Anti-seepage water-based high-gloss coating composition for tipping paper and preparation method thereof

A technology for tipping paper and composition, applied in paper coating, papermaking, coating and other directions, can solve the problems of complex process, high cost and high cost, and achieve good anti-seepage effect, good printing suitability and good hygienic index. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

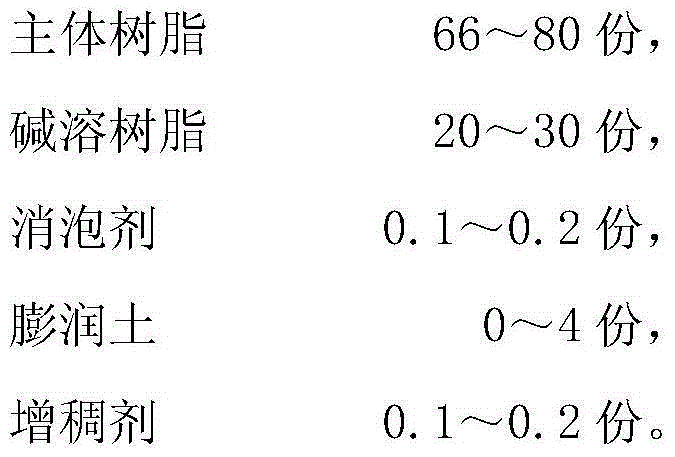

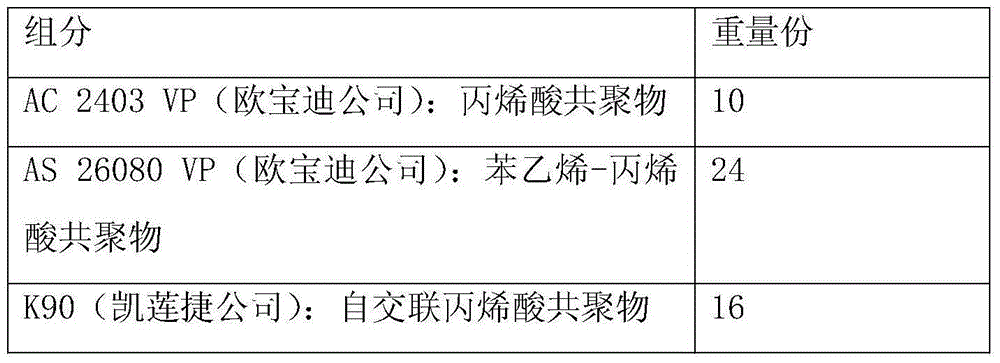

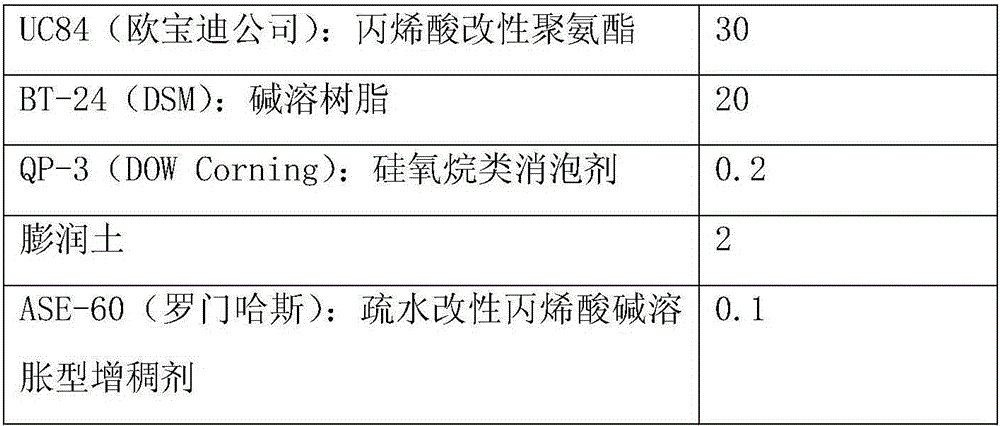

[0032] The anti-seepage water-based high-gloss coating composition for tipping paper of the present embodiment includes each component in parts by weight shown in Table 1; the specific preparation includes the following process steps:

[0033] (1) according to the component shown in table 1 and content (weight part) prepare raw materials:

[0034] Table 1

[0035]

[0036]

[0037] (2) Put the main resin into the reaction kettle, and stir at a low speed of 300-500 rpm for 5-10 minutes;

[0038] (3) Add the alkali-soluble resin into the reaction kettle while stirring, and stir at a low speed of 300-500 rpm for 5-10 minutes;

[0039] (4) Add defoamer to the reaction kettle, and stir at a high speed of 1000-1200 rpm for 40-50 minutes;

[0040] (5) Add bentonite to the reaction kettle while stirring, and stir at a low speed of 300-500 rpm for 5-10 minutes;

[0041] (6) Add a thickener into the reaction kettle, stir at a low speed of 300-500 rpm for 20 minutes; obtain an a...

Embodiment 2

[0044] The anti-seepage water-based high-gloss coating composition for tipping paper of the present embodiment includes each component in parts by weight shown in Table 2; the specific preparation includes the following process steps:

[0045] (1) get the raw materials ready according to the components and content (parts by weight) shown in Table 2:

[0046] Table 2

[0047] components

parts by weight

XK-90(DSM): Acrylic copolymer

15

XK-82(DSM): Styrene-acrylic acid copolymer

30

K90 (Kai Lianjie company) self-crosslinking acrylic resin

8

AS26090VP (Ou Baodi): acrylic modified polyurethane

20

BT-9(DSM): Alkali-soluble resin

25

Foamex815 (TEGO) silicone defoamer

0.2

4

[0048] WT-105A (Hemmings Deqian): associative thickener

0.1

[0049] (2) Put the main resin into the reaction kettle, and stir at a low speed of 300-500 rpm for 5-10 minutes;

[0050] (...

Embodiment 3

[0056] The anti-seepage water-based high-gloss coating composition for tipping paper of the present embodiment includes each component in parts by weight shown in Table 3; the specific preparation includes the following process steps:

[0057] (1) get the raw materials ready according to the components and content (parts by weight) shown in table 3:

[0058] table 3

[0059]

[0060] (2) Put the main resin into the reaction kettle, and stir at a low speed of 300-500 rpm for 5-10 minutes;

[0061] (3) Add the alkali-soluble resin into the reaction kettle while stirring, and stir at a low speed of 300-500 rpm for 5-10 minutes:

[0062] (4) Add defoamer to the reaction kettle, and stir at a high speed of 1000-1200 rpm for 40-50 minutes;

[0063] (5) Add a thickener into the reaction kettle, stir at a low speed of 300-500 rpm for 20 minutes; obtain an anti-seepage water-based high-gloss coating composition for tipping paper.

[0064] The above-mentioned coating composition is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com