Anhydrous calcium-based lubricating grease composition and preparation method thereof

A technology of calcium-based grease and composition, applied in the field of grease, can solve the problems of no post-treatment process, complicated process, and complicated post-treatment process of grease, and achieve good anti-oxidation performance, wide temperature adaptation range, and excellent anti-oxidation properties. The effect of water performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

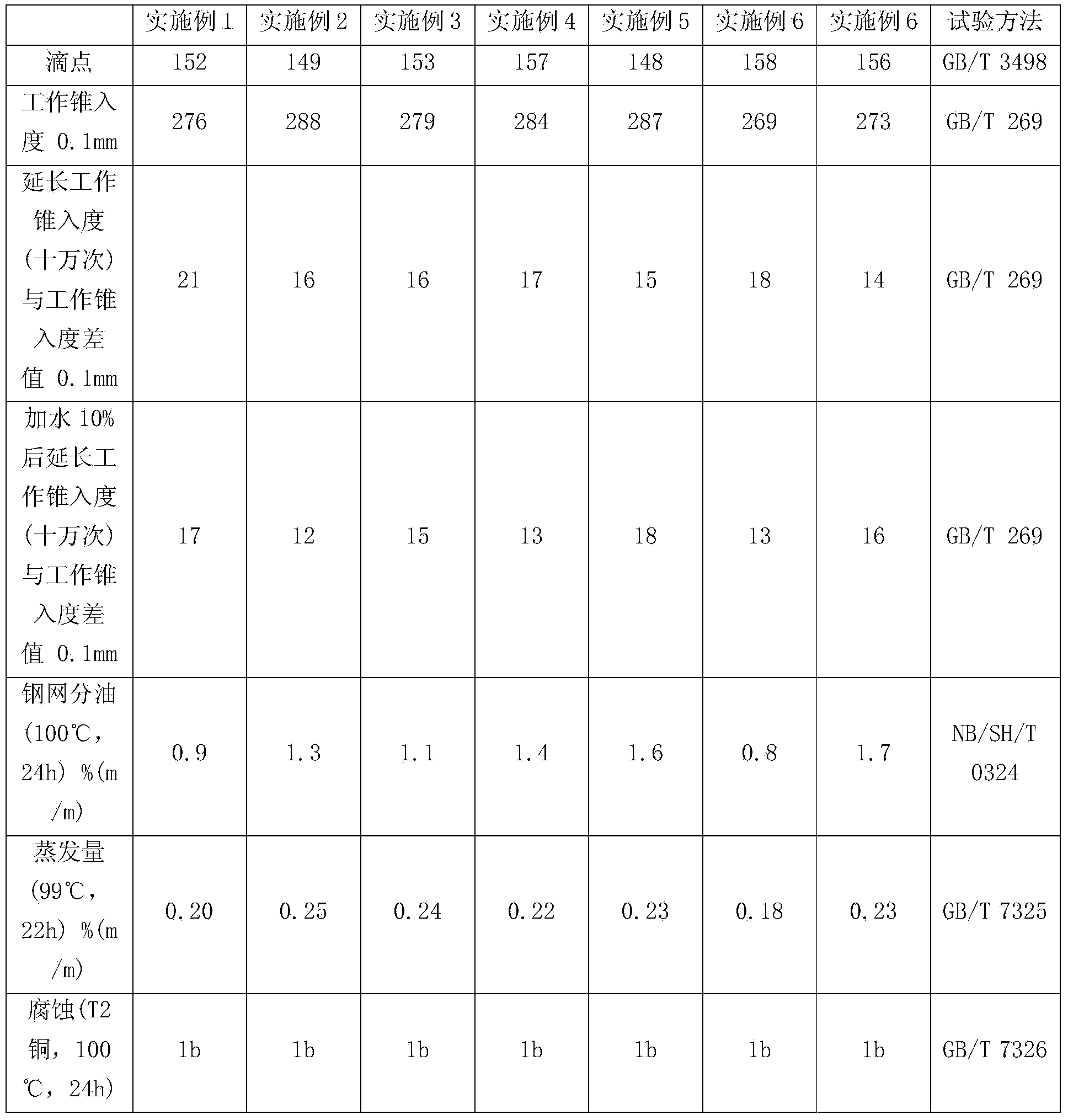

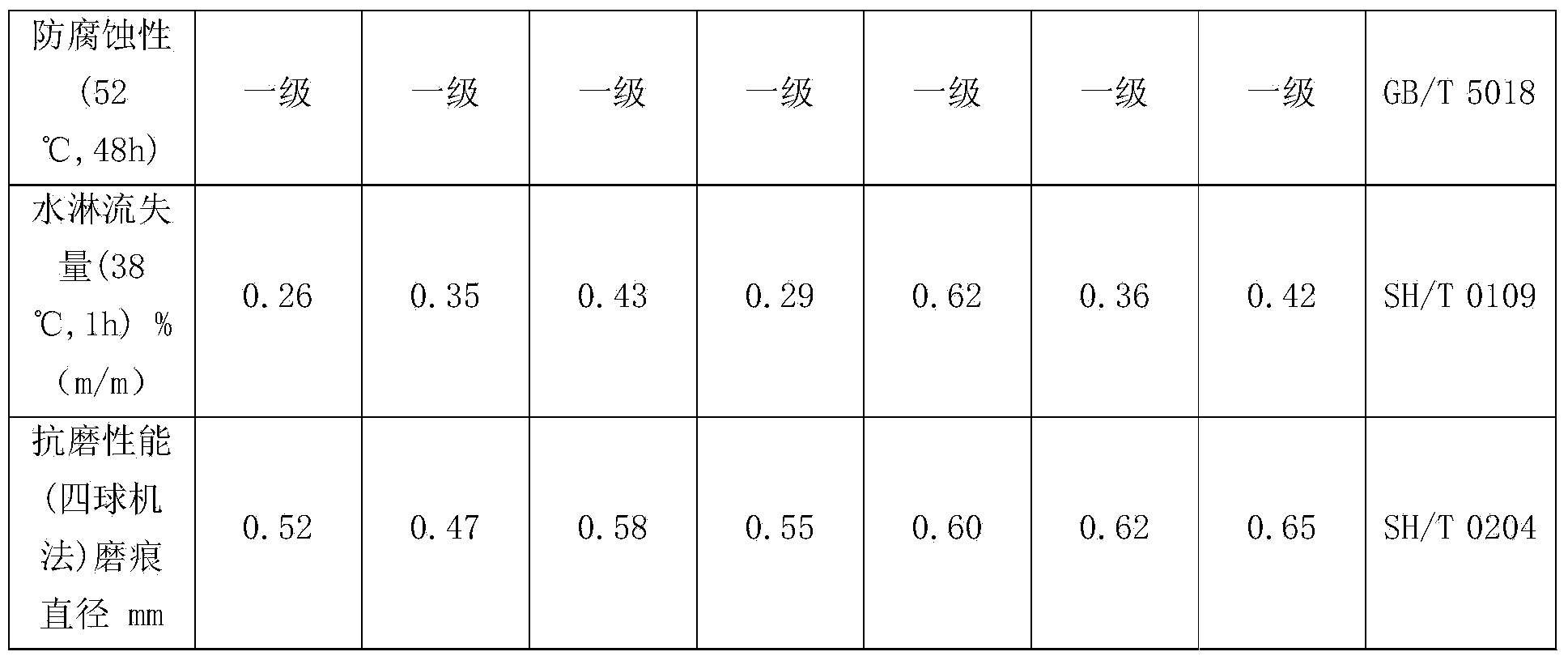

Examples

Embodiment 1

[0020] At room temperature, 80 grams of calcium 12-hydroxystearate, 522g of mineral oil and 92g of olefin synthetic oil were put into the reaction kettle, stirred and heated to 150°C, continued to stir, cooled and cooled, and 306g of mineral oil was added to the reaction kettle at 120°C, Continue stirring. The temperature was lowered to 80°C, and the composition was pressed by a three-roller machine for three times, and then the finished product was canned.

Embodiment 2

[0022] 100 g of calcium 12-hydroxystearate, 540 g of mineral oil and 360 g of olefin synthetic oil were put into the reaction kettle at room temperature, stirred and heated to 155° C., continued to be stirred, and cooled to cool down. The temperature was lowered to 80°C, and the composition was pressed by a three-roller machine for three times, and then the finished product was put into a can.

Embodiment 3

[0024] 120 g of calcium 12-hydroxystearate, 510 g of mineral oil and 220 g of olefin synthetic oil were put into the reactor at room temperature, stirred and heated to 155°C, continued to stir, cooled and cooled, and 150g of mineral oil was added to the reactor at 120°C, Continue stirring. The temperature was lowered to 80°C, and the composition was pressed by a three-roller machine for three times, and then the finished product was canned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com