Gantry type programmable control girth welding machine

A circular seam welding, gantry-type technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems such as the position of the welding torch is not in place, the seal is easy to age, and the resistance of the three-jaw chuck is large. Easy operation, good welding quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

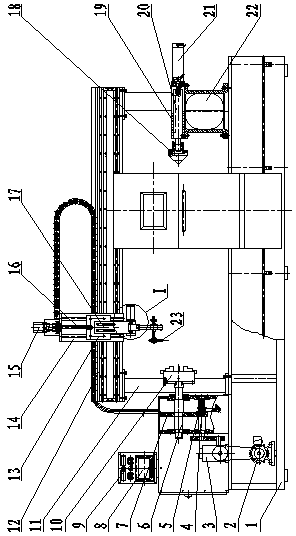

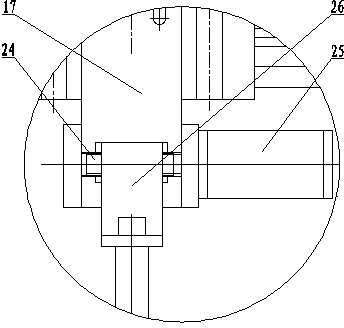

[0010] as attached figure 1 As shown, frequency conversion motor 2, speed reducer 3, gantry 11, and tailstock 22 are fixed on the designated position of frame 1; Before work, first set the welding voltage, current, air pressure control, number of welding circles of each layer of the workpiece to be welded by the encoder, the frequency conversion motor 2 drives the peripheral welding speed of the workpiece to be welded, and the stepper motor 15 drives the automatic lifting of the welding torch between layers. The stepper motor 25 drives the swing speed and amplitude of the swing device, and the cylinder 21 pushes and pulls the data program for the tightening and loosening of the weldment, and inputs it in the PLC programmable controller 9; clamps on the three-jaw chuck 10 The workpiece to be welded and click on the tightening program of the cylinder 21 in the touch screen 8, so that the axis of the workpiece to be welded is placed on the line connecting the axis of the three-ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com