Scanned, pulsed electron-beam polymerization

An electron beam, polymerizing monomer technology, applied in the field of polymerization, can solve the problems of low conversion rate, short residence time and short chain length of polymers, and achieve the effects of short residence time, high conversion value and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

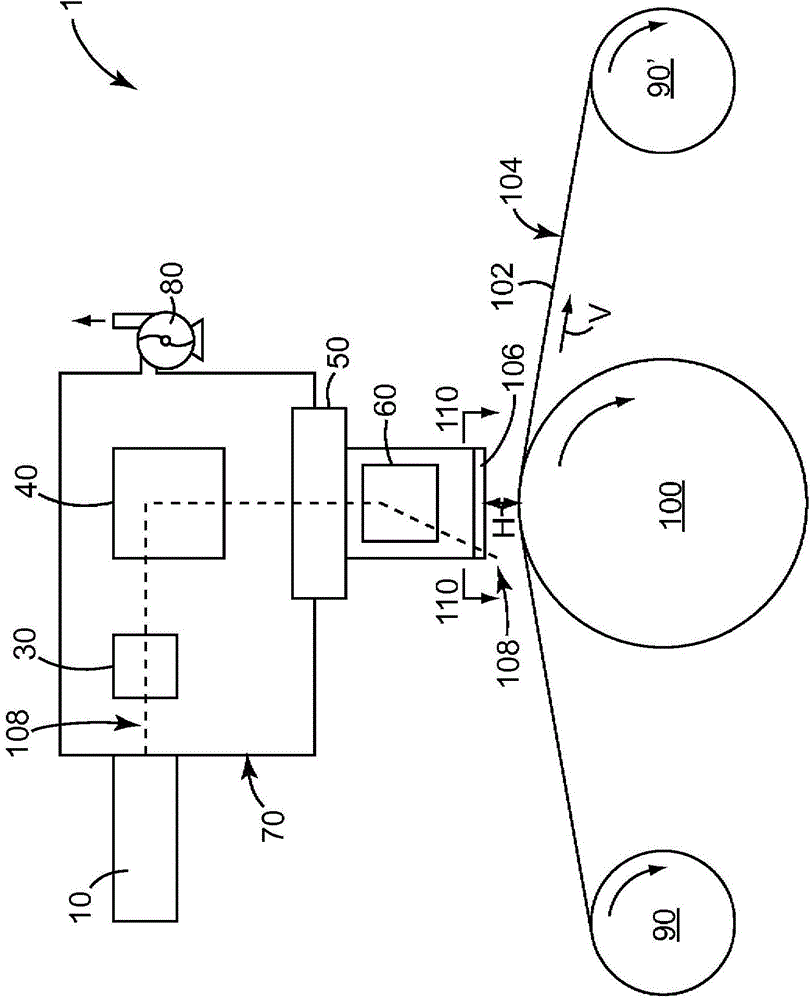

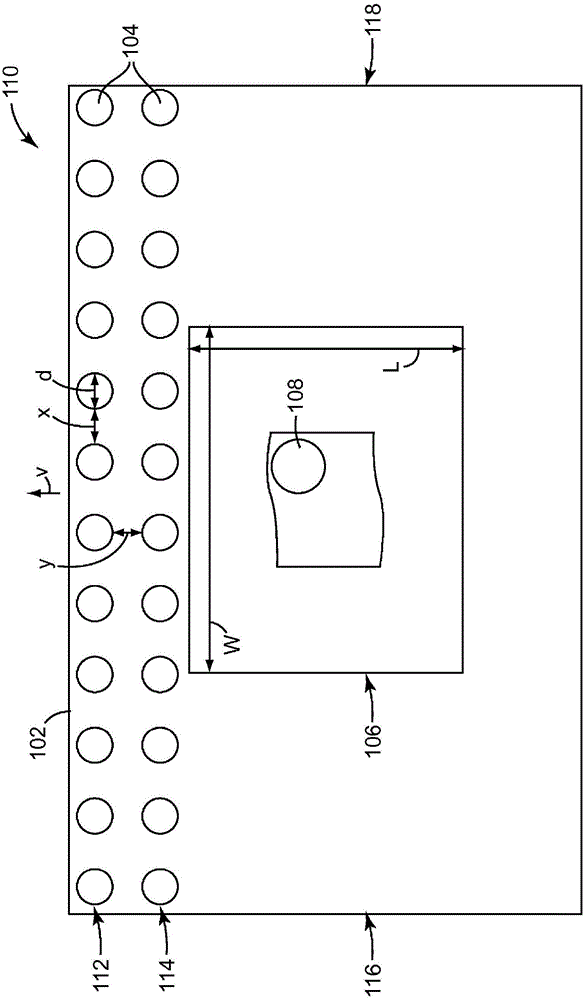

Method used

Image

Examples

example

[0255] The following examples are intended to illustrate exemplary embodiments within the scope of the invention. Notwithstanding that the numerical ranges and parameters setting forth the broad scope of the invention are approximations, the numerical values set forth in the specific examples are reported as precisely as possible. Any numerical value, however, inherently contains certain errors necessarily resulting from the standard deviation found in their respective testing measurements. At the very least, and not as an attempt to limit the application of the doctrine of equivalents to the scope of the claims, each numerical parameter should at least be construed in light of the number of reported significant digits and by applying ordinary rounding techniques.

[0256] test program

[0257] The following tests were used to evaluate the polymeric compositions of the present invention.

[0258] Conversion rates

[0259] Will be a 14.5cm 2 (1.5 x 1.5 in2) samples we...

