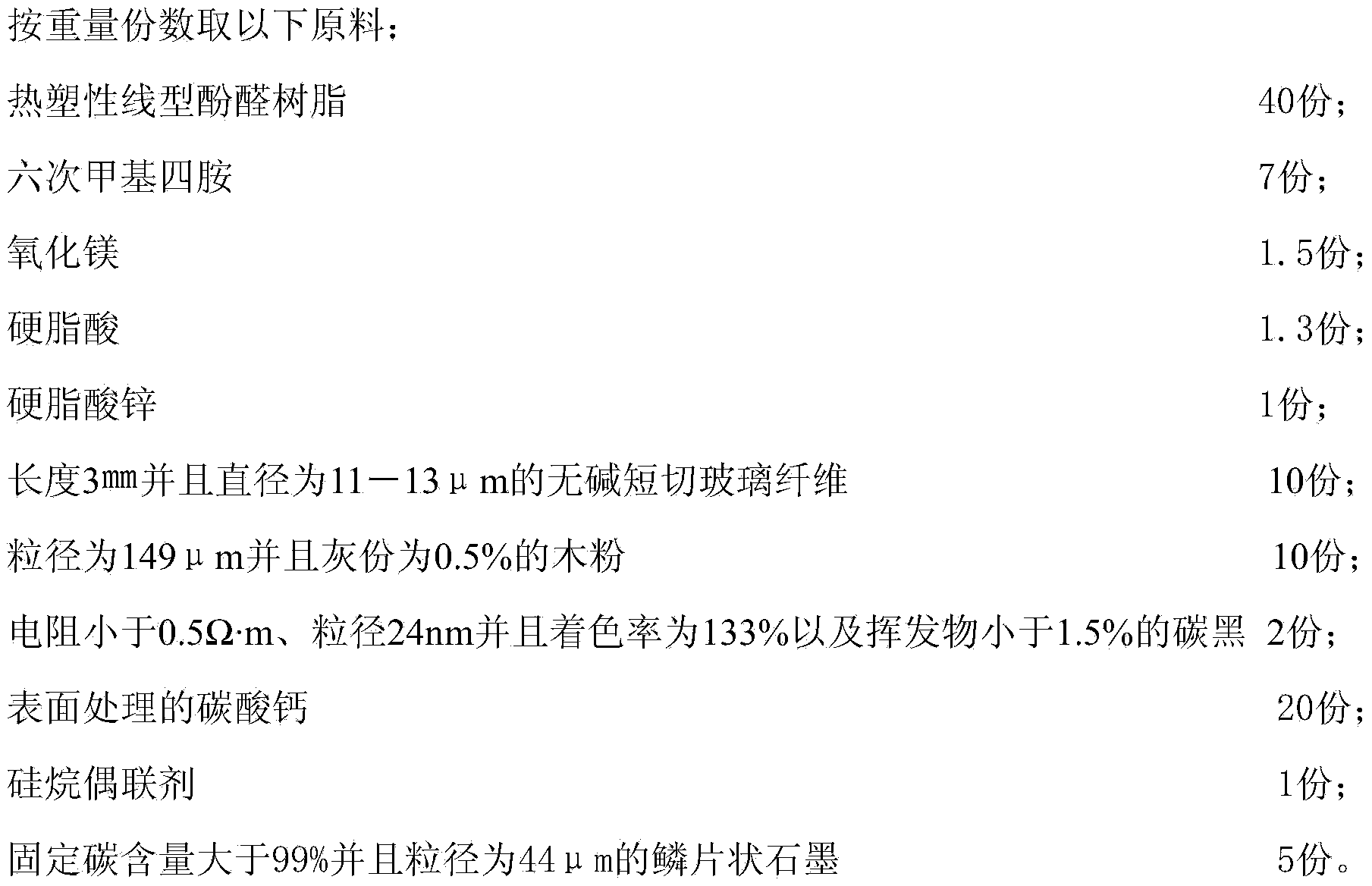

Embodiment 1

[0021]

[0022] During specific implementation, that is, when the antistatic phenolic molding compound is prepared from the above-mentioned raw materials, 40 parts of thermoplastic novolac resins are first pulverized, and put into a kneader, and 7 parts of hexamethylenetetramine, magnesium oxide 1.5 parts, 1.3 parts of stearic acid, 1 part of zinc stearate, 10 parts of alkali-free chopped glass fiber with a length of 3 mm and a diameter of 11-13 μm, 10 parts of low-ash wood powder with a particle size of 149 μm, and a resistance of less than 0.5Ω·m, 24nm particle size, 2 parts of carbon black with a coloring rate of 133% and less than 1.5% volatile matter, 20 parts of surface-treated calcium carbonate, 1 part of silane coupling agent, and a fixed carbon content greater than 99% and particle size Knead 5 parts of 44μm flaky graphite to obtain a kneaded material, and then introduce the kneaded material into a double-roller plastic machine for masticating, the masticating tempe...

Embodiment 2

[0024]

[0025]

Embodiment 3

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com