example 1-

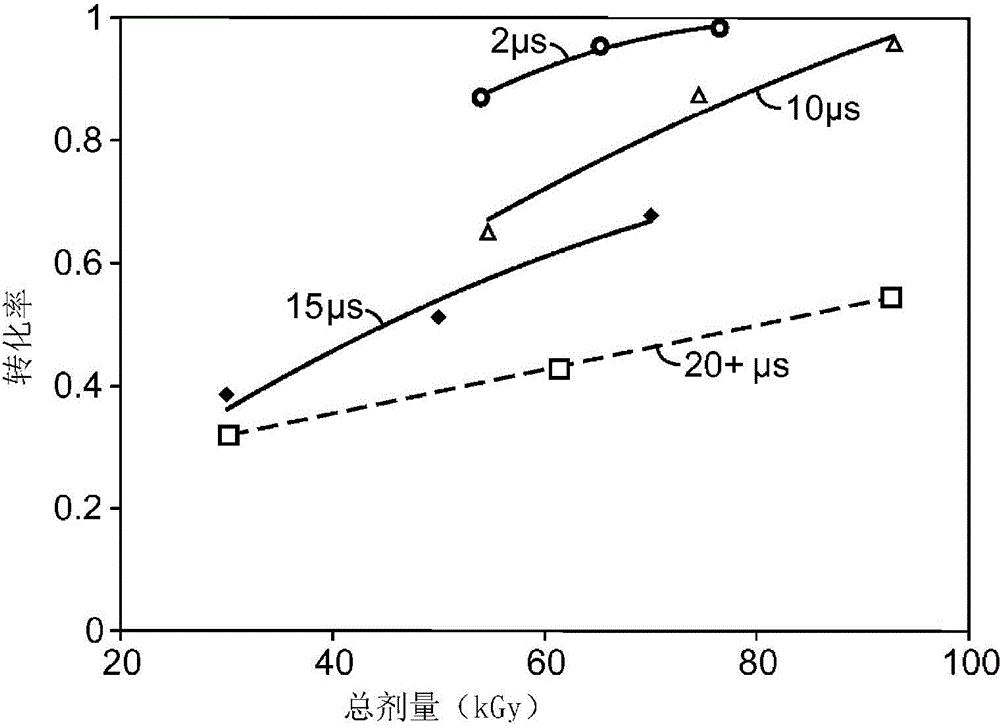

[0286] Example 1 - Pressure Sensitive Adhesive

[0287] Pressure-sensitive adhesive samples were prepared by scanning pulsed electron beam irradiation with paste A at a temperature of 0 °C. Each sample was coated to a thickness of approximately 1 mil (25 microns thick) using a Meyer rod and sandwiched between two layers of 1 mil (25 microns thick) polyethylene terephthalate film (PET) between.

[0288] The percent conversion and percent gel were measured for each coated sample. Example 1 shows the effect of dose per exposure duration on the total dose required to obtain an extrapolated conversion rate of at least 90%, and more preferably at least about 95% or higher (e.g., 94.4% to 99.7%) . Example 1 also shows that the dose for each duration of exposure contributes to obtaining at least about 80%, more preferably at least about 90%, or even at least about 95% (e.g., 97-99.1%) but preferably less than 100% of the extrapolated coagulation. Effect of the total dose require...

example 2

[0295] Example 2 - Silicone Crosslinking

[0296] The sample conditions described above were also used to crosslink non-functionalized PDMS (OHX-4070, 50,000 centistokes) coated on PET to a thickness of 3 mils (75 microns). Table 2 summarizes the experimental conditions and results (percent gel) for crosslinking.

[0297]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